Dynamic prewhirl and axial push type hydrocyclone

A hydrocyclone and axial propulsion technology, which is applied in the direction of the device whose axial direction of the cyclone can be reversed, the cyclone device, etc. Rotation vibration and other problems, to achieve the effect of reducing the axial velocity gradient, the rotor cantilever is not easy to vibrate, and the inlet pressure requirement is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with a typical embodiment, but not limited to this embodiment.

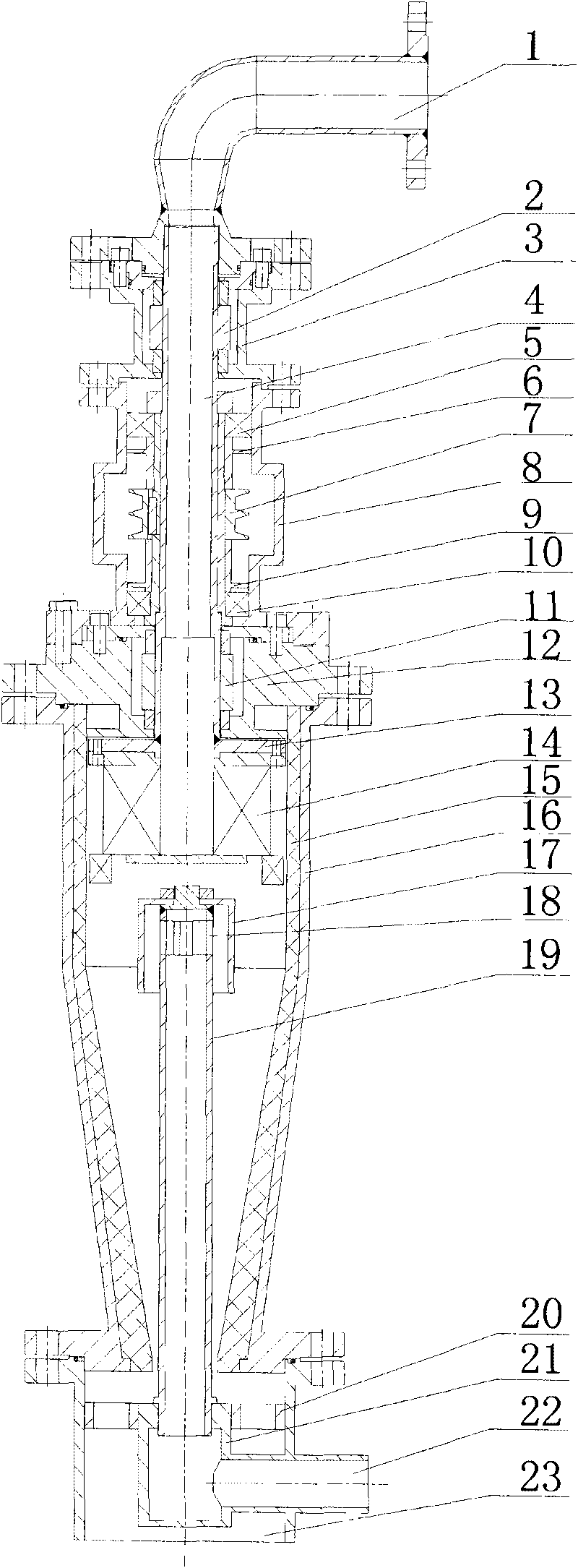

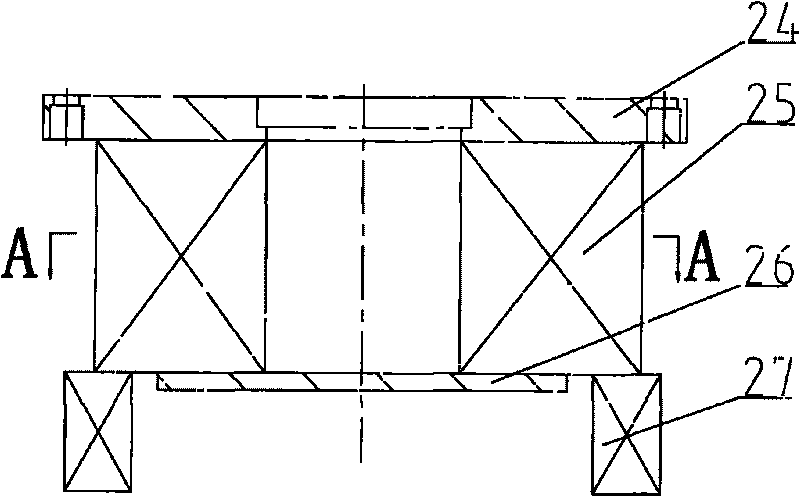

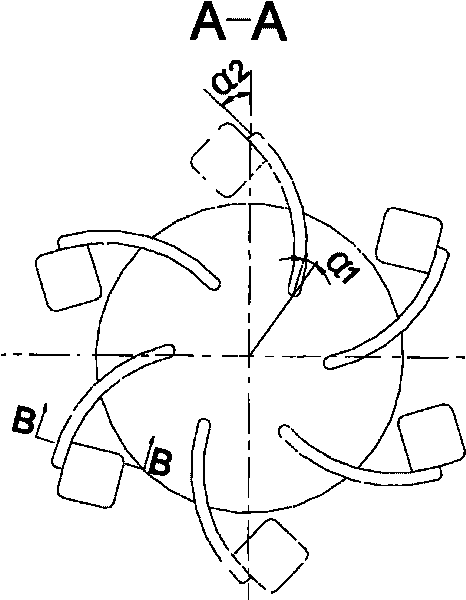

[0039] See attached figure 1 , The dynamic pre-rotation and axial propulsion hydrocyclone of the present invention is divided into two parts: the medium pre-rotation part and the hydrocyclone separation part. The pre-rotating part includes a feed pipe 1, a rotating pipe shaft 4, a connecting plate 13, a rotating grid 14, upper and lower rotating bearings 5, 10, upper and lower bearing covers 6, 9, bearing brackets 8, pulleys 7, and upper , lower rotating seals 2, 12, upper and lower sealing seats 3, 11 and other components; the hydrocyclone separation part includes cyclone wear-resistant lining 15, cyclone shell 16, anti-short-circuit shield 17, light liquid guide Outlet and outlet pipes 18, 19, centering support web 20, light liquid outlet tank 21, light liquid outlet pipe 22, heavy liquid and solid particle outlet pipe 23, etc. The pre-rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com