Novel air film cooling slotting structure

A new type of film cooling technology, which is applied in the direction of supporting components of blades, engine components, machines/engines, etc., can solve the problems of reduced cooling effect and limited lateral cooling protection effect, so as to reduce strength and improve film cooling efficiency , reduce the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

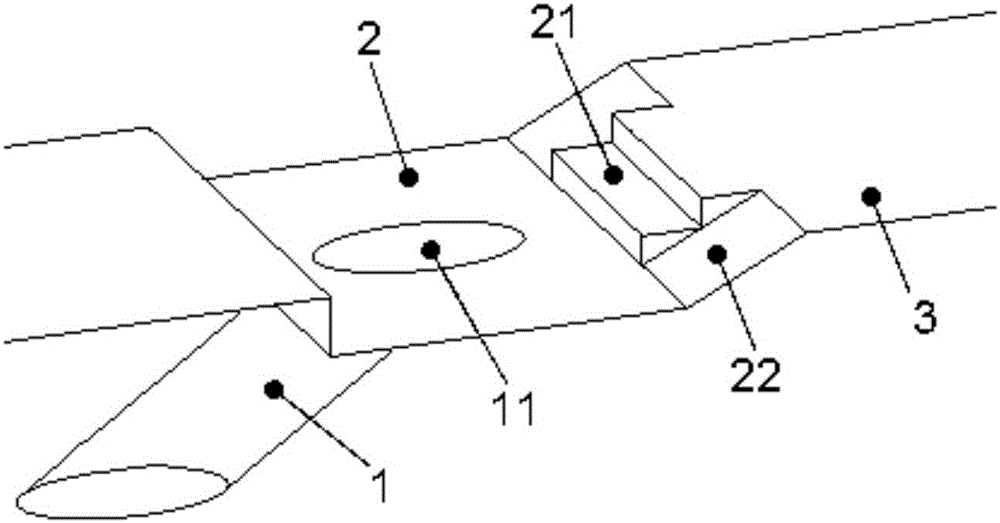

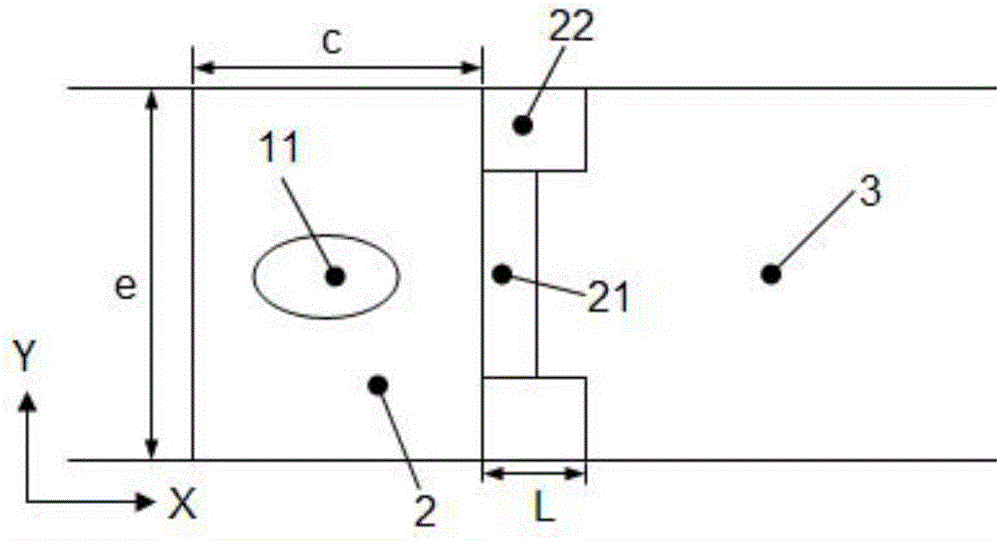

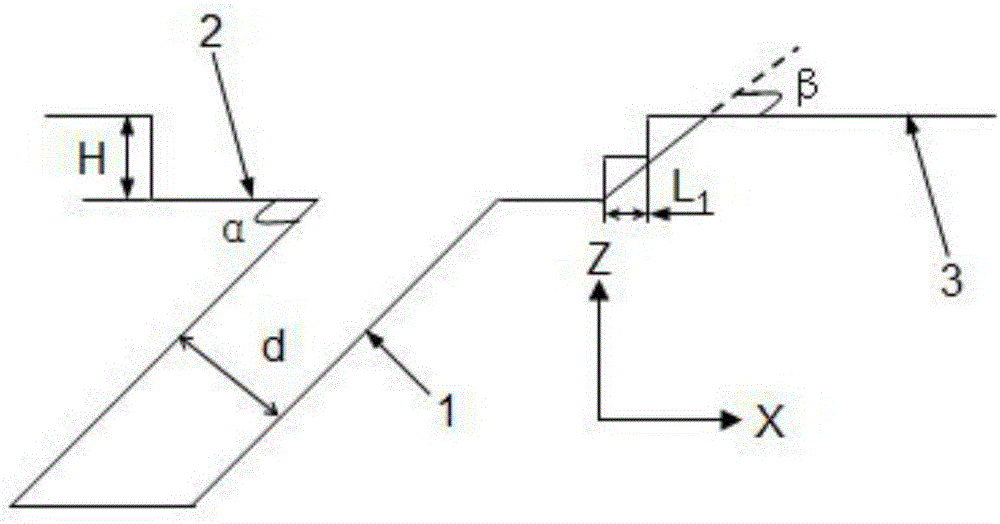

[0033] The structure of this embodiment (see Figure 1-4 ) includes air film hole 1, transverse groove 2 and wall surface 3, air film hole 1 is arranged on the upstream area of wall surface 3, and transverse groove 2 is provided at the outlet of air film hole 1, and the downstream groove wall of transverse groove 2 There is a downstream ladder 21 at the middle position on the top, and the guide surfaces 22 are arranged symmetrically on both sides of the downstream ladder 21. The plane of the downstream ladder facing the incoming flow direction is perpendicular to the wall surface, and the lowest point and the highest The points are respectively flush with the bottom surface of the transverse groove 2 and the downstream wall surface 3, and the downstream step 21 is arranged axisymmetrically with the center of the air outlet hole 11 of the air-passing film hole and parallel to the center line of the wall surface 3; The wall surface 3 is a slope with an included angle of 15°-75...

Embodiment 2

[0040] The composition and relative positional relationship of each part in the structure of this embodiment is the same as that of Embodiment 1, and the number of steps of the downstream steps is 2. The difference is that the sizes of the two steps of the downstream steps in this embodiment are not exactly the same. The length of the step in the Y direction is greater than that of the following step, the ratio of the maximum projected length of the downstream step along the lateral direction of the wall (ie the Y direction) to the aperture of the air film hole is 2.0, and the top view of the diversion surface 22 is a right-angled trapezoid.

Embodiment 3

[0042] The composition and relative positional relationship of each part in the structure of this embodiment is the same as that of Embodiment 1, the difference is that the number of steps of the downstream step is one, and it is a step with an inclined surface.

[0043] What is not mentioned in the present invention is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com