Device for freely separating cold and hot fluid media

A technology of fluid medium and separation device, which is applied in the field of energy storage, and can solve problems such as the difficulty in realizing the automatic rise and fall of the floating heat shield, the continuous response adjustment of the buoyancy of the floating heat shield, and the unavoidable disturbance and mixing of hot and cold fluids. , to achieve remarkable energy saving effect, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

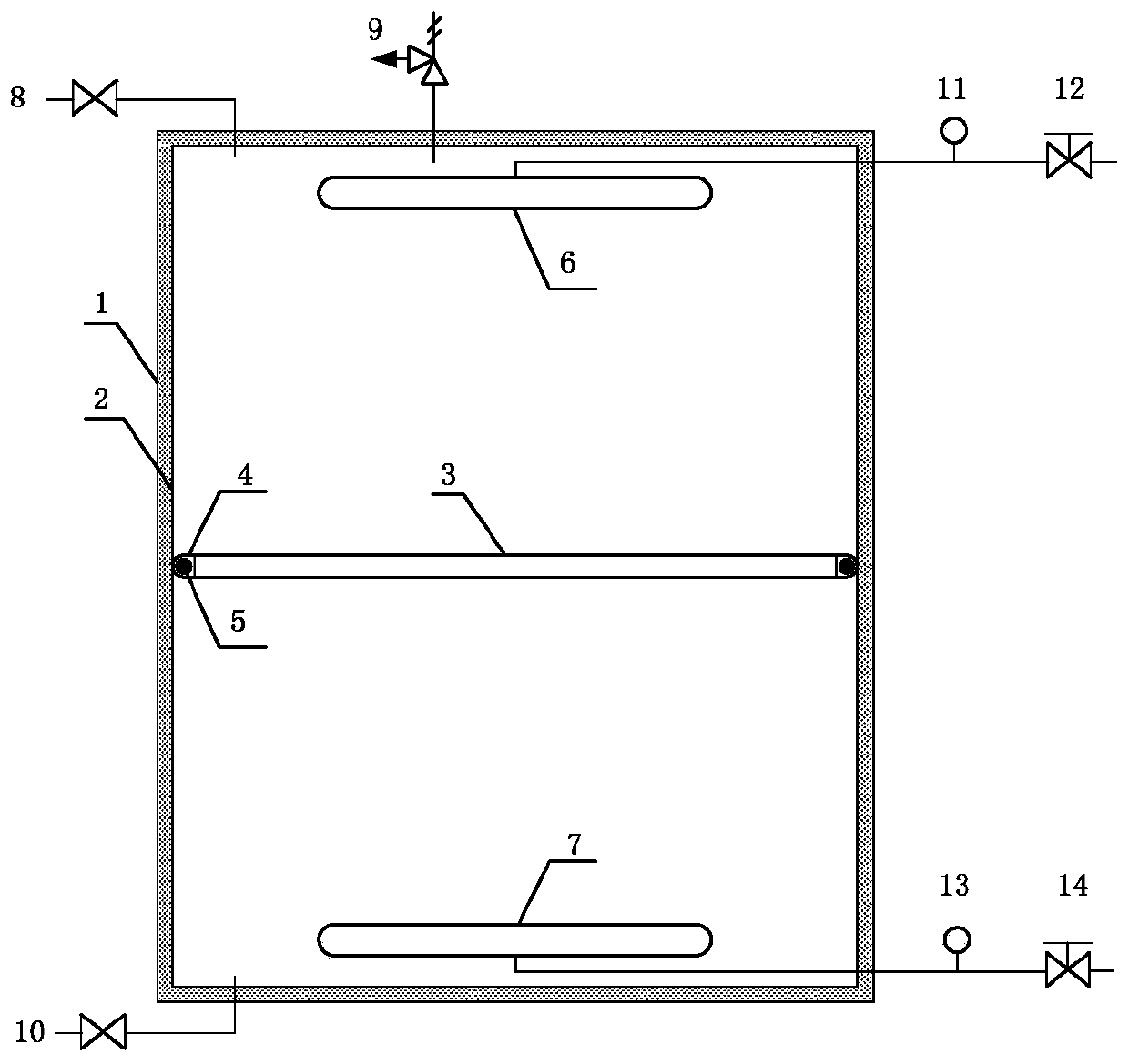

Embodiment 1

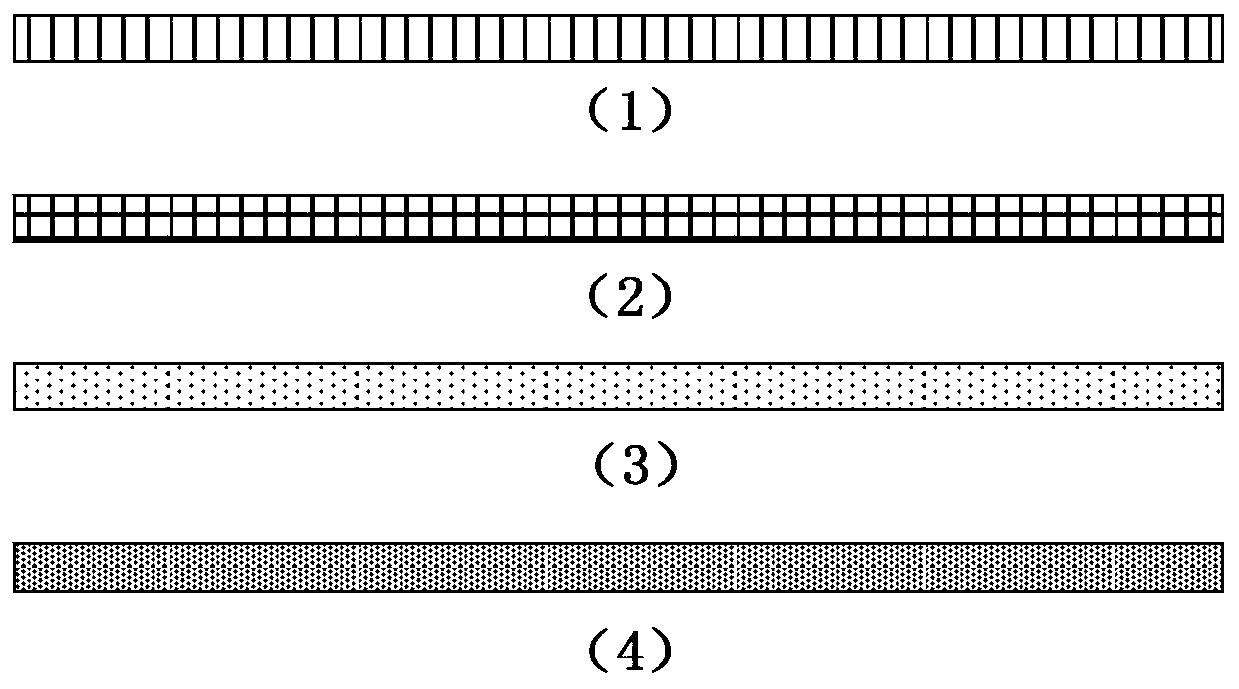

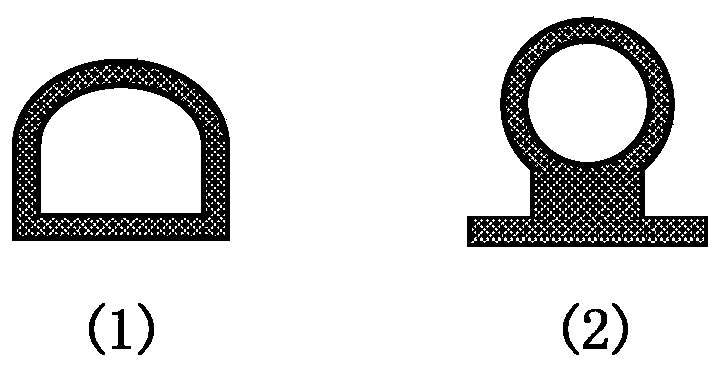

[0053] The heat insulation board is made of polycarbonate endurance board, round, and the structure is a two-layer hollow heat insulation board, such as figure 2 As shown in (2), the thickness of the skeleton solid board is 1.5mm, and the thickness of the heat insulation board is 15mm. image 3 As shown in (2), adopt hot melt adhesive, select NdFeB magnet (type N45M, density 7.5g / cm 3 ) Magnetic rod Φ5×50mm (diameter×length), heat-resistant temperature 100°C, and the sealing strip around the heat shield is arranged to fill the cavity continuously, such as Figure 4 Shown in (1). According to the density of hot and cold water in the heat storage tank, the gravity and buoyancy of the polycarbonate endurance board, and the filling amount selected in the experiment, the friction between the sealing strip and the wall surface of the heat insulation device under the action of buoyancy, gravity and magnetic force can make it in the cold and hot fluid The interface, and moves up an...

Embodiment 2

[0055] The heat insulation board is made of polycarbonate endurance board, round, and the structure is a single-layer hollow heat insulation board, such as figure 2 As shown in (1), the thickness of the skeleton solid board is 2mm, the thickness of the heat insulation board is 10mm, and the edge adopts silicone foam D-shaped sealing strip, such as image 3 As shown in (1), use hot melt adhesive, select NdFeB magnet (type N45, density 7.5g / cm 3 ) magnetic strip 100×10×2mm (length×width×thickness), heat-resistant temperature 80°C, and the cavity filling arrangement of the sealing strip around the heat shield, such as Figure 4 Shown in (2). According to the density of hot and cold water in the heat storage tank, the gravity and buoyancy of the polycarbonate endurance board, the filling amount is selected in the experiment, so that the friction between the sealing strip and the wall of the heat insulation device under the action of buoyancy, gravity and magnetic force can make ...

Embodiment 3

[0057] The heat insulation board is made of low-density silica gel foam porous board, round, with a structure such as figure 2 As shown in (3), the thickness of the heat insulation board is 10mm, and the edge adopts a silicone foam D-shaped sealing strip, such as image 3 As shown in (1), use hot melt adhesive to paste and fix the sealing strip and the heat insulation board body, and select NdFeB magnets (model N45, density 7.5g / cm 3 )Magnetic strip 50×10×2mm (length×width×thickness) with heat resistance temperature of 80°C, the cavity of the sealing strip around the heat shield is filled and arranged at intervals, such as Figure 4 Shown in (3). According to the density of hot and cold water in the heat storage tank, the gravity and buoyancy of the low-density silica gel foam porous plate, and the filling amount selected in the experiment, the friction between the sealing strip and the wall surface of the heat insulation device under the action of buoyancy, gravity, and mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com