Design method for propeller blade

A design method and technology for propellers, which are applied in the fields of calculation, image data processing, special data processing applications, etc., can solve problems such as the inability to effectively determine the overall efficiency of the propeller, and achieve the effect of shortening the design cycle and high aerodynamic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

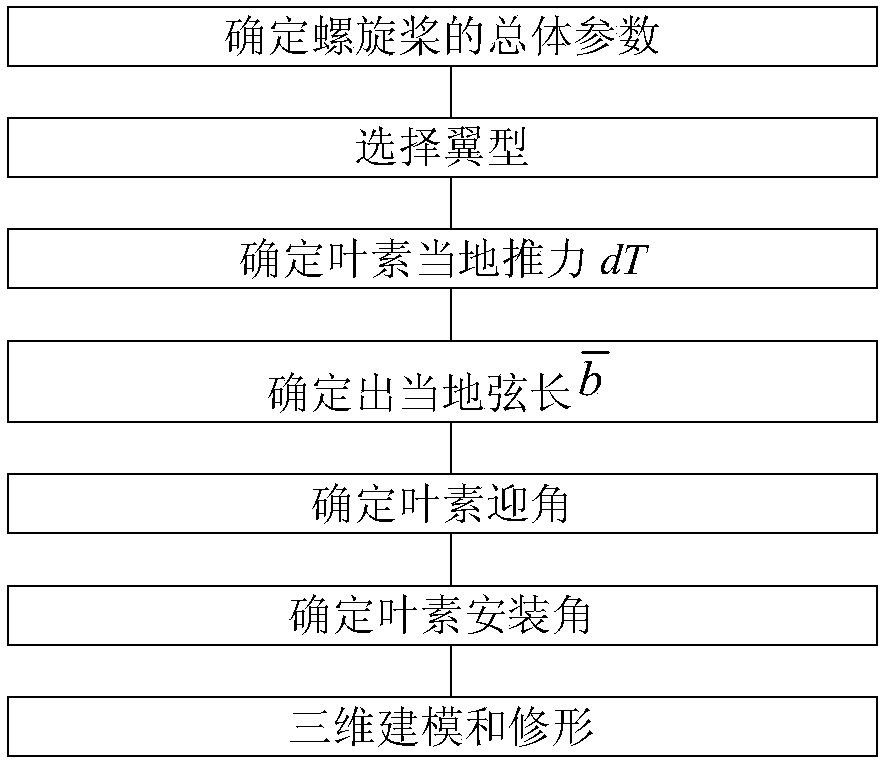

[0063] This embodiment proposes a design method of the propeller blade with the optimal load distribution. The specific process is:

[0064] Step 1. Determine the overall parameters of the propeller.

[0065] The overall parameters of the propeller determined include:

[0066] The required power is 50kW; the number of blades B=4; the diameter of the blades D=800mm; the flying height H=6000km; the flying speed V=150km / h; the propeller speed n=5500r.p.m.

[0067] Step 2. Choose the airfoil

[0068] According to the propeller's rotation speed, diameter and flight speed, according to the traditional Reynolds number, Mach number limit conditions and the best working point of the airfoil, determine the airfoil used in each section of the propeller. The propeller airfoil selected in this embodiment is an ARA-D airfoil.

[0069] Step 3. Determine the local thrust dT.

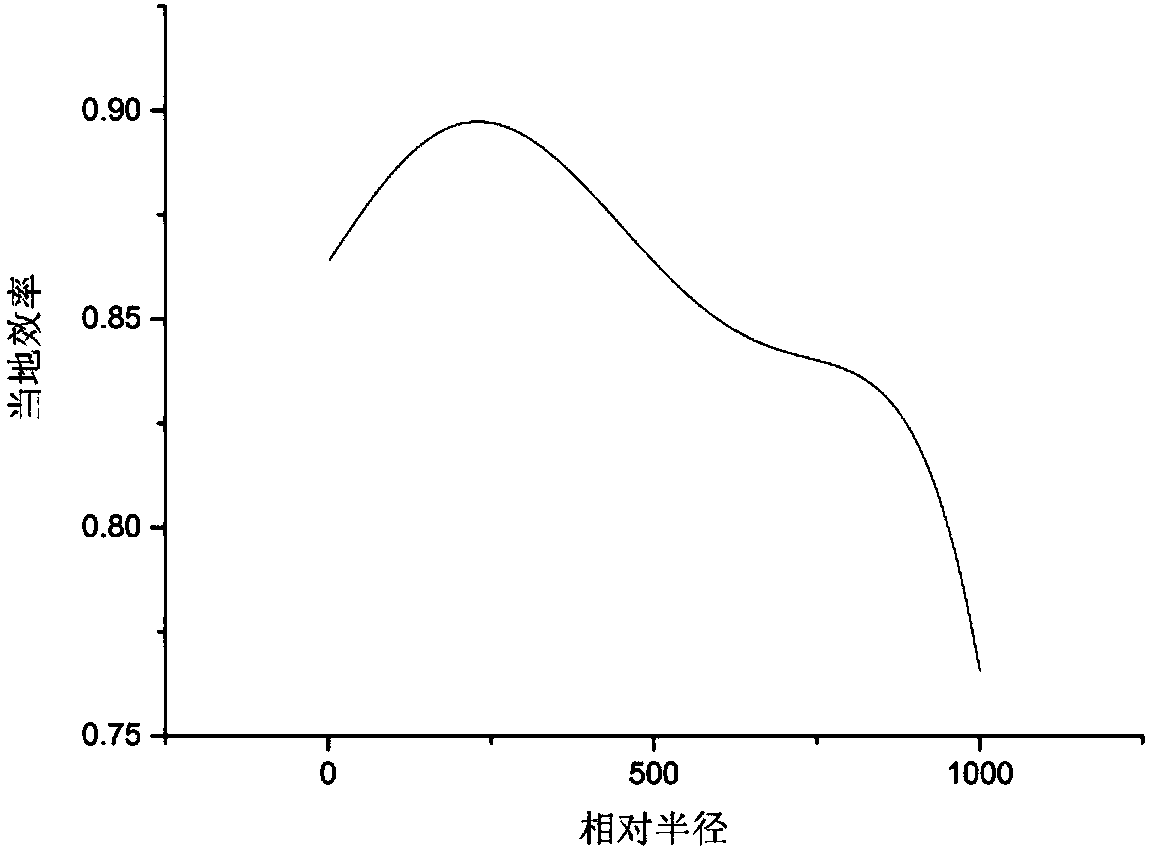

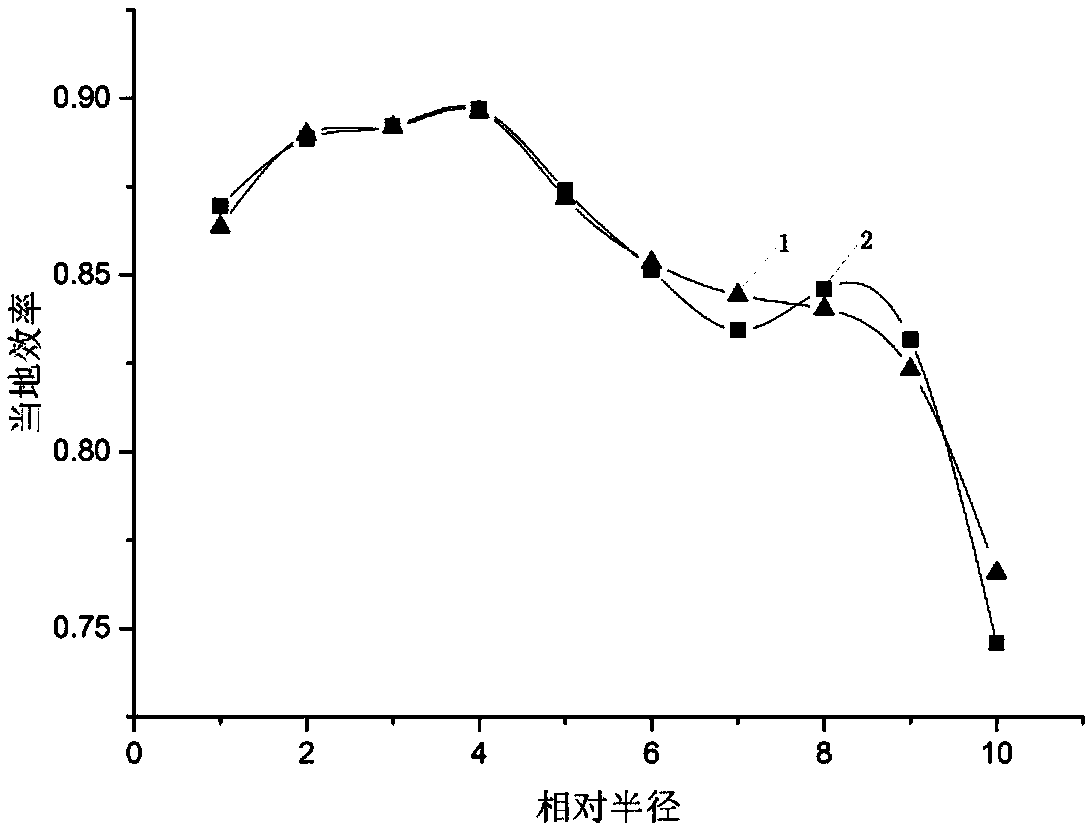

[0070] Determine the local thrust dT of the leaf element according to the local efficiency of leaf element.

[0071] The local ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com