Self-supporting optical cable sheath extrusion die

A technology of self-supporting optical cable and extrusion die, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of accelerated aging, uneven protective cover, long span distance, etc., and achieve the effect of reducing particle backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

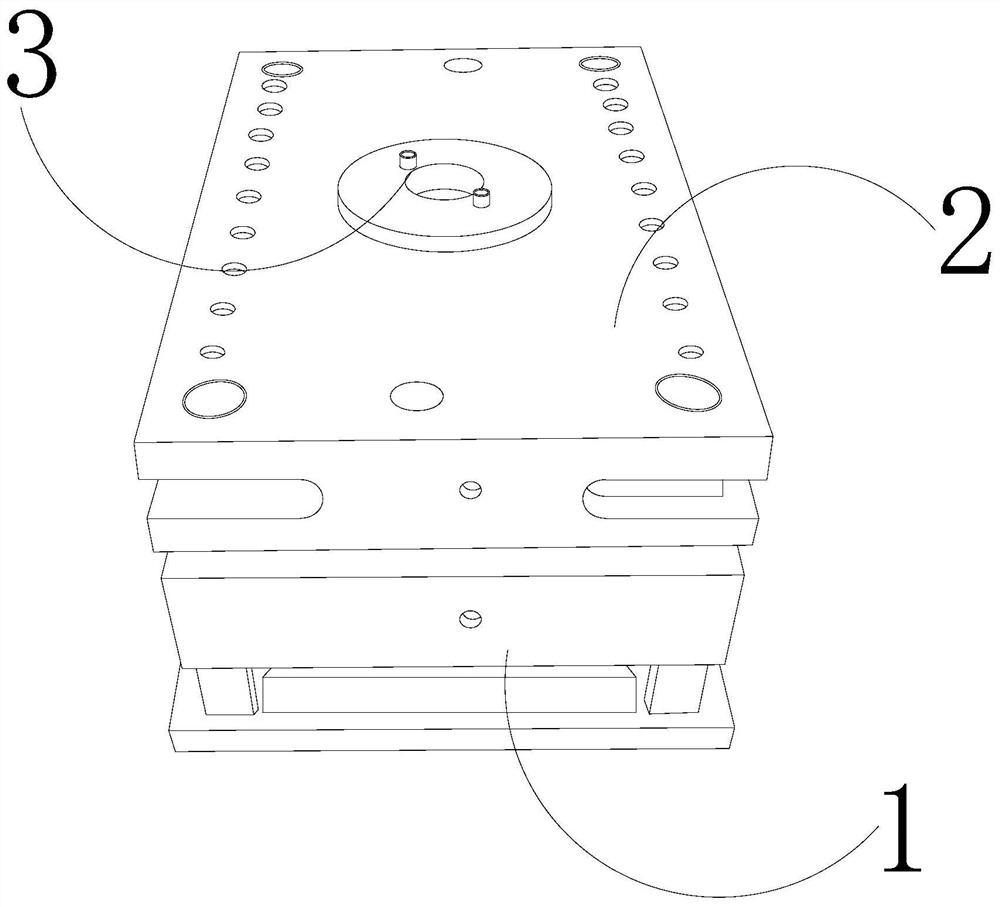

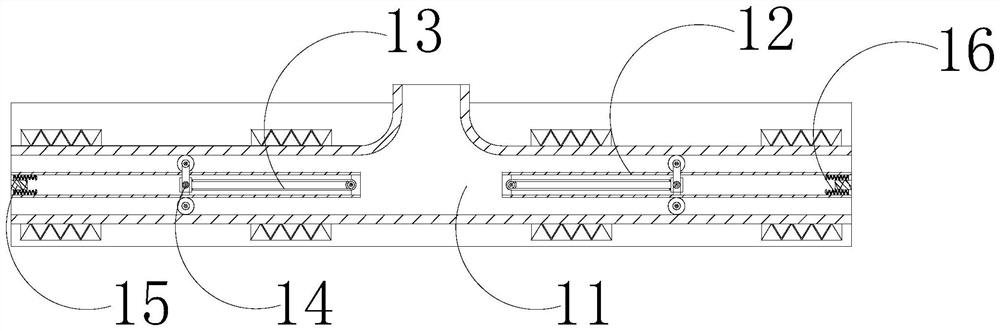

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides a self-supporting optical cable sheath extrusion die, the structure of which includes a support base 1, an upper module 2, and an injection port 3, the upper module 2 is movably matched with the top of the support base 1, and the injection port 3 runs through the upper Module 2 top center position.

[0027] The support base 1 is provided with a forming cavity 11, a hollow tube 12, a pull rod 13, a removal block 14, a magnetic block 15, and a spring 16. The forming cavity 11 is located inside the support base 1, and the hollow tube 12 is installed on the support base. 1. On both sides of the inner center, the cleaning block 14 is connected to the inner wall of the hollow tube 12 through the pull rod 13, the magnetic block 15 is fixed in the middle of the inner wall on both sides of the hollow tube 12, and the spring 16 is installed on the upper and lower sides of the magnetic block 15.

[...

Embodiment 2

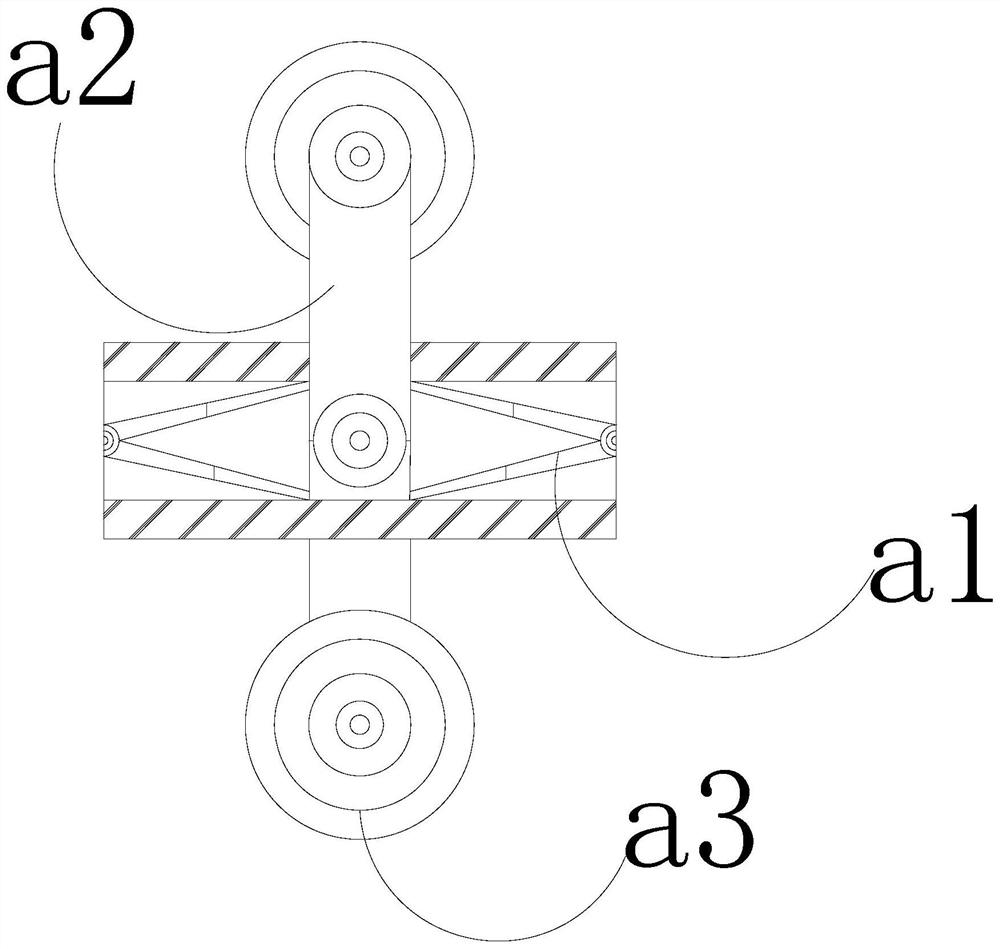

[0034] as attached Image 6 to attach Figure 7 Shown:

[0035]Wherein, the clamping block s6 is provided with a pull rope r1, an elastic block r2, a baffle r3, a chip inlet r4, and a collecting block r5, and the elastic blocks r2 are respectively installed on the left inner wall of the clamping block s6, and the baffle r3 Cooperate with the elastic block r2, the pull rope r1 is installed between the baffle plate r3 and the inner wall on the right side of the clamp block s6, the chip inlet r4 runs through the upper and lower sides of the clamp block s6, and the collection block r5 is fixed on the clamp block In the central position inside s6, the collection block r5 is trapezoidal in shape, which is conducive to increasing the collection volume inside the collection block r5, and the particles roll along the inside of the collection block r5 to reduce the backflow of particles.

[0036] Wherein, the collection block r5 is provided with an opening t1, a collection ring t2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com