A kind of toughened type PVC resin and preparation method thereof

A PVC resin and toughening technology, which is applied in the field of PVC modification, can solve the problems of reducing the amount of toughening rubber and blending links, the difficulty of uniform dispersion of toughened rubber and PVC resin, and reducing production costs, so as to reduce blending link, impact toughness improvement, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

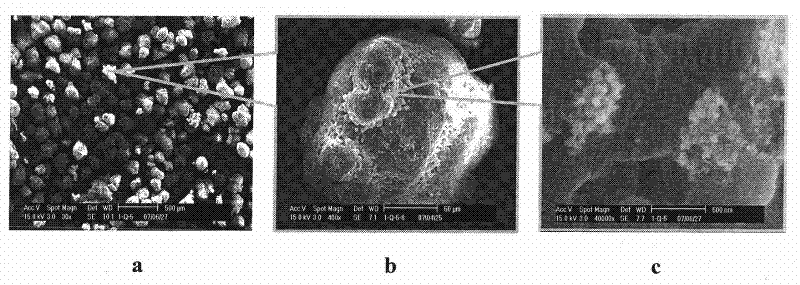

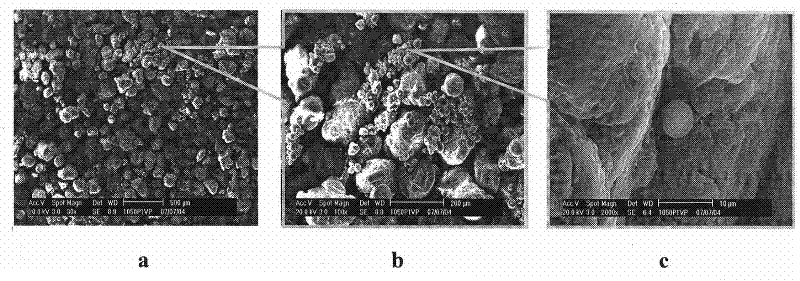

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, the present invention is described further, but does not limit the present invention thereby.

[0031] Toughened PVC resin preparation method and process formula are as follows:

[0032] Table 1 Example basic formula and performance (mass parts)

[0033]

[0034] Add required amount of PVC and deionized water into the constant temperature container, start stirring (stirring speed is 350 minutes / rotation) and heat up. When the temperature of the system reaches 80±5℃, add the toughened latex, stir evenly and slowly add the flocculant solution, stir for 2 to 5 minutes until the system flocculates uniformly and completely, stop stirring, discharge, centrifugal dehydration, and pass through the fluidized bed dryer For drying, the air inlet temperature of the dryer is set at 75-105°C.

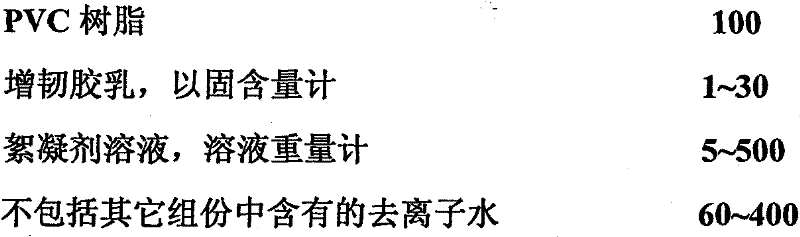

[0035] Using the aforementioned toughened PVC resin, the latex flocculation toughened resin composition prepared according to the following general f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com