Garbage treatment incineration furnace with laminar plasma as heat source

A laminar flow plasma and garbage treatment technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of poor control of turbulent plasma, insufficient automation, and unsatisfactory treatment effects, etc., to achieve ideal treatment effects, Increased range and depth of action, and ease of assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

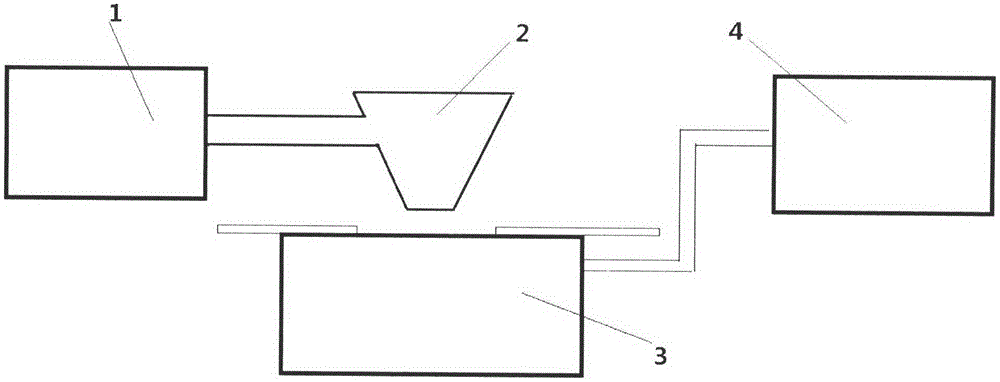

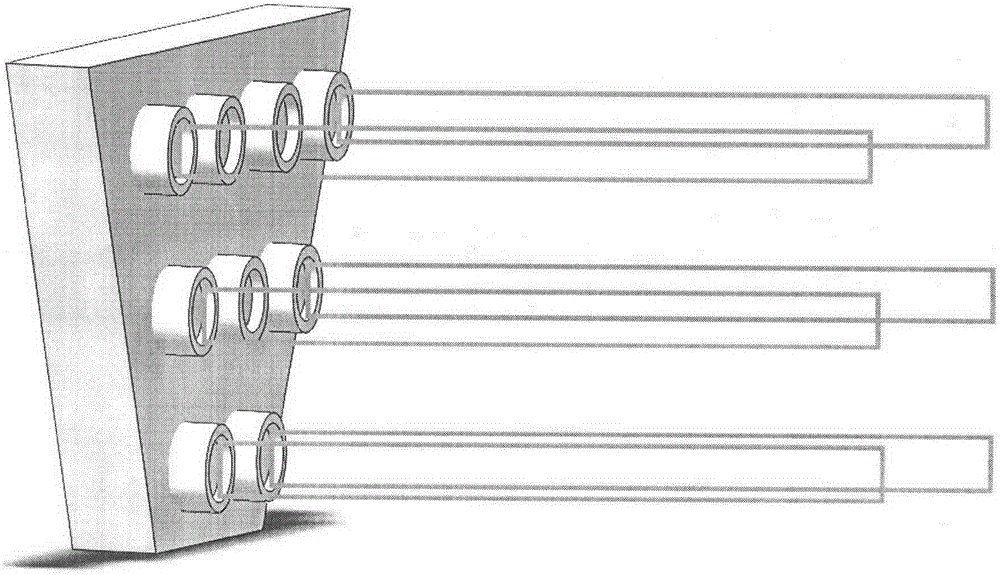

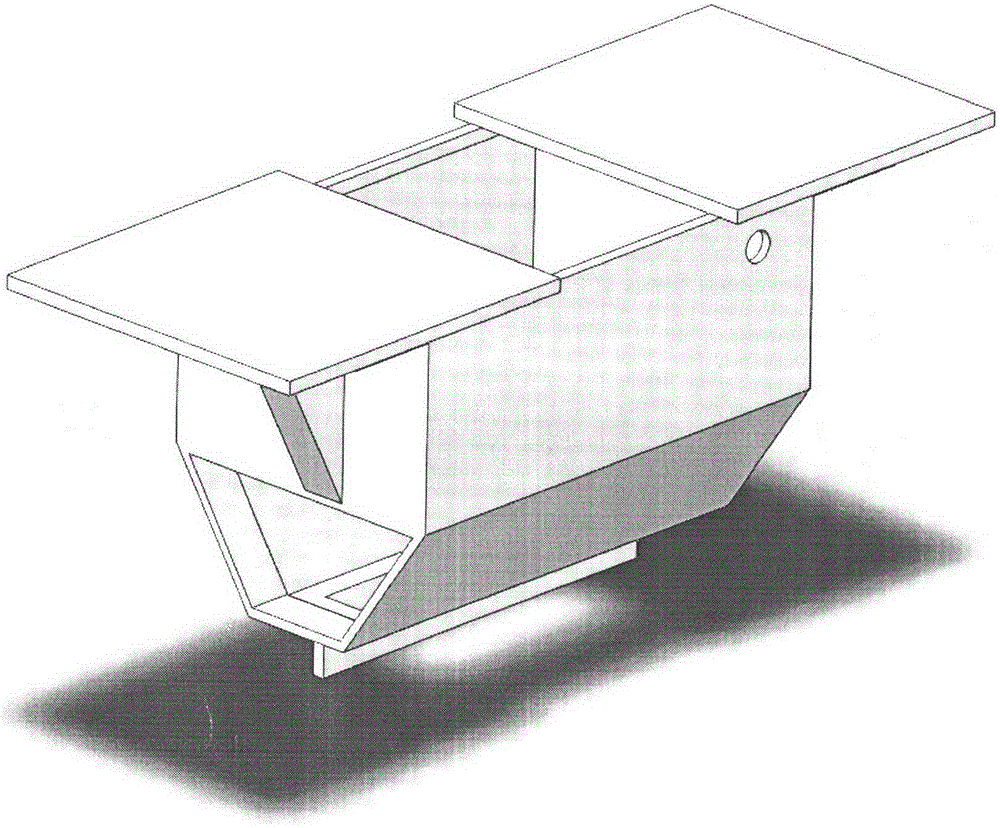

[0022] The overall schematic diagram of the work of the incinerator of the present invention is as figure 1 As shown, it includes a garbage pre-processing system 1, a hopper 2, an incinerator 3, and a waste gas treatment system 4. Laminar plasma generating electrodes such as figure 2 As shown, the electrode nozzles adopt a staggered layout. The structure of the incinerator is as image 3 As shown, the upper garbage entrance is electrified by sliding guide rails, and the waste residues below are also controlled by automatic electrical appliances. The installation of electrodes on the incinerator is as follows: Figure 4 As shown, an electrode is installed on the left and right sides of the incinerator ( Figure 4 Only the installation of one electrode is shown, and the installation of the other corresponding electrode is omitted).

[0023] The garbage pre-processing device performs simple treatment on garbage, such as garbage classification. Then the controller controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com