Sedimentation tank water treatment suction dredger

A technology of suction mud machine and pool water, which is applied in the direction of sedimentation separation, sedimentation tank, feeding/discharging device of sedimentation tank, etc. Long residence time, improved energy efficiency, smooth and non-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

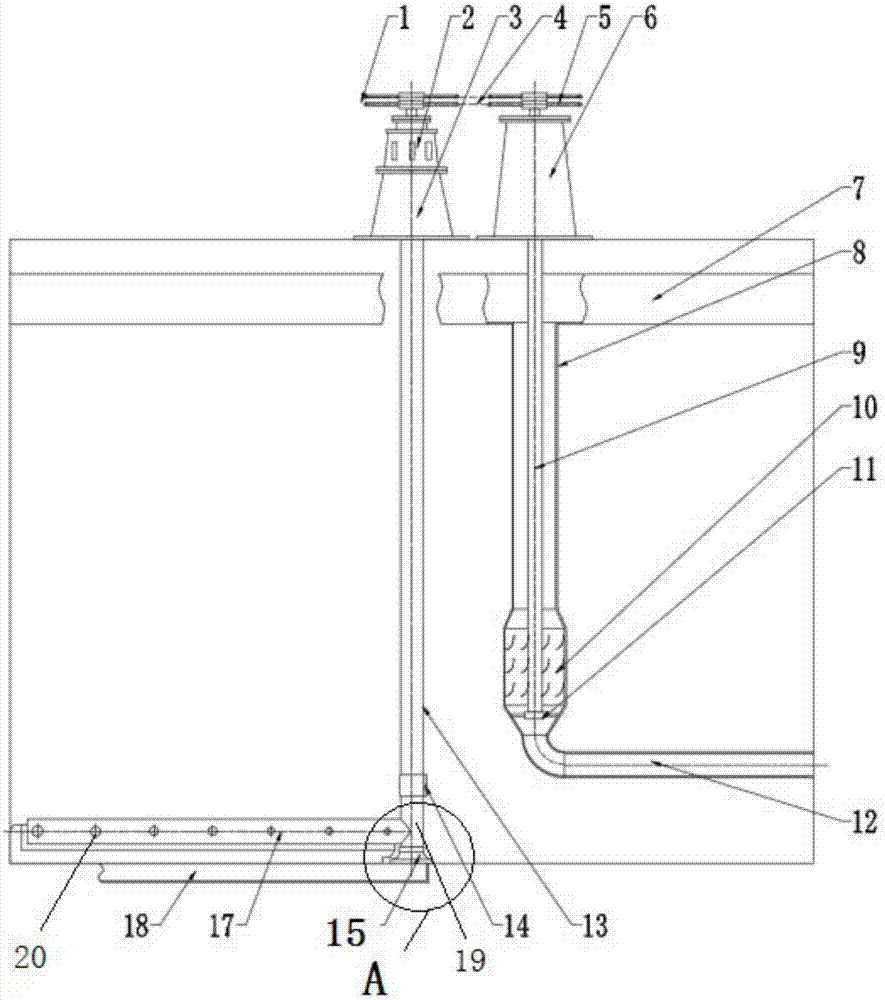

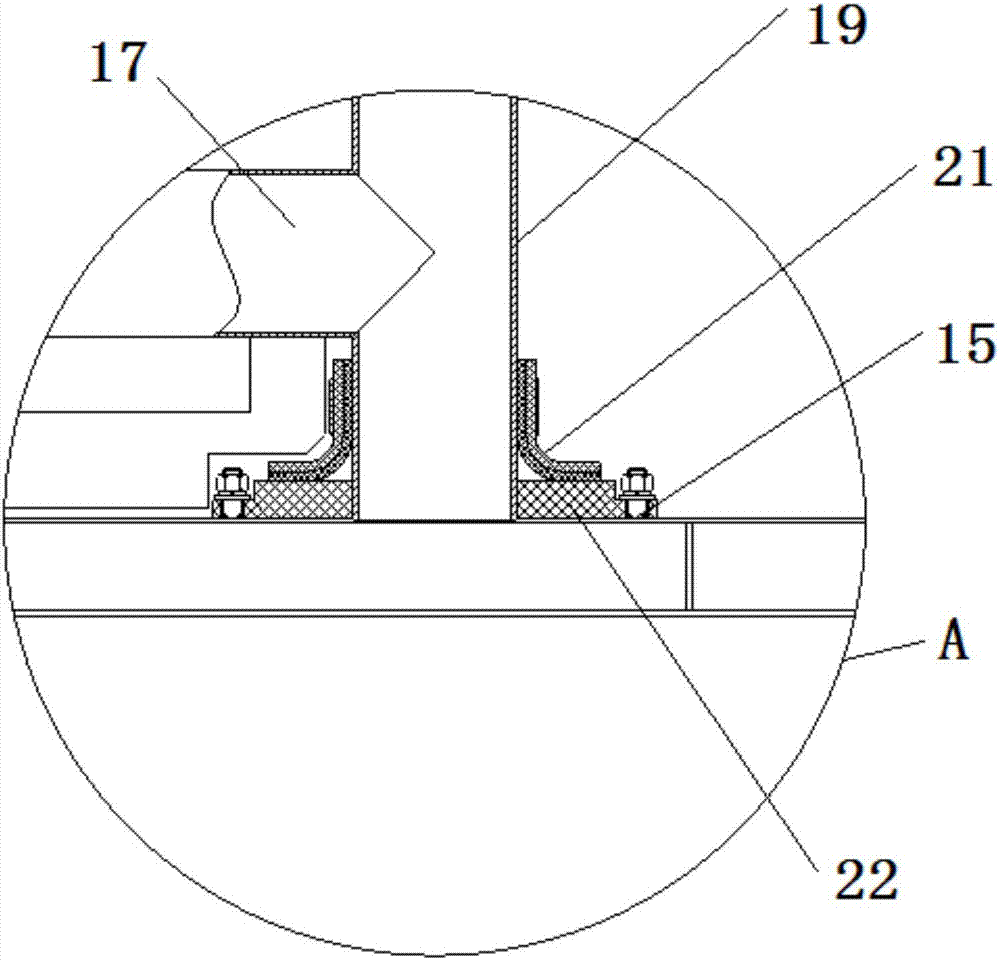

[0020] Examples, such as figure 1 , figure 2 A sedimentation tank water treatment dredger shown includes a drive mechanism, the drive mechanism is provided with a drive shaft 13 inserted into the bottom of the pool; it also includes a suction pipe 17 arranged at the bottom of the pool, the suction pipe 17 and the transmission shaft 13 A group of mud suction holes 20 are distributed on the mud suction pipe 17; the bottom of the mud suction pipe 17 is provided with a mud discharge pipe 18 communicating with it, and the diameter of the mud suction holes 20 gradually decreases from the edge of the pool to the center of the pool. The mud suction pipe 17 is a hollow steel pipe, and a rubber scraper is installed below the mud suction pipe 17 .

[0021] Transmission shaft 13 is vertically arranged, and suction pipe 17 is horizontally arranged, and one end portion of suction pipe 17 joins with the side of transmission shaft 13, and the integral body that suction pipe 17 and transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com