Novel full-hydraulic wind power system

A wind power generation system, full hydraulic technology, applied in wind power generator components, wind power generation, wind power engines, etc., can solve problems such as system frequency instability, low energy utilization rate, leakage loss, etc., to reduce volume loss and leakage loss , Avoid hydraulic oil energy loss and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

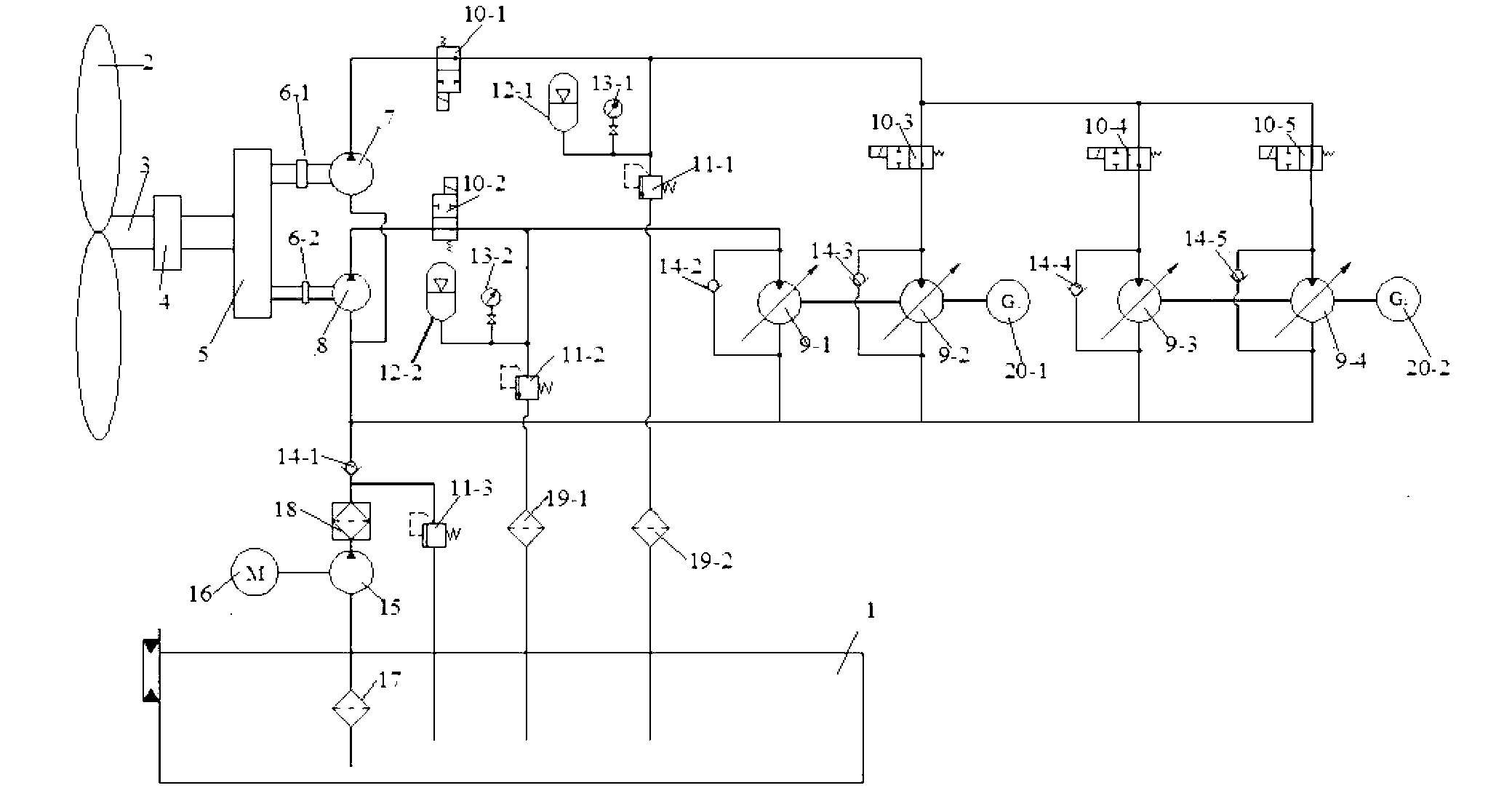

[0027] figure 1Among them, the wind rotor main shaft 3 is connected with the wind rotor 2, and the wind rotor 2 converts wind energy into the rotational mechanical energy of the wind rotor main shaft 3 under the action of the wind. 4 Through the single-input double-output gearbox 5, the torque is respectively output to the input ends of the large-displacement quantitative hydraulic pump 7 and the small-displacement quantitative hydraulic pump 8, and the large-displacement quantitative hydraulic pump 7 and the small-displacement quantitative hydraulic pump 8 are two The hydraulic pump discharges high-pressure hydraulic oil under the action of the torque of the main shaft 3 of the wind wheel, and converts the rotational...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com