Centrifugal fan and extractor hood applying centrifugal fan

A centrifugal fan and air inlet technology, which is applied in the field of centrifugal fans and range hoods, can solve problems such as increased leakage flow, easy generation of eddy currents, and decreased working ability of the impeller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

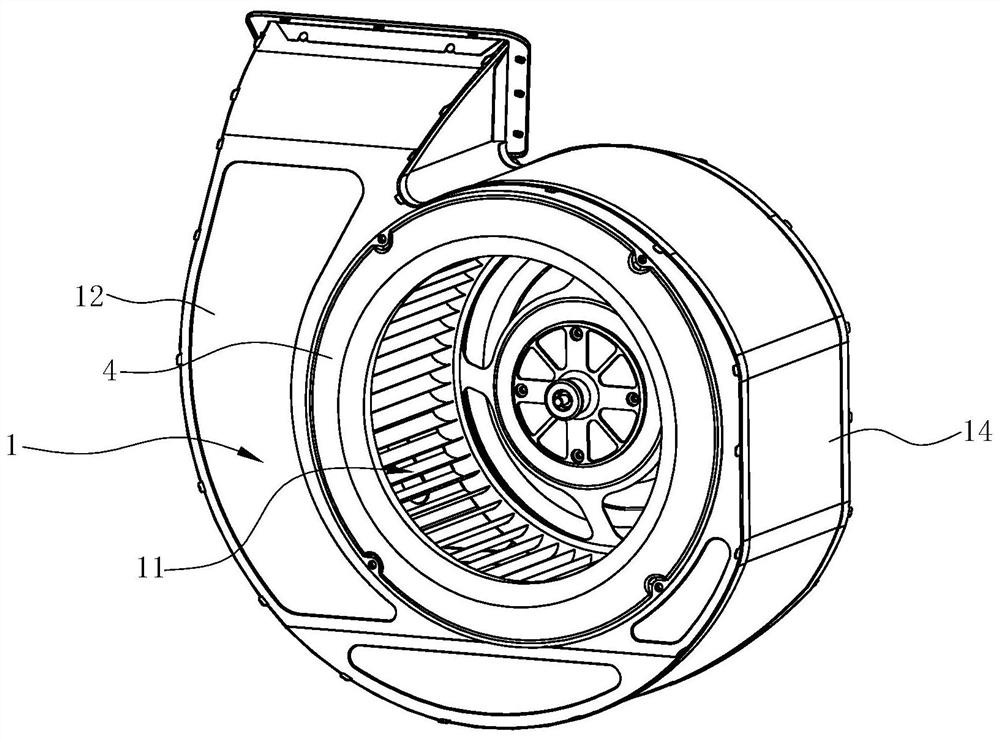

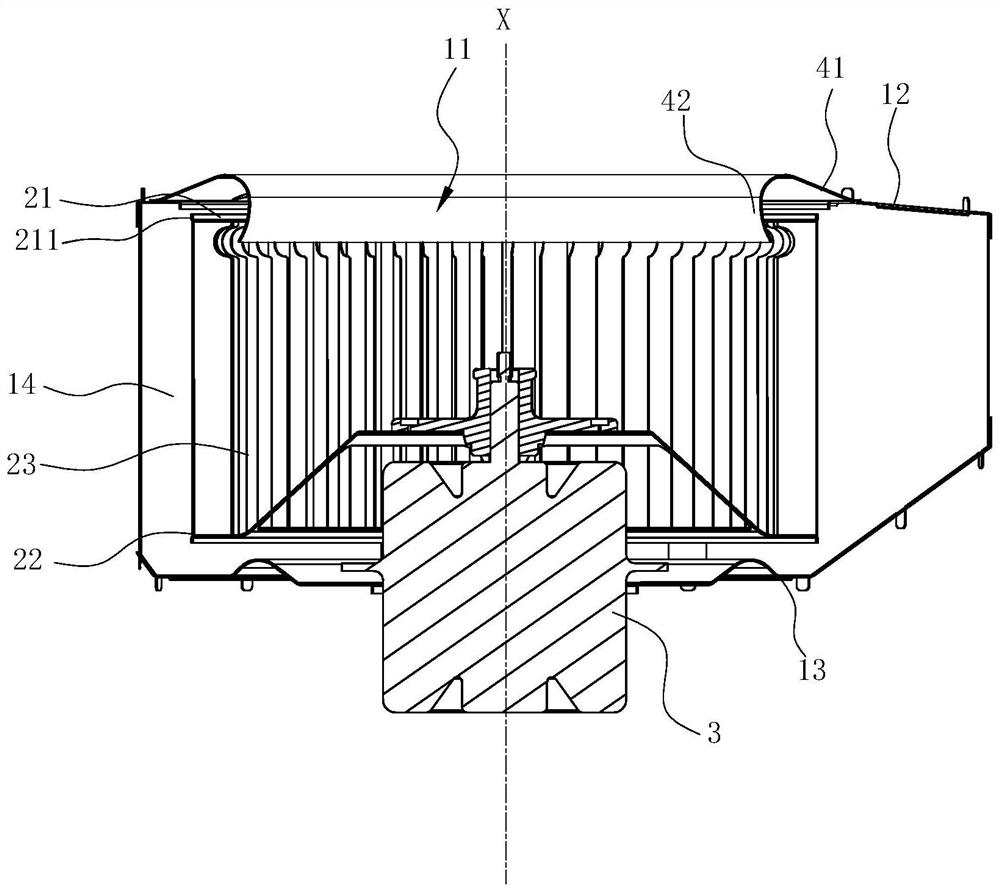

[0028] see figure 1 and figure 2 , a centrifugal fan that can be used as a power system for range hoods and other required fields. It includes a volute 1, an impeller 2 arranged in the volute 1 and a motor 3 for driving the impeller 2 to rotate. An air inlet 11 is formed on the volute 1 , and a current collector 4 is arranged at the air inlet 11 . The volute 1 includes a front cover 12 , a rear cover 13 , and an intermediate ring wall 14 arranged between the front cover 12 and the rear cover 13 . The above-mentioned air inlet 11 is opened on the front cover 12 .

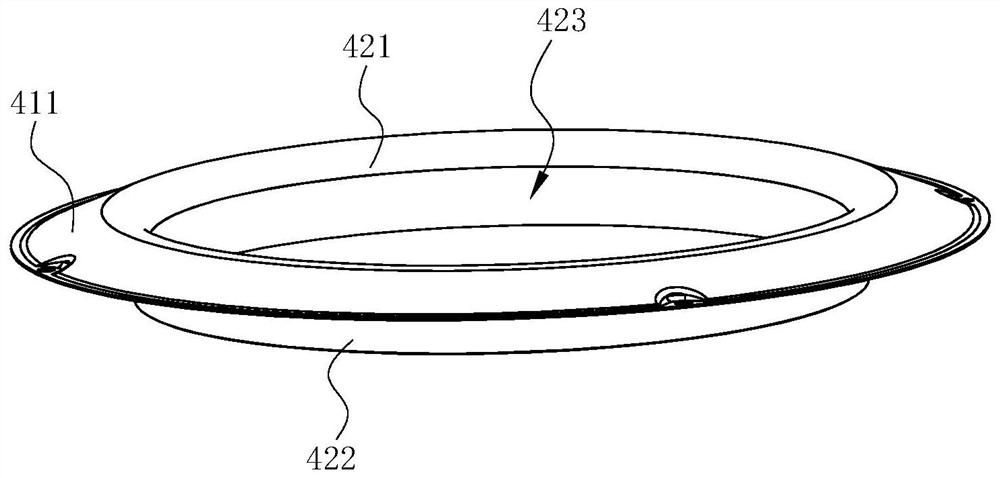

[0029] see Figure 2 ~ Figure 4 The collector 4 includes a mounting portion 41 connected to the volute 1 and a guide portion 42 for guiding the airflow. The mounting portion 41 is arranged on the outside of the volute 1 (the side away from the impeller 2), which is annular, It is connected and fixed with the outer periphery of the air inlet 11 of the volute 1. The guide part 42 is hollow cylindrical, and a vent...

Embodiment 2

[0036] see Figure 6 and Figure 7 , in this embodiment, the difference from the above-mentioned first embodiment is that a protrusion 43 is provided inside the axial guide part 422, and there are at least two protrusions 43, along which the axial guide part 422 Circumferentially spaced, preferably evenly spaced, prevents air flow from fluctuating at the tail end of the collector 4 . As a result, the resistance on the inner wall surface of the axial guide part 422 is increased, the large eddy caused by the impact of wind speed is slowed down, the sound is more comfortable when the airflow passes by, and the airflow entering along the axial guide part 422 is better. Sort out.

[0037] On the airflow path, the width (dimension in the circumferential direction) of the protrusion 43 increases gradually, thereby forming the shape of a bullet, so that the wind on the wall-adjacent surface can flow in a natural streamlined flow, avoiding loss caused by hitting the protrusion 43 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com