Mixed-flow pump impeller

A mixed-flow pump and impeller technology, applied to pumps, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as increased volume loss, serious gap cavitation, and decreased hydraulic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

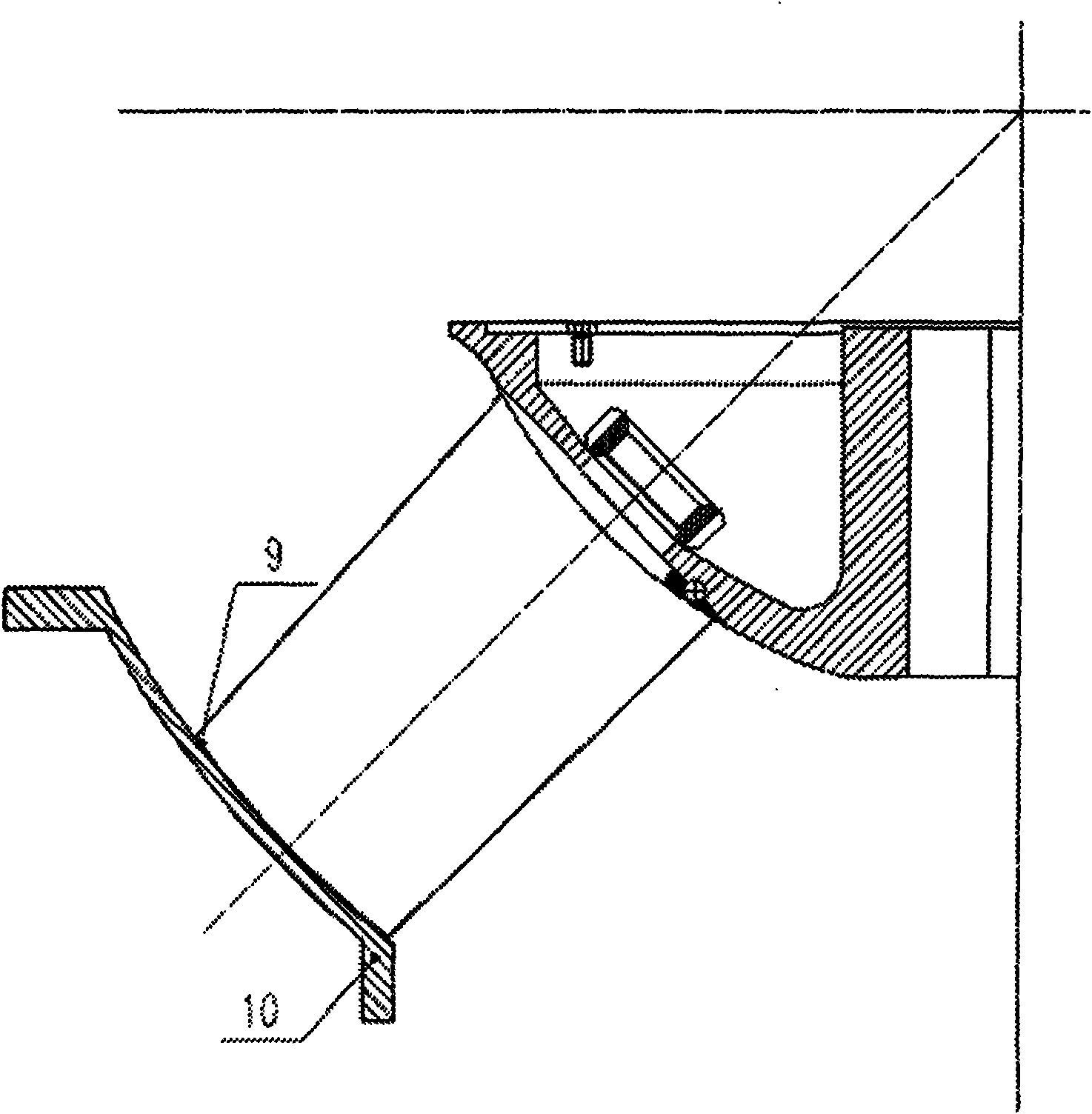

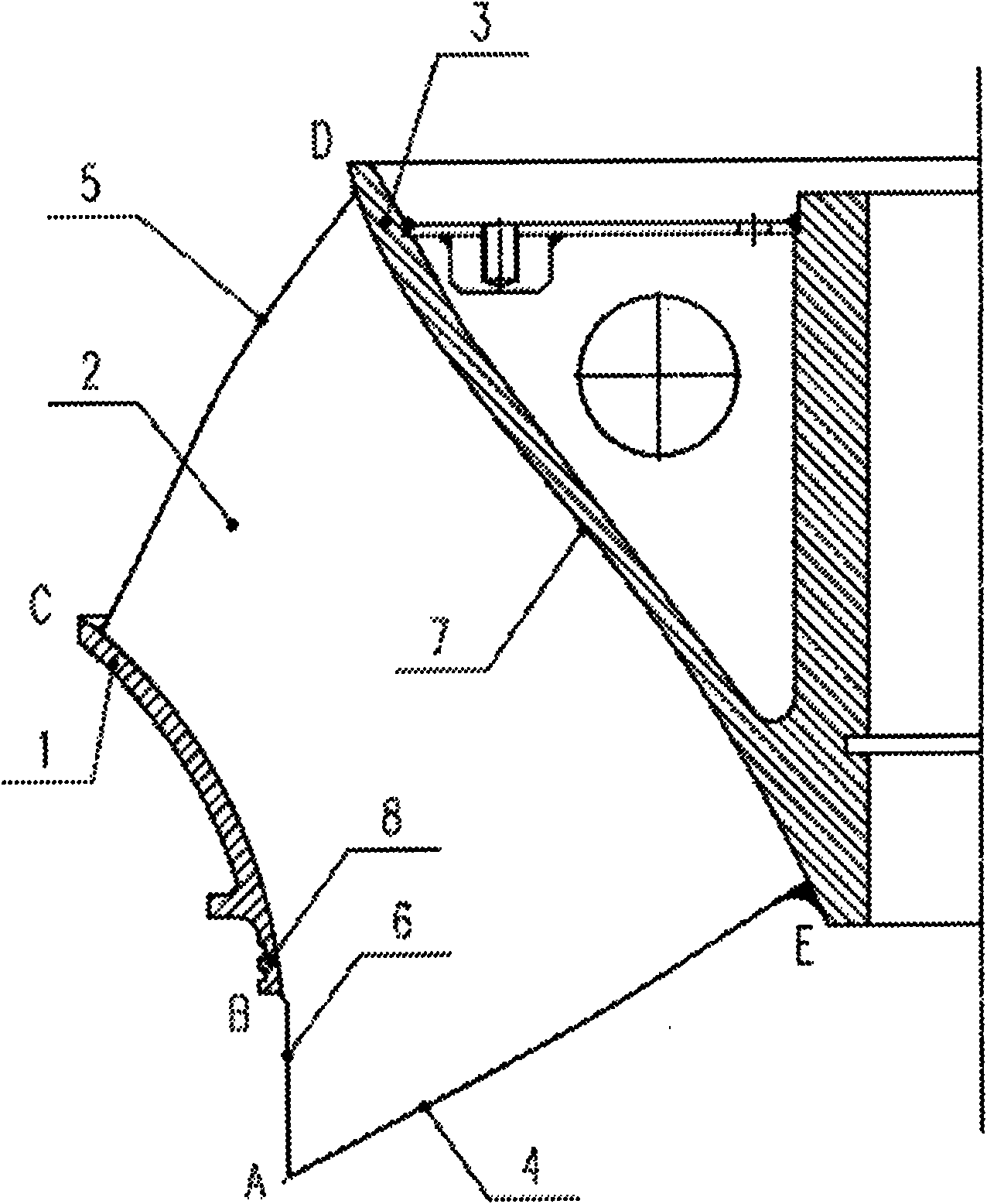

[0013] like figure 2 As shown, a mixed-flow pump impeller includes an incomplete front cover 1, a hub 3, and several blades 2 connected between the incomplete front cover 1 and the hub 3. The blades 2 have four peripheries, respectively The water inlet edge 4 of the blade, the water outlet edge 5 of the blade, the leading edge 6 of the blade on the side of the incomplete front shroud, and the trailing edge 7 of the blade on the side of the hub, the incomplete front shroud 1 and the leading edge 6 of the blade do not completely intersect, That is, the BC section of the leading edge 6 of the blade is within the annular cavity of the incomplete front shroud 1, the AB section of the leading edge 6 is exposed outside the annular cavity of the incomplete front shroud 1, and the hub 3 is completely connected to the blade trailing edge 7. Intersecting, the labyrinth groove 8 is located on the incomplete front cover plate 1, near the side of the blade water inlet 4, and the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com