Sealing ring structure for high-flow high-lift double suction pump

A sealing ring and high-lift technology, which is applied to components, pumps, and pump components of elastic fluid pumping devices, can solve the problems of reducing the actual flow rate of the pump, reducing efficiency, increasing hydraulic loss, etc., and achieve volume reduction Effects of loss, life extension, and leakage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

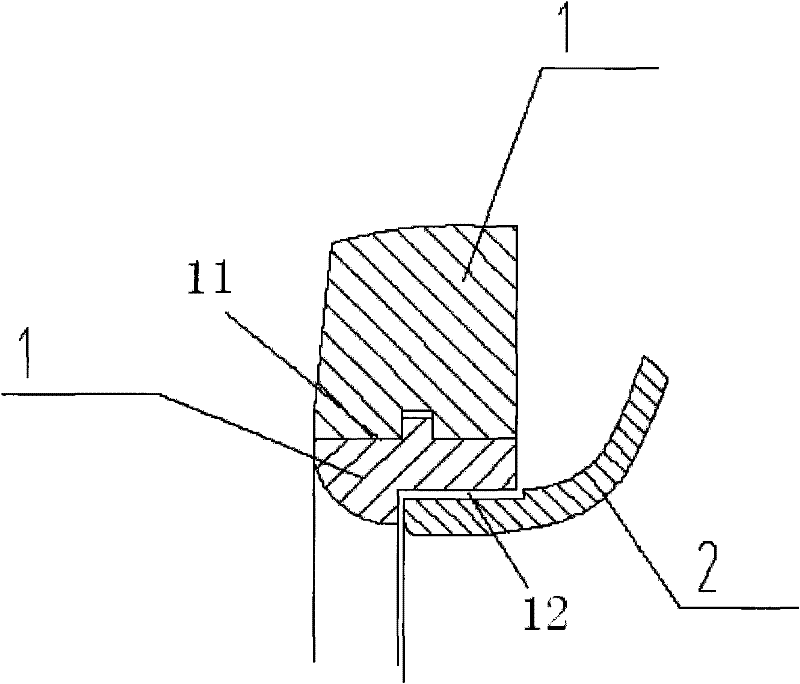

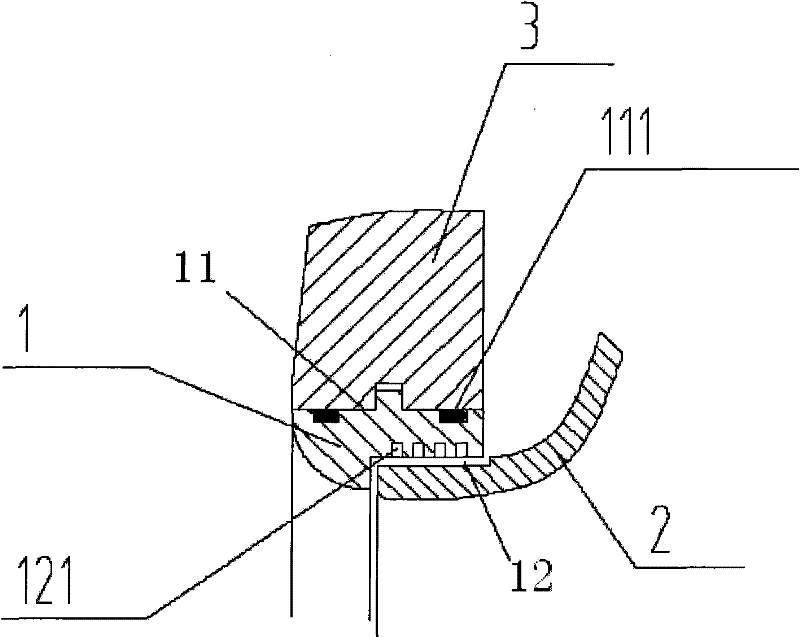

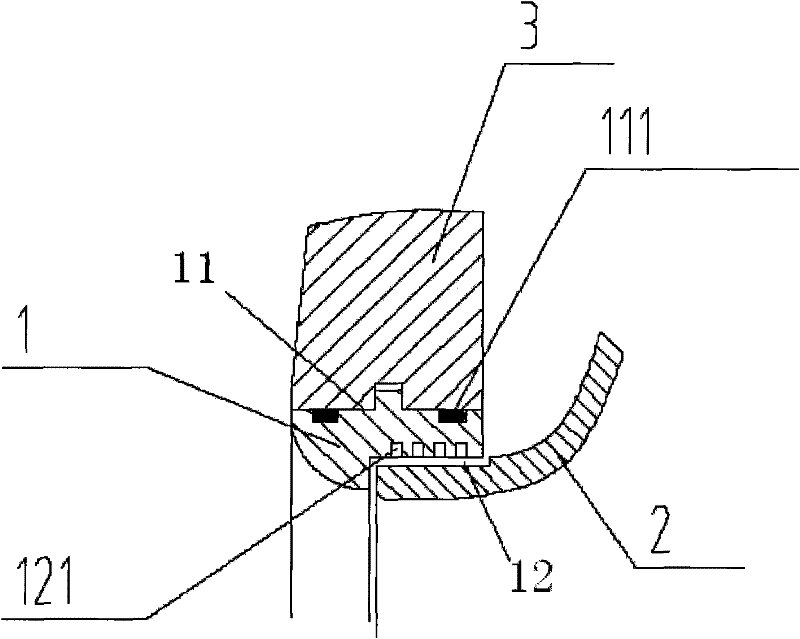

[0012] Depend on figure 2 It can be seen that the present invention includes: a body 1; the body 1 includes a sealing ring outer circle 11 and a sealing ring inner circle 12; (shown) two O-rings 111 matched with the mating surface; at least 3 labyrinth seal grooves 121 matched with the notch of the impeller 2 are also arranged on the inner circle 12 of the sealing ring;

[0013] The size of the sealing groove 121 is between 5-7mm. In the figure: housing 3.

[0014] The present invention adds two O-rings on the outer circle of the sealing ring (matching with the pump body and pump cover), and adds a labyrinth sealing groove on the inner circle of the sealing ring (matching with the impeller seam). The size of the labyrinth sealing groove (5 -7mm) and the number (≥3) are designed according to the actual situation.

[0015] The change of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com