Crushing method iron-silicon-aluminum soft magnetic powder core and preparation method thereof

An iron-silicon-aluminum and soft magnetic powder technology is applied in the field of crushing iron-silicon-aluminum soft magnetic powder core and its preparation, which can solve problems such as environmental pollution, and achieve the effects of simple preparation method, easy operation and control, and improvement of DC bias characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

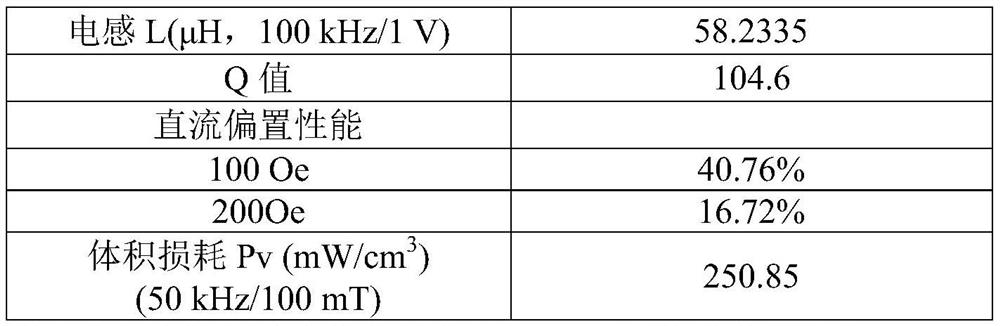

Embodiment 1

[0034] Select 1000.0g of sendust magnetic powder whose particle size is -200 mesh, the alloy composition mass percentage is Si 7.0%, Al 8.0%, and the rest is Fe; 2 Powder and 40.0g of water were stirred at room temperature for 15 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 80°C and kept stirring for 60 minutes. After the heat preservation was completed, the dried sendust The insulating powder is sieved with a 100-mesh sieve (screening out oversized particles); adding 2.0 g of binder silicone resin powder and 8.0 g of release agent zinc stearate to the sieved powder, and mixing Evenly, the magnetic powder to be formed is obtained; the uniformly mixed magnetic powder to be formed is pressed into a powder core blank with a pressing pressure of about 1600MPa, wherein the powder core blank is an annular shape with an outer diameter of 27.00mm x an inner diameter of 14.80mm x a height of 11.18mm Powder core: Using nitrogen as a protective gas, heat t...

Embodiment 2

[0038] Select the commercially available alloy with the particle size of -200 mesh as Si 9.0% and Al 5.0% by mass percentage respectively, and 1000.0g of sendust magnetic powder with the rest being Fe; SiO 2 Powder and 50.0g of water were stirred at room temperature for 25 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 90°C and kept stirring for 25 minutes. After the heat preservation was completed, the dry sendust was insulated The powder is sieved with a 100-mesh sieve; 3.0 g of binder phenolic resin and 5.0 g of release agent calcium stearate are added to the sieved powder, and mixed uniformly to obtain the magnetic powder to be formed; The pressure is about 1800MPa to press the uniformly mixed powder into a powder core blank, wherein the powder core blank is an annular powder core with an outer diameter of 27.00mm x an inner diameter of 14.80mm x a height of 11.18mm; using nitrogen as a protective gas, the pressed The powder core blanks were ...

Embodiment 3

[0043] Select the commercially available alloy with the particle size of -200 mesh as Si 8.0% and Al 6.0% by mass percentage respectively, and 1000.0g of sendust magnetic powder with the rest being Fe; SiO 2 Powder and 60.0g of water were stirred at room temperature for 35 minutes to form a uniform mixed slurry; then, the mixed slurry was heated to 100°C and kept stirring for 35 minutes. After the heat preservation was completed, the dry sendust was insulated The powder is sieved with a 100-mesh sieve; 5.0 g of binder polyamide resin powder and 7.0 g of release agent talcum powder are added to the sieved powder, and mixed uniformly to obtain the magnetic powder to be formed; The pressure is about 2000MPa to press the uniformly mixed powder into a powder core blank, wherein the powder core blank is an annular powder core with an outer diameter of 27.00mm x an inner diameter of 14.80mm x a height of 11.18mm; using nitrogen as a protective gas, the pressed The powder core blanks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com