Mineral insulated fireproof cable and preparation method thereof

A fireproof cable, mineral insulation technology, applied in insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problem of inability to produce large-length mineral insulated fireproof cables, reduce the number of cable joints, reduce construction time, and facilitate laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

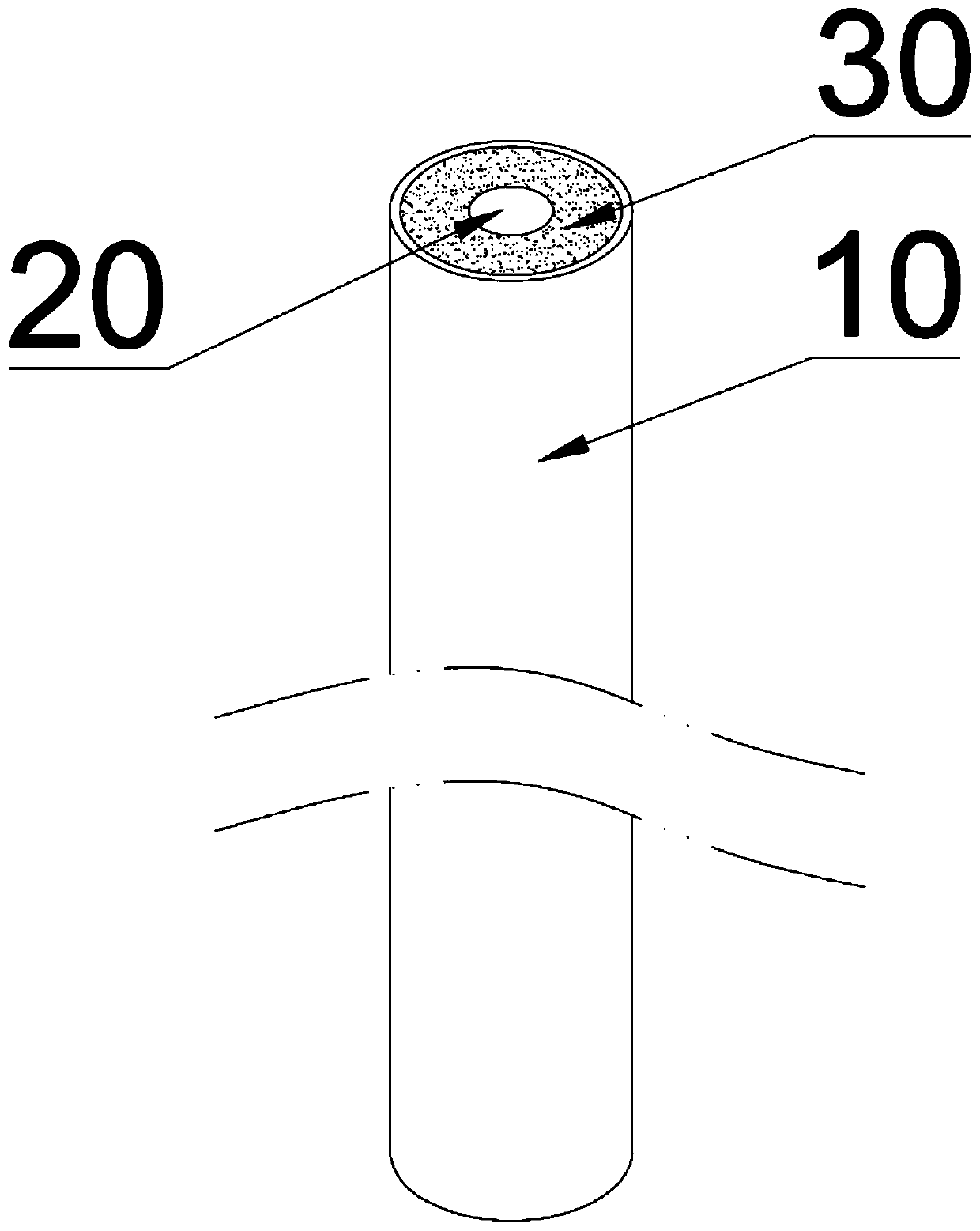

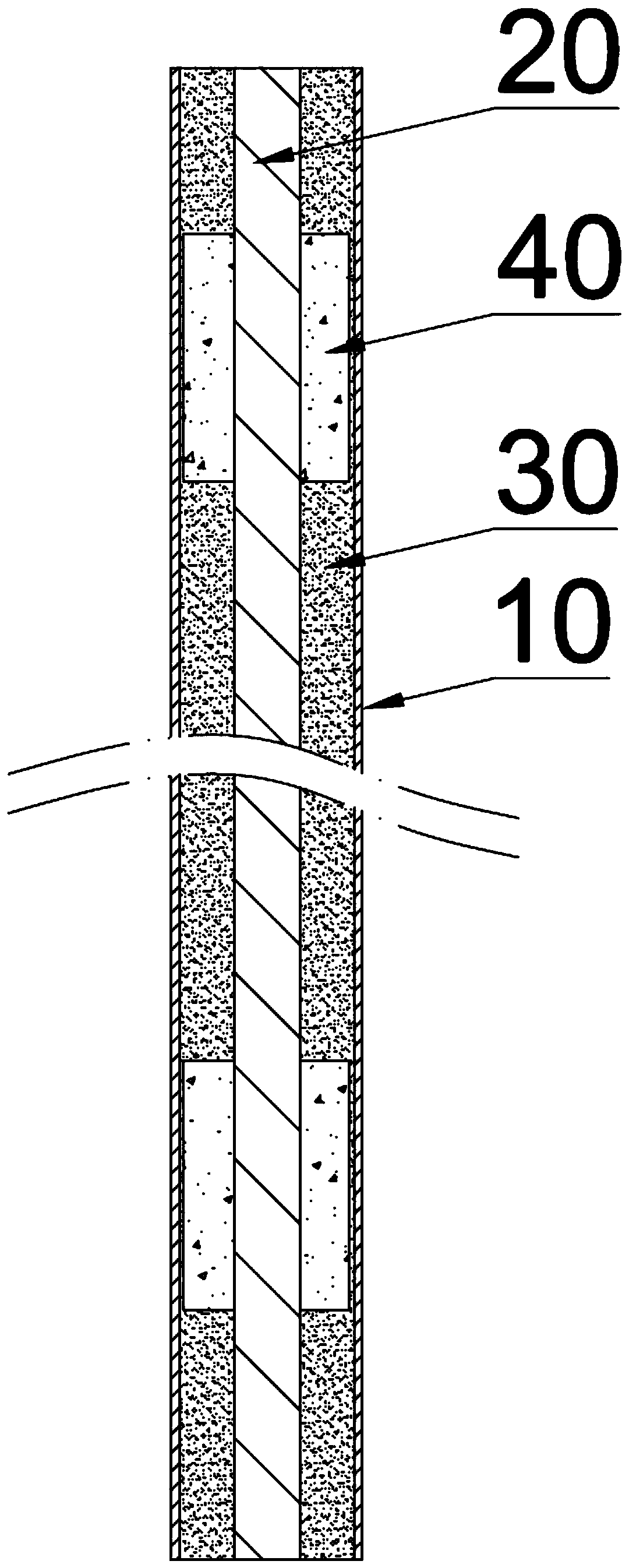

[0060] like Figure 1 to Figure 5 As shown, a preferred structure of a mineral insulated fireproof cable according to the present invention.

[0061] like figure 1 As shown, the mineral insulated fireproof cable includes a cable core 20 , a magnesium oxide filling layer and a seamless copper tube 10 arranged sequentially from the inside to the outside. Wherein, the cable core 20 is a single-strand copper conductor, such as a copper rod. The cable core 20 is coaxially arranged with the copper tube 10, and the magnesium oxide filling layer is densely filled between the cable core 20 and the copper tube 10 to realize insulation, fire resistance and high temperature resistance of the cable, and the magnesium oxide filling layer The layer belongs to the inorganic filling material, combined with the copper tube 10 and the copper rod, the mineral insulated fireproof cable is all composed of inorganic materials, so there is no problem of insulation aging, and the service life can re...

Embodiment 2

[0075] The present invention also provides a preparation method of a mineral insulated fireproof cable, which is used to make the mineral insulated fireproof cable of the above-mentioned embodiment 1 and embodiment 3, and based on the preparation method provided by the present invention, the length of the BTTZ cable is less than 100 meters To solve the problem, realize the production of large-length mineral insulated fireproof cables, and the length can be customized according to customer requirements.

[0076] Specifically, the preparation method of the mineral insulated fireproof cable includes the following steps:

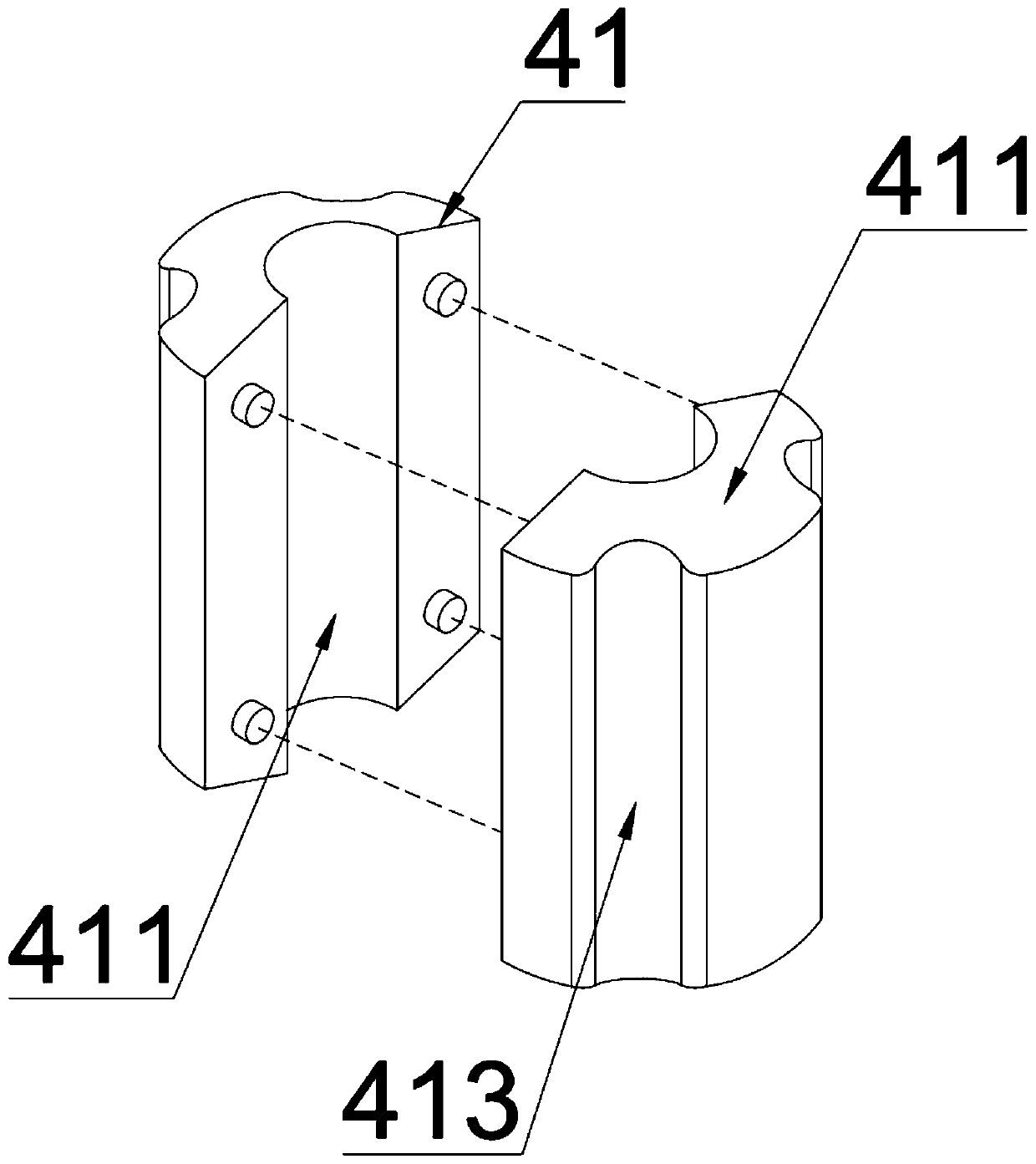

[0077] (1) Pretreatment: remove the surface impurities of the copper rod and copper strip, and dry and dehumidify the magnesium oxide powder and the magnesium oxide column; the magnesium oxide column is assembled by two mutually symmetrical half cylinders .

[0078] (2) Copper pipe shaping: send the copper strip into the shaping mold, roll the copper strip into...

example 1

[0112] In the example 1 of the present invention, a kind of production method of BTTZ fireproof cable comprises the following steps:

[0113] (1) Pretreatment: remove surface impurities of copper rod and copper strip, and dry and dehumidify magnesium oxide powder and magnesium oxide column.

[0114] (2) Copper pipe shaping: send the copper strip into the shaping mold, roll the copper strip into a tubular shape to obtain a tubular copper strip, then straighten the copper rod and penetrate into the middle of the tubular copper strip, and make the copper rod and the copper rod through the fixed core mold Copper belt concentric;

[0115] Wherein, the setting mold and the core fixing mold are arranged obliquely, so that the tubular copper strip and the copper rod are inclined, and the included angle between them and the horizontal plane is the same as 40°.

[0116] (3) Magnesium oxide filling: Fill the magnesium oxide powder into the middle of the copper rod and the tubular copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com