Aerodynamic radial foil bearing with forward and reverse rotation directions and dovetail-shaped structure

An air dynamic pressure, foil bearing technology, applied in the direction of rotating motion bearings, sliding contact bearings, bearings, etc., can solve the problems of rotation assembly error, shaft failure stability, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

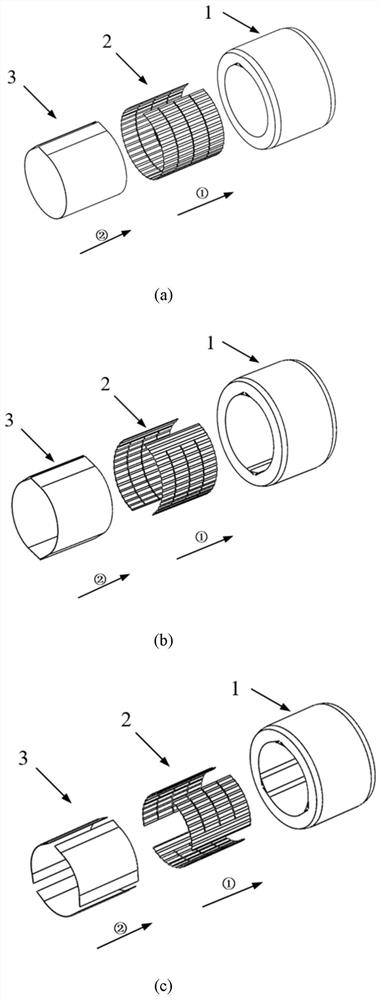

[0033] An elliptical tile air dynamic pressure radial foil bearing with positive and negative rotation directions, comprising a bearing sleeve 1; a corrugated foil 2; a top foil 3;

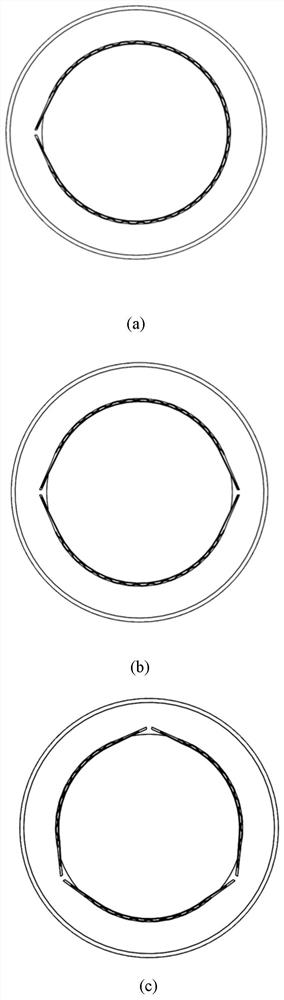

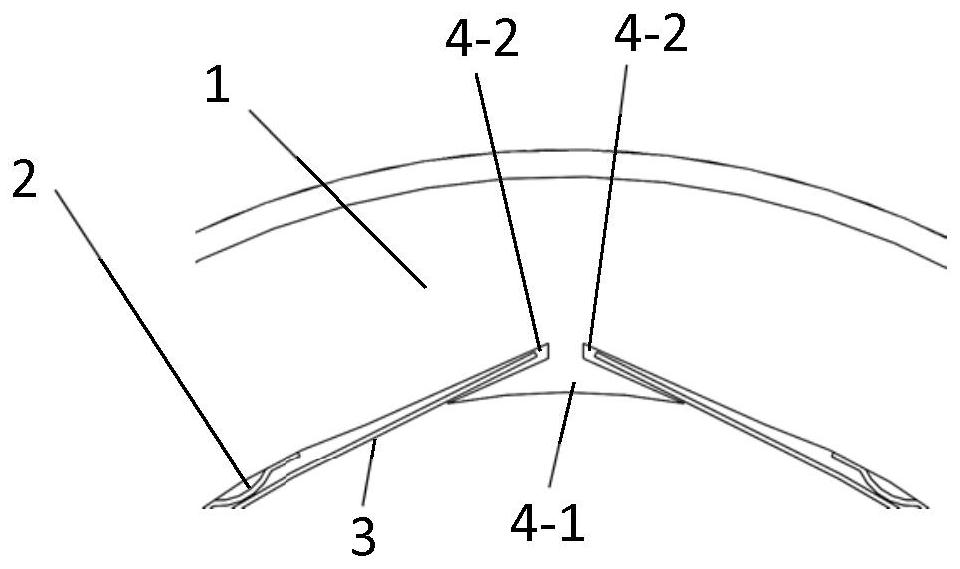

[0034]The bearing sleeve 1 is a hollow cylinder used to fix the corrugated foil 2 and the top foil 3, and one or two or three dovetail structures 4 with an angle of 120 degrees to each other can be opened on the bearing sleeve 1 (When there is only one dovetail groove, the top foil 3 and the corrugated foil 2 are circular, as shown in the attached Figure 6 (a), with Figure 7 As shown in (a), when the relative dovetail groove 4 is used, the top foil 3 and the corrugated foil 2 are double-lobe separated, as shown in the attached Figure 6 (b), with Figure 7 As shown in (b), the top foil 3 and the corrugated foil 2 used when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com