Pressure regulating valve group of pressure regulating cone valve

A technology of pressure regulating valve group and cone valve, which is applied in the field of pressure regulating valve group, can solve the problems of gas personal safety hazards, gas leakage, gas leakage, etc., achieve obvious economic and social benefits, reduce direct scouring wear, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with embodiment with accompanying drawing:

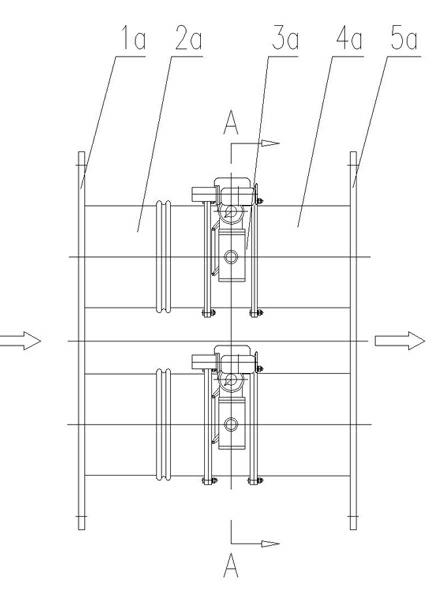

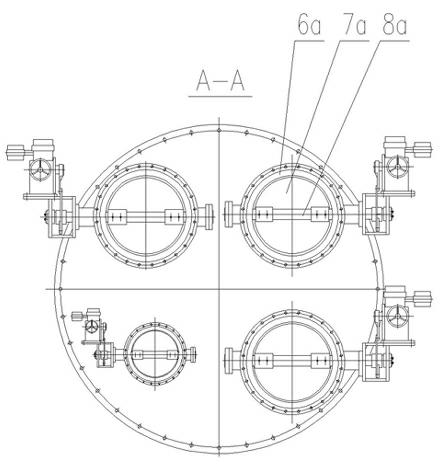

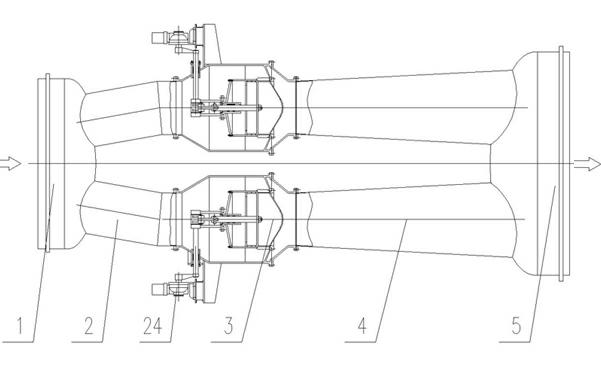

[0019] Such as image 3 As shown, the pressure regulating cone valve pressure regulating valve group of the present invention includes a front pipe 1, a front guide pipe 2, a pressure regulating cone valve 3, a rear guide cone pipe 4, and a rear pipe 5, wherein at least two front pipes are connected to the front pipe 1. The guide pipe 2 is evenly distributed along the center of the front pipe 1, and the other end of each front guide pipe 2 is connected to a pressure-regulating cone valve 3 through a flange connection. The other end of each pressure-regulating cone valve 3 A rear guide tapered pipe 4 is respectively connected by a flange connection type, and all rear guide tapered pipes 4 are connected with the rear pipe 5 and are evenly distributed along the equidistant circumference of the pipe center of the rear pipe 5 . The number of the front guide pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com