Low frequency calibration vibrating table

A shaking table, low frequency technology, applied in the direction of instruments, etc., can solve the problem that the calibration shaking table cannot meet the calibration of low frequency sensors, and achieve the effects of stable vibration, wide vibration frequency range and small harmonic distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

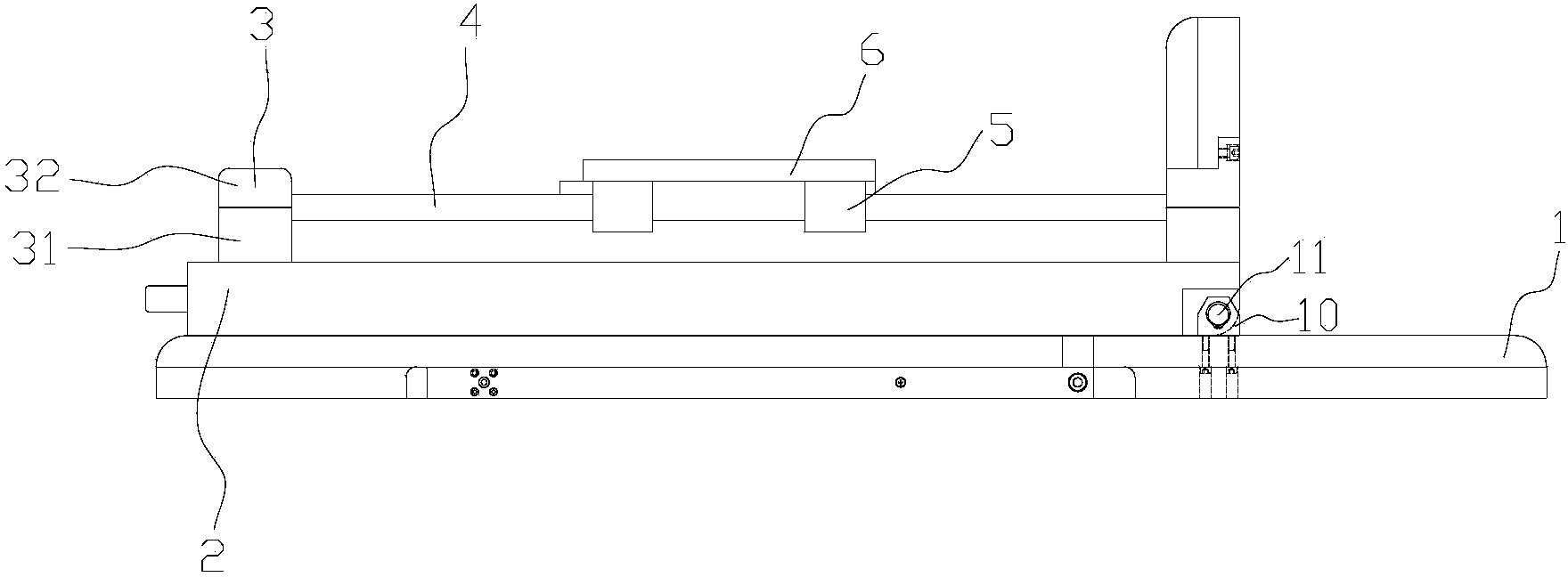

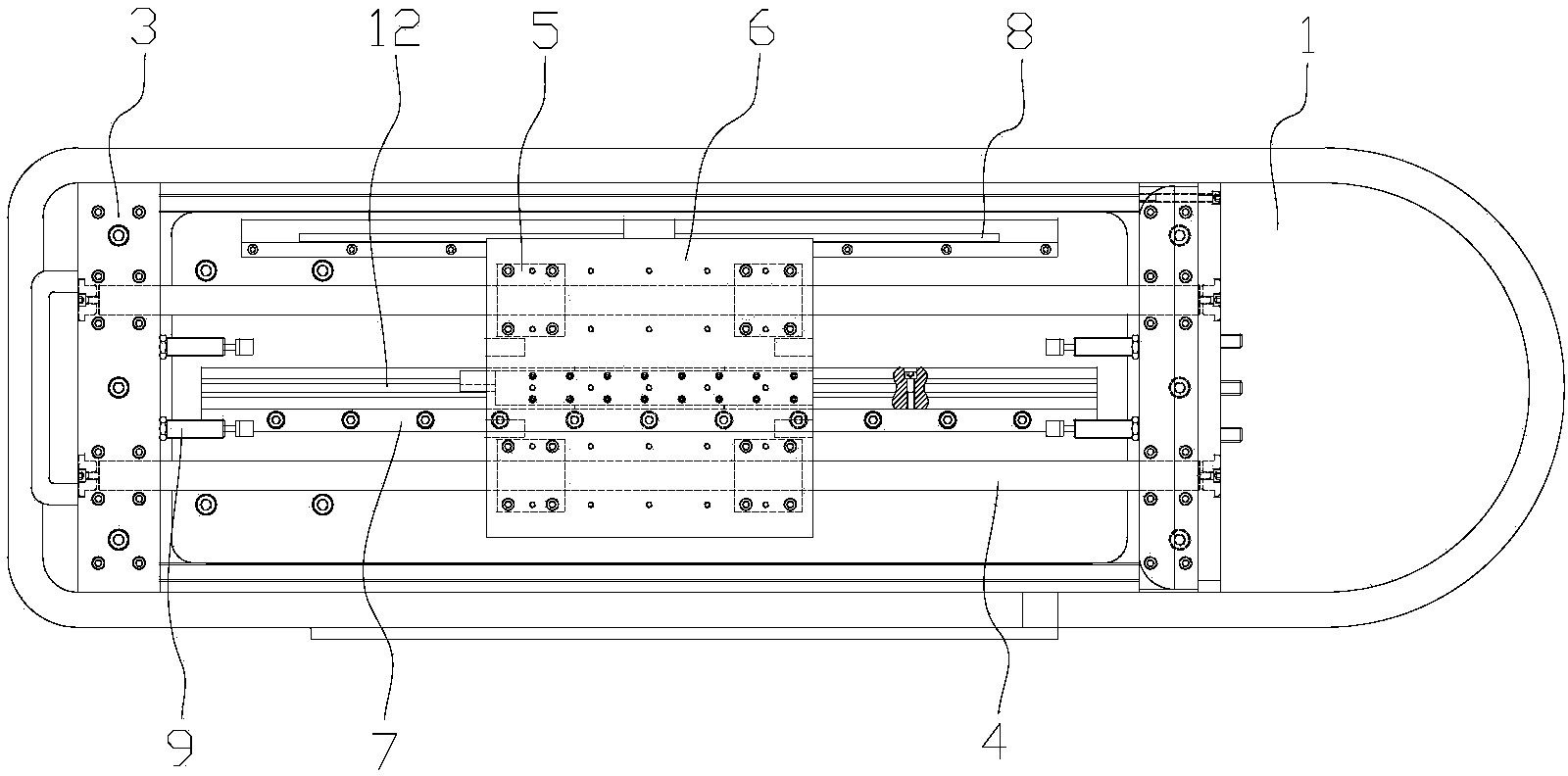

[0021] see Figure 1-2 As shown, a low-frequency calibration vibrating table includes a base 1 and a mounting base 2 fixed on the base 1. Two ends of the mounting base 2 are respectively fixed with a support 3 along its width direction. Between the two support 3 A pair of guide shafts 4 are fixed symmetrically and at intervals, each guide shaft 4 is provided with two air bearings 5, a total of four air bearings 5, the air bearings 5 choose a square structure for easy assembly, and the working platform 6 is fixed on the Four air bearings 5, and each corner of the working platform 6 is fixedly connected with one air bearing 5, so as to ensure the stability of the working platform 6. A linear motor 7 is fixed between a pair of guide shafts 4 on the mounting base 2 , the linear motor 7 is fixedly connected to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com