Hydro-pneumatic spring device with inerter and damper connected in parallel

A technology for oil-gas springs and inertial containers, applied in springs, springs/shock absorbers, shock absorbers, etc., can solve the problems of backlash bearing capacity, difficult processing and high cost of mechanical inertial containers, and improve driving comfort and performance. Handling stability, ease of manufacture and application, effect of damping high frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

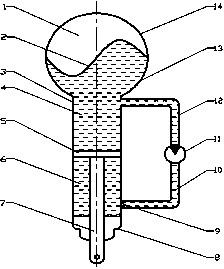

[0019] figure 1 Shown is an oil-pneumatic spring device in which an inerter and a damper are connected in parallel, including a gas spring working part, an inerter working part, a damping working part and an outer protection part. The working part of the gas spring includes an air chamber 1, an upper hemispherical chamber 14, a lower hemispherical chamber 13, and a rubber oil-gas diaphragm 2. The rubber oil-gas diaphragm 2 divides the gas chamber 1 into an upper hemispherical chamber 14 and a lower hemispherical chamber 13, and the upper hemispherical chamber 14 is filled with The elastic medium is nitrogen, and the lower hemispherical chamber 13 is filled with force transmission medium oil. The air chamber 1 is fixed on the upper end of the hydraulic cylinder 3; the working part of the inerter includes a hydraulic motor 11, a high-pressure hose A12 and a high-pressure hose B10. The hose A12 and the high-pressure hose B10 are connected to the small holes on the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com