A stirling engine assembly

A Stirling engine, engine technology, applied in the direction of machine/engine, hot gas variable capacity engine device, mechanical equipment, etc., can solve problems such as instability, and achieve the effect of eliminating contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

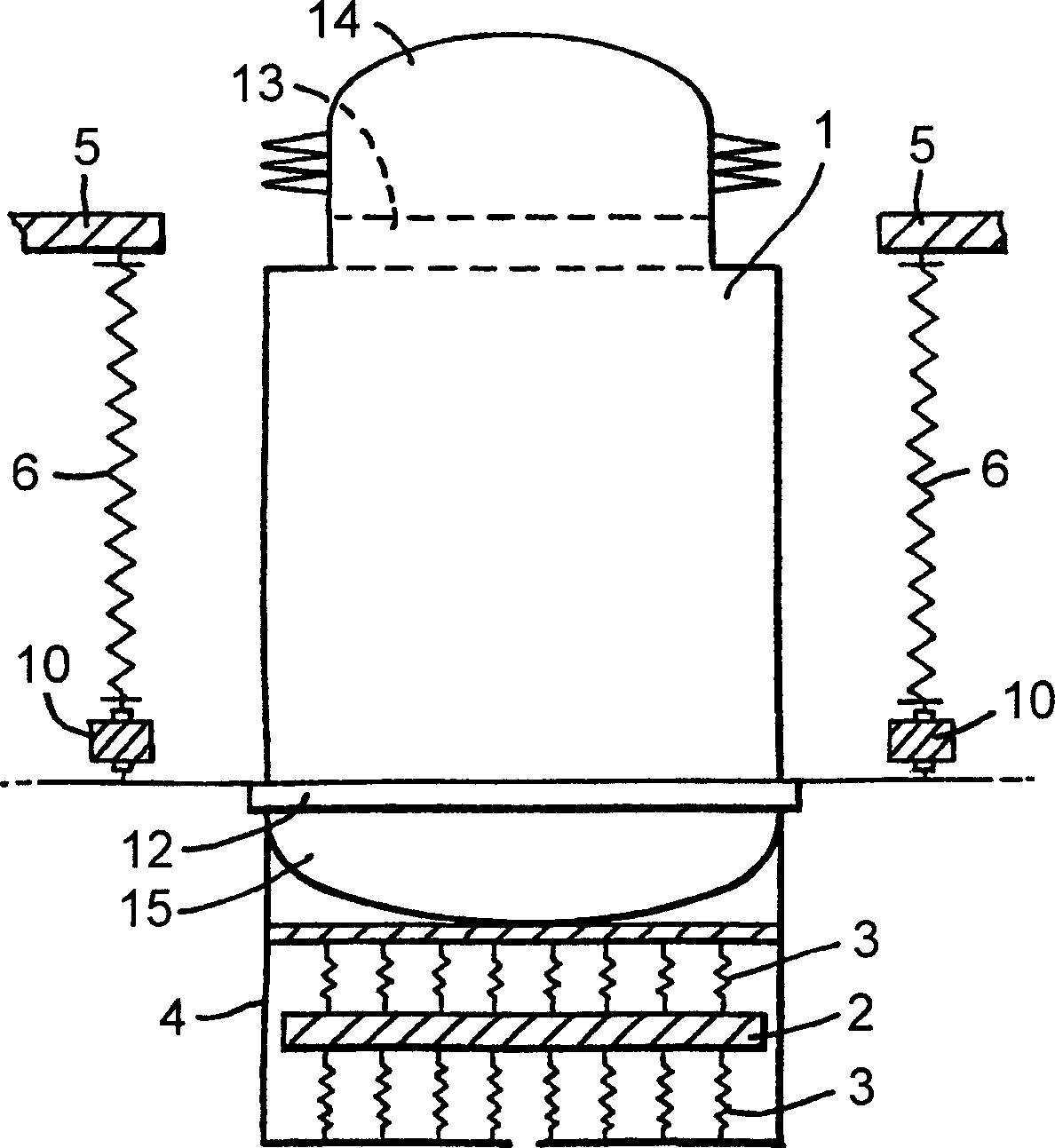

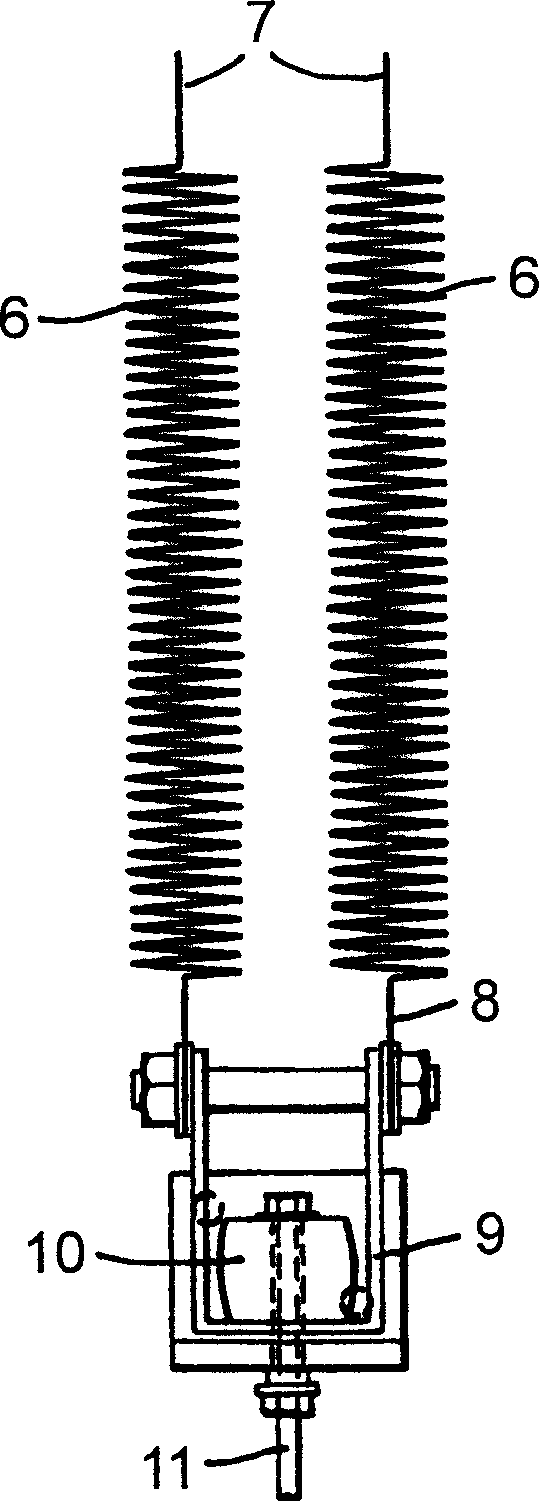

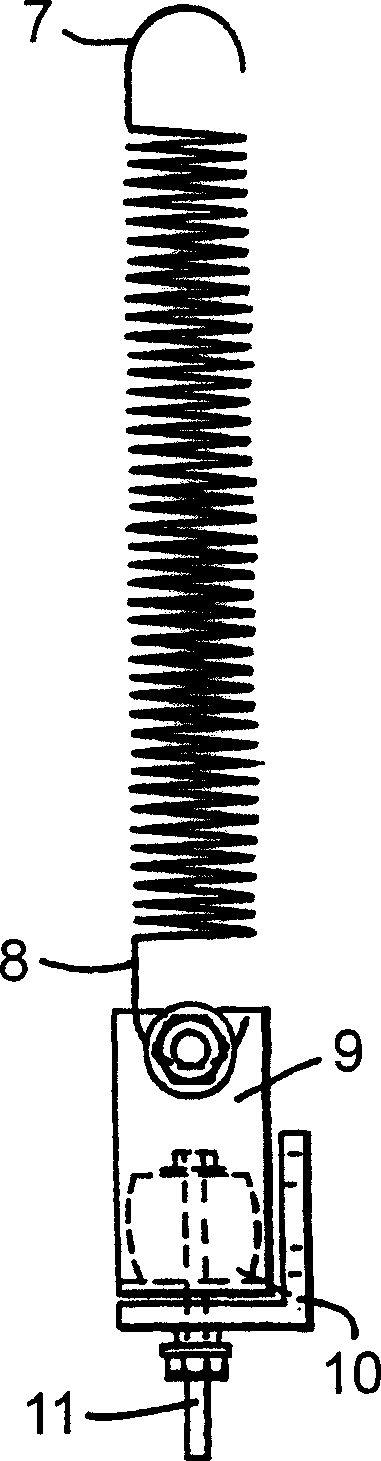

[0029] The Stirling engine assembly comprises a Stirling engine 1, which is well known in the art. The Stirling engine has a displacer and a power piston, both arranged to reciprocate in a vertical direction. This produces a net vertical vibration of the Stirling engine 1 itself.

[0030] In order to reduce this vibration, the damper mass 2 is supported by compression springs 3 above and below the damper mass 2 . This structure is housed in a casing 4 which is rigidly fixed to the bottom of the Stirling engine 1 . The mass 2 and spring 3 are adjusted such that the damper mass 2 vibrates as closely as possible in anti-phase to the Stirling engine 1 when the Stirling engine 1 is operating at the normal operating frequency. Thus, the overall vibration of the Stirling engine 1 and housing 4 is greatly reduced.

[0031] The current structure includes 8 compression springs 3 above and 8 compression springs 3 below the shock absorber mass 2 of 10.5 kg (±10%). For example, these s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com