Turbocharger rotor unbalance amount control method based on dynamic characteristics

A turbocharger and rotor unbalanced technology, applied in static/dynamic balance testing, instruments, measuring devices, etc., can solve problems such as increased production and maintenance costs, unbalanced vibration control, and large vibration of turbochargers. Achieve the effects of reducing unbalanced vibration faults, prolonging service life, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

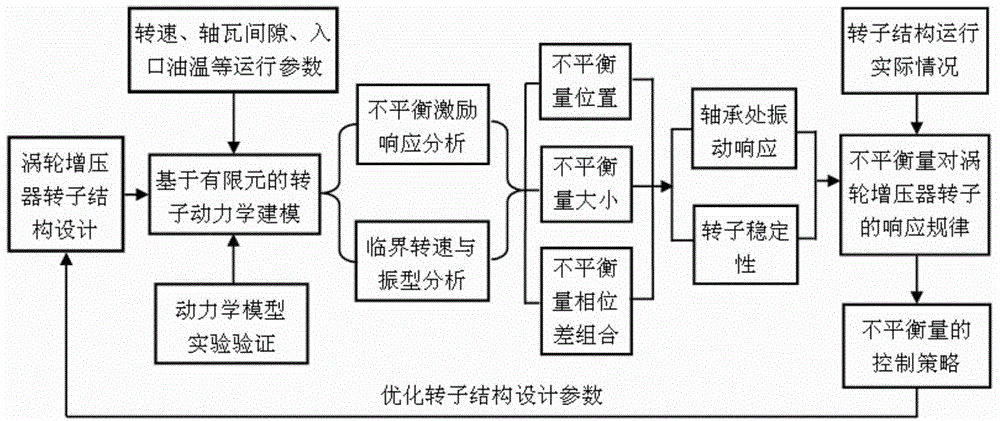

[0030] like figure 1 Shown, the present invention comprises the steps:

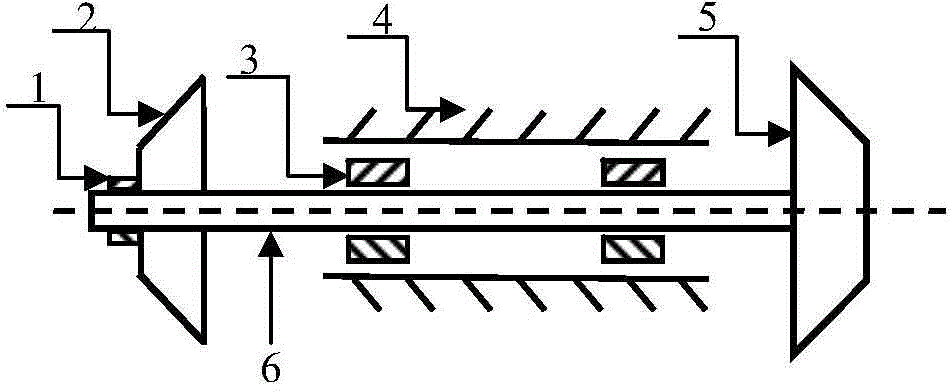

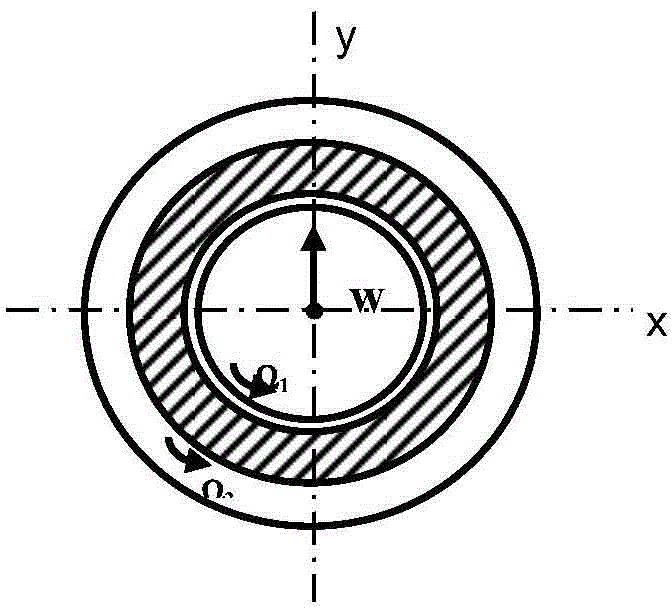

[0031] 1) When designing a turbocharger, analyze the structural characteristics of the rotor bearing of the turbocharger, and establish the motion control equation of the rotor system Where M is the mass matrix, C is the external damping matrix of the system, G is the gyro force matrix, K is the system stiffness matrix, q, with represent displacement, velocity and acceleration respectively, F i is the internal oil film force of the supporting journal, F ub is the unbalanced force, F s is the static load gravity. According to the structural size parameters of the floating ring bearing, combined with the bearing bush installation clearance, lubricating oil temperature, lubricating oil viscosity, floating ring bearing speed and the actual operating parameters of the static load at the two bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com