Shearing control method and control device of disc shear

A control method and technology of control device, applied in shearing device, digital control, electrical program control, etc., can solve the problem of economic waste, personnel/technical modification and re-adaptation, high failure rate of broken edge jam chute, technical and economic disadvantage, etc. problems, to achieve the effects of reduced management and maintenance work intensity and spare parts consumption, stable and efficient continuous production, and stable vibration and current values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

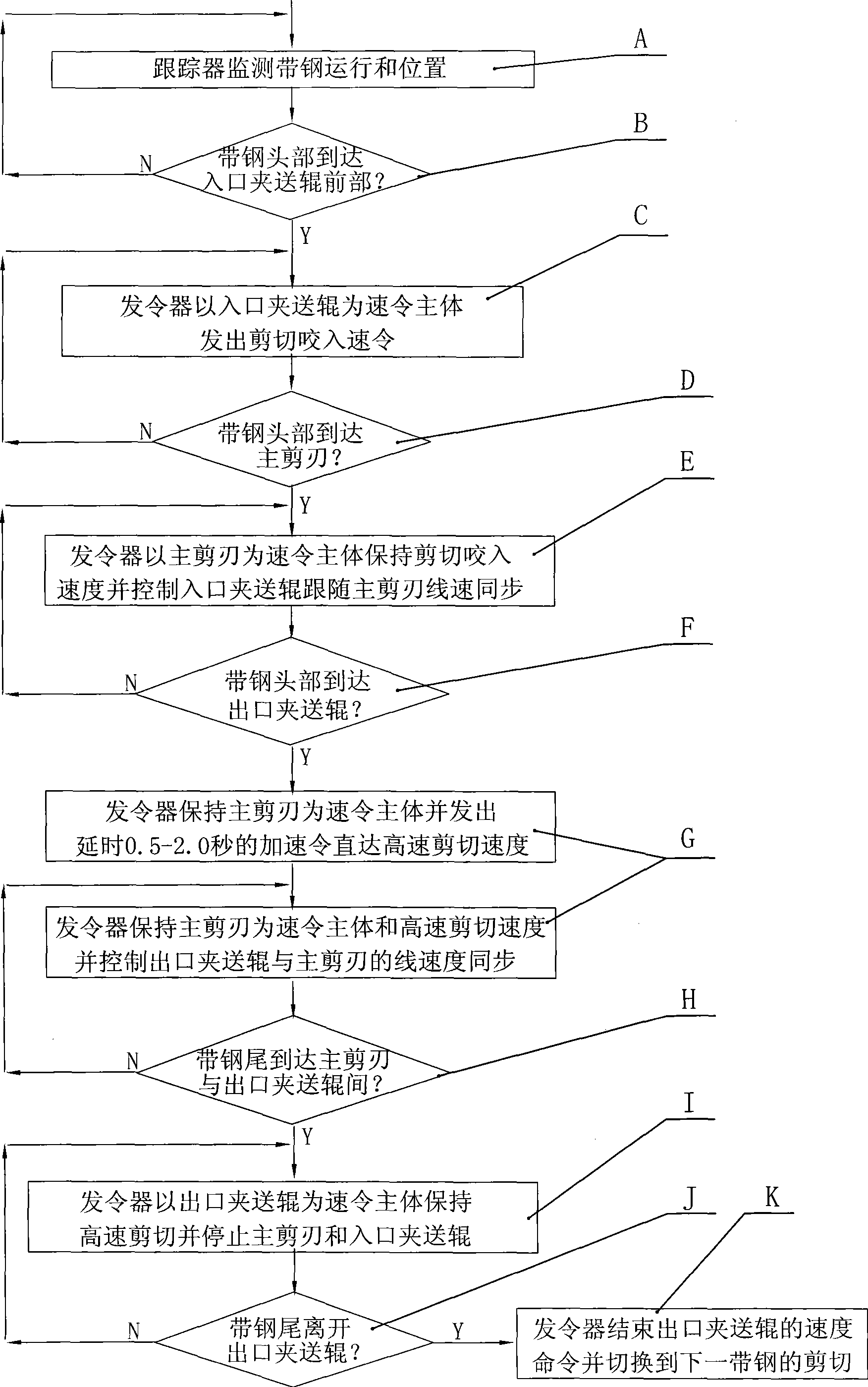

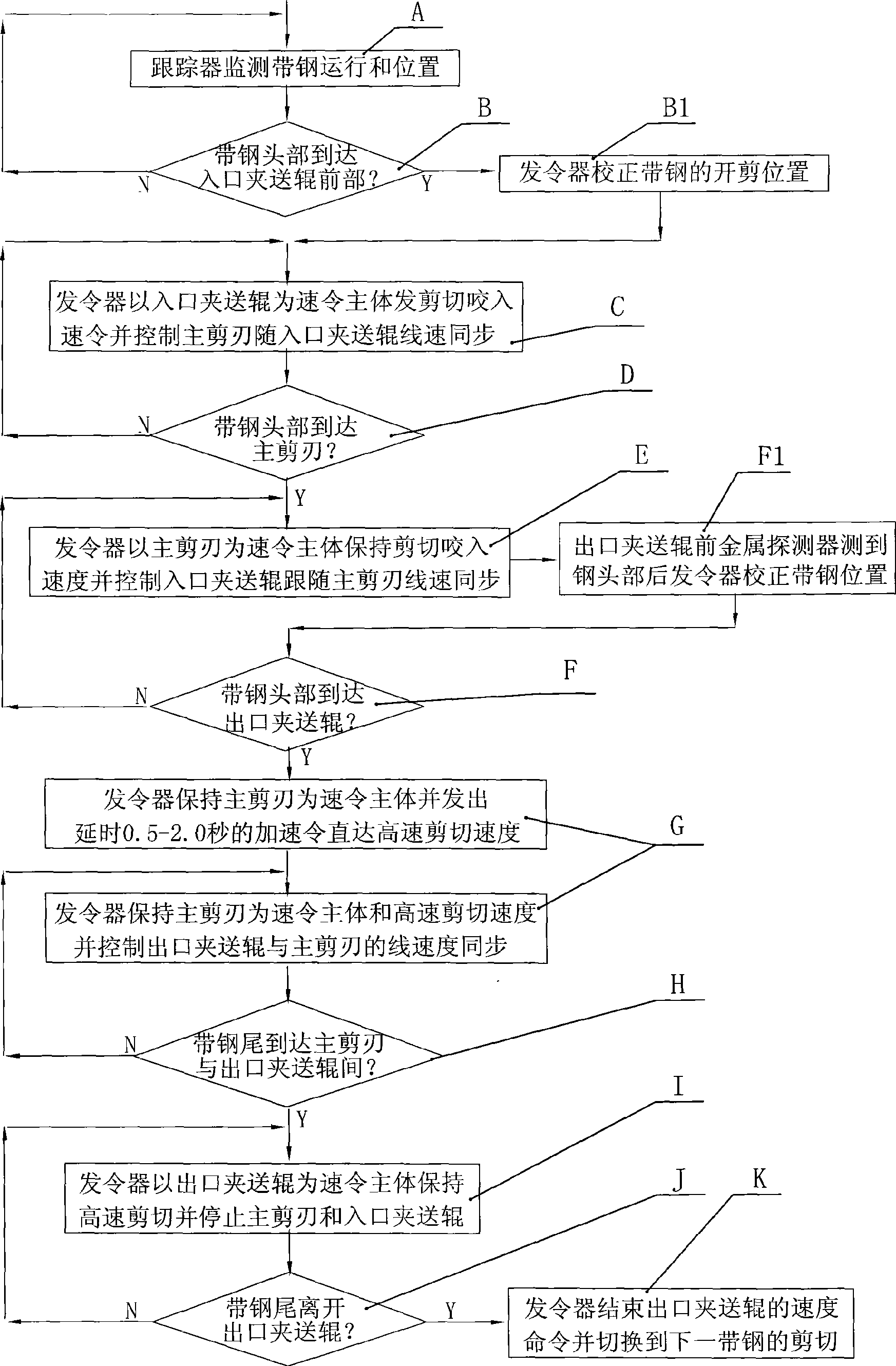

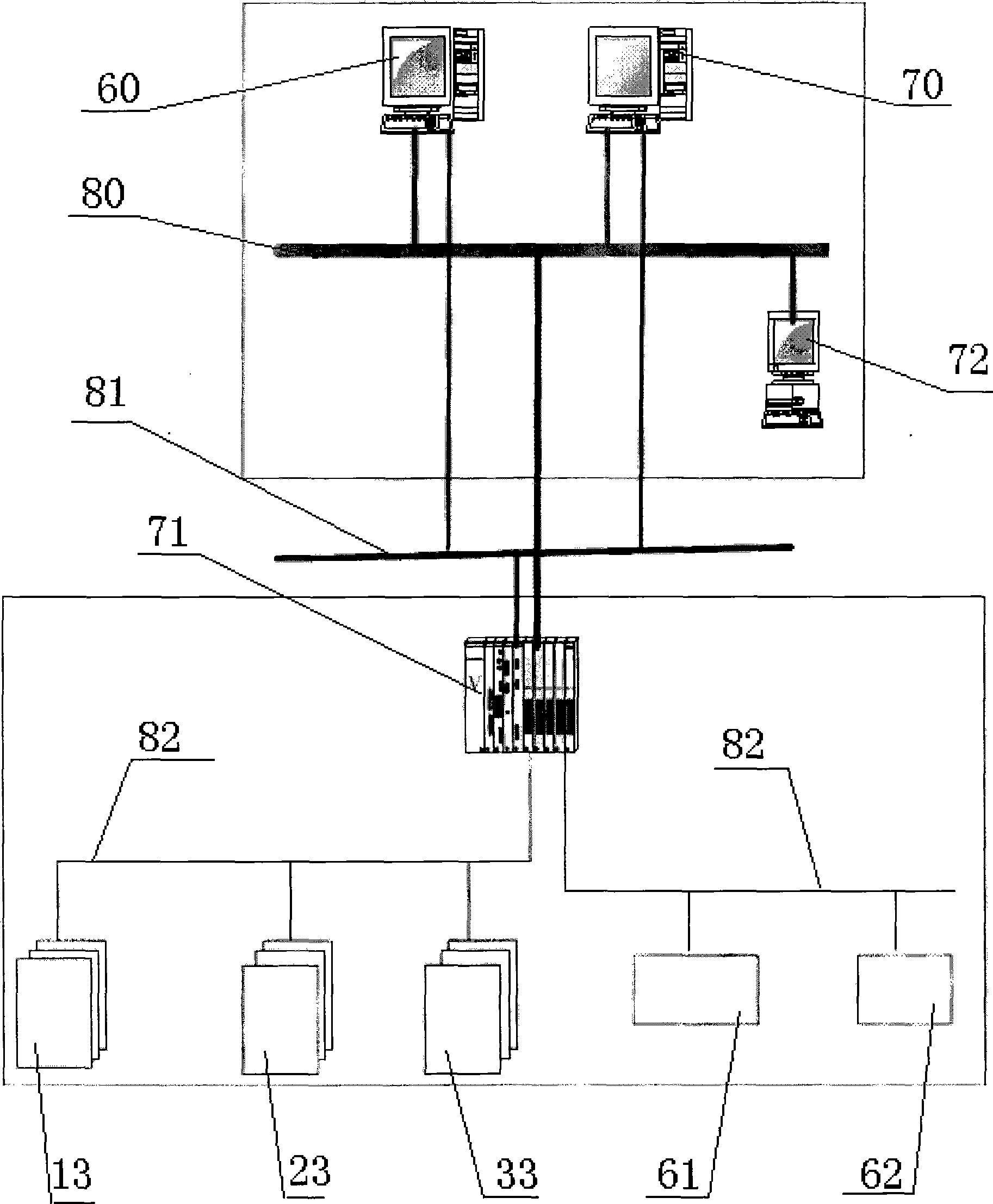

[0055] like figure 2 , is a schematic block diagram of Embodiment 2 of the method of the present invention. In this method, the disc shears include an inlet pinch roller, a main shear blade, an outlet pinch roller, and a conveying roller table, the pinch roller includes an upper roller and a lower roller, and the main shear blade includes a lower shear blade and an upper roller The cutting edge, the control device of the disc shears includes a tracker for tracking the position of the steel strip, a starter for outputting control commands, a speed regulator for each pinch roller and the main cutting edge,

[0056] The tracker includes a computer, and also includes a speed measuring sensor arranged on the side of each pinch roller lower roller 2 and the side of the main shear edge 2, and the computer collects the speed data of each speed measuring sensor and performs mathematical calculation to track the operation of the strip steel Location;

[0057] The control device also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com