Induction type ultrasound electric principal shaft

An inductive and ultrasonic technology, applied in asynchronous inductive clutches/brakes, electromechanical devices, electrical components, etc., can solve the problems of low reliability, bulky, and many power transmission links, and achieve high rotation accuracy and smooth rotation. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

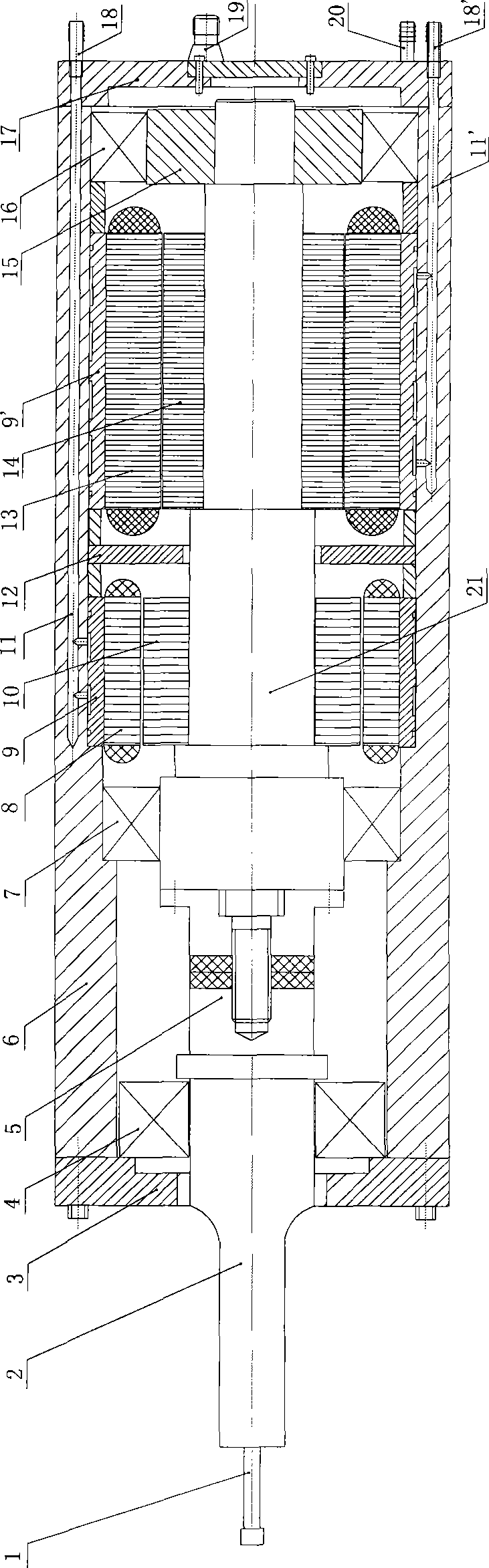

[0021] exist figure 1 In the specific structure diagram of the present invention shown, comprise main shaft 21, housing 6, front bearing 4, middle bearing 7, rear bearing 16, motor rotor 14, motor stator 13, shielding ring 12, ultrasonic transducer 5, transformer Spindle 2, tool head 1, ultrasonic transmitter 8, ultrasonic receiver 10 and other parts. The whole spindle is divided into front and rear parts, the front part is the ultrasonic vibration system, and the rear part is the electric spindle part. Front end cover 3, front bearing 4, middle bearing 7, ultrasonic transmitter 8, water sealing cover 9, shielding ring 12, motor stator 13, water sealing cover 9, 9', rear bearing 16 and rear end cover 17 are installed in the shell On the body 6, a shielding ring is provided between the motor and the ultrasonic signal transmission system to isolate electromagnetic field interference between the two. The rear end of the main shaft is covered with a rear bushing 15. The function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com