Vertical molding mold and system and application method for concrete utility tunnel

A technology for forming molds and integrated pipe gallery, which is applied to molds, ceramic molding machines, auxiliary parts of molds, etc., can solve the problems of single warehouse integrated pipe gallery being unable to meet the needs of use and incompatibility, and reduce the use of cranes, pouring The effect of fast speed and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0204] According to the third embodiment provided by the present invention, a method for molding a concrete integrated pipe gallery is provided, that is, a method for molding a concrete integrated pipe gallery by using the above-mentioned vertical forming mold for a concrete integrated pipe gallery. Include the following steps:

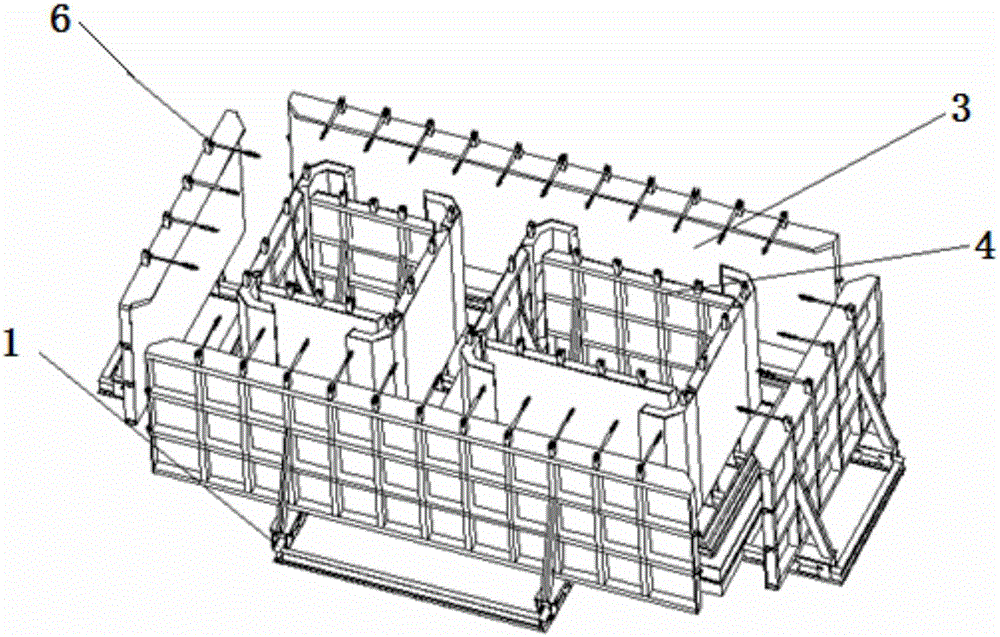

[0205] 1) Mold assembly: clean the mold, apply release agent, fix the mold base 1 on the ground, place the steel skeleton, install the socket end mold 2, install the inner mold mold 4, install the outer mold mold 3, and lock the locking device 6 ;

[0206] 2) Feeding and vibrating: concrete pouring and vibrating; concrete molding and plastering;

[0207] 3) Steam curing: steam curing is adopted, and a supporting canvas steam curing cover is used;

[0208] 4) Demoulding: Demoulding in the reverse order of mold assembly.

[0209] Preferably, the method also includes:

[0210] 5) Pipe gallery overturning: use hydraulic overturning equipment to turn the...

Embodiment 1

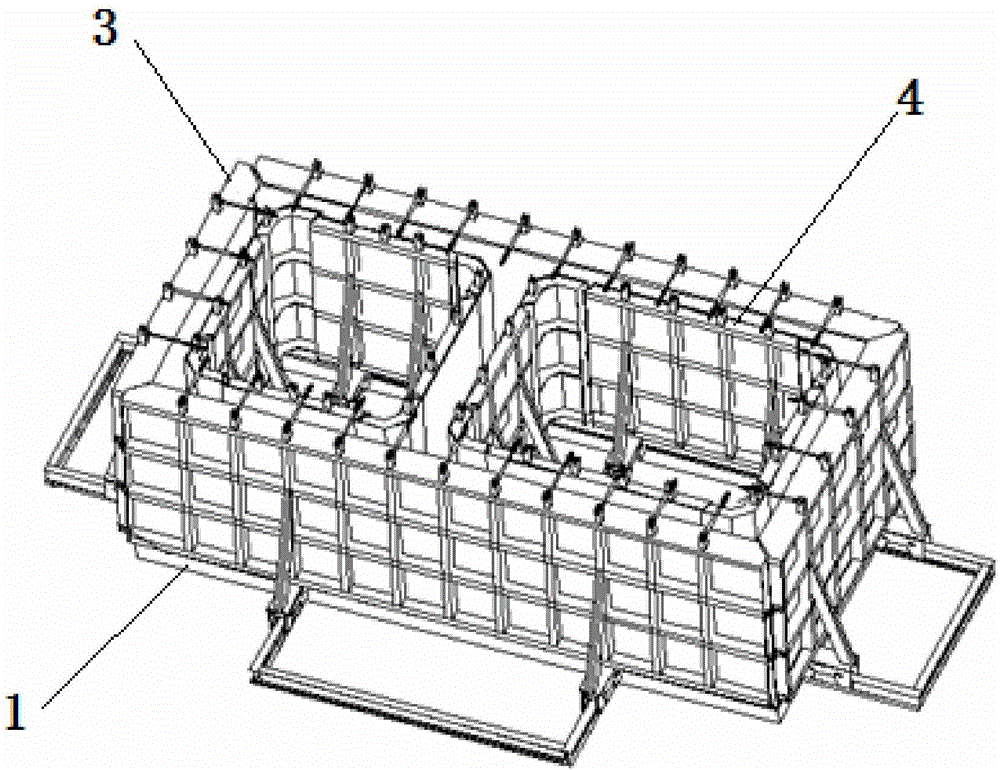

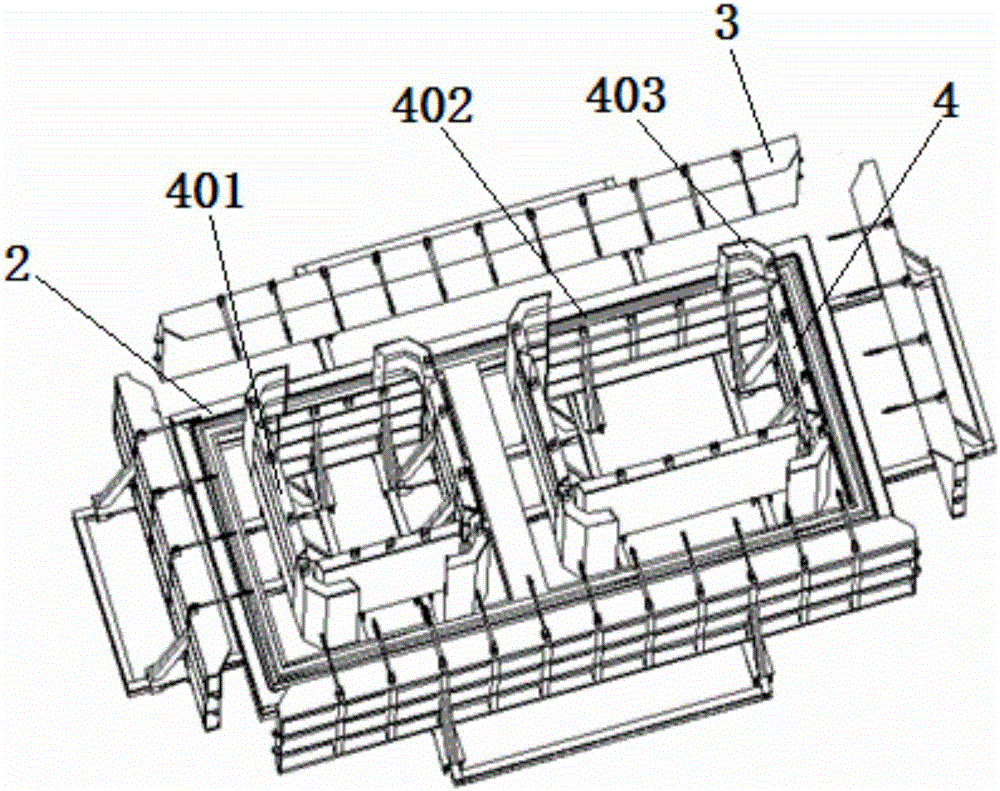

[0214] A vertical forming mold for a concrete comprehensive pipe gallery, the mold includes a mold base 1, a socket end mold 2, an outer mold mold 3, and an inner mold mold 4. Wherein: the mold base 1 is fixed on the ground. The socket end mold 2 is arranged on the mold base 1 . The outer mold 3 is arranged on the mold base 1 and is located around the outside of the socket-end mold 2 . Three internal molds 4 are arranged on the mold base 1 and are located around the inner side of the socket end mold 2 . The length of the entire inner mold is 8m; the height is 3.6m; the width is 2m. The 3 insider molds are the same size.

[0215] Outer mold guide rails 101 are respectively provided around the outside of the mold base 1 . The outer mold guide rails 101 on each side of the mold base 1 are perpendicular to the edges on each side of the mold base 1 . The outer mold guide rail 101 is an I-shaped steel guide rail. The inner side of the mold base 1 is provided with an inner mold...

Embodiment 2

[0220] Example 1 is repeated except that the mold comprises two inner mold molds 4 . Wherein the length of the entire inner mold mold is 6m. The width is 2m. The height is 3m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com