Uniform distribution type pulsating flow generating device for vibration induction of elastic tube bundles inside heat exchanger

A technology of tube bundle vibration and generating device, which is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc. It can solve the problem of inability to achieve the expected vibration of enhanced heat exchange, inconsistent pulsating flow intensity and frequency, and stable flow and flow. It can improve the uneven vibration, avoid fatigue damage, and achieve the effect of uniform vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

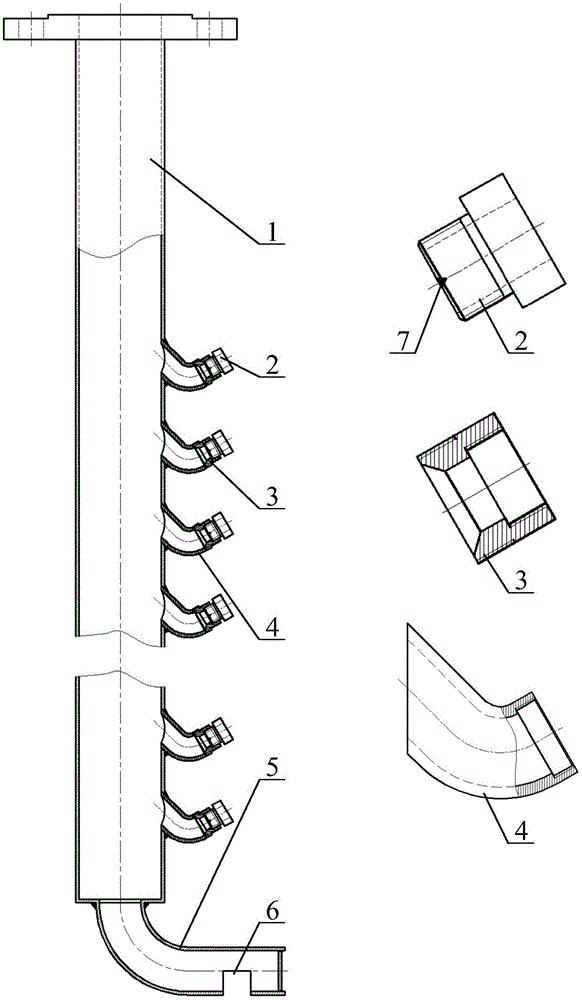

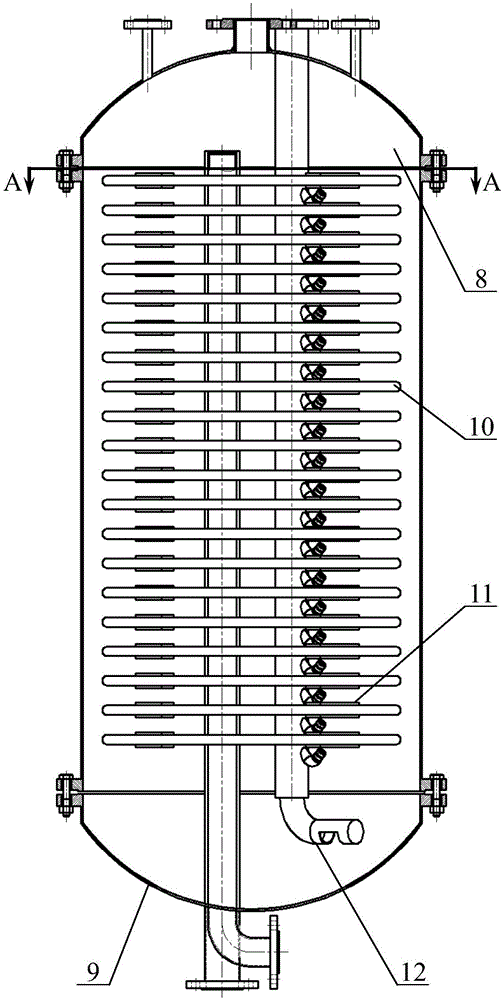

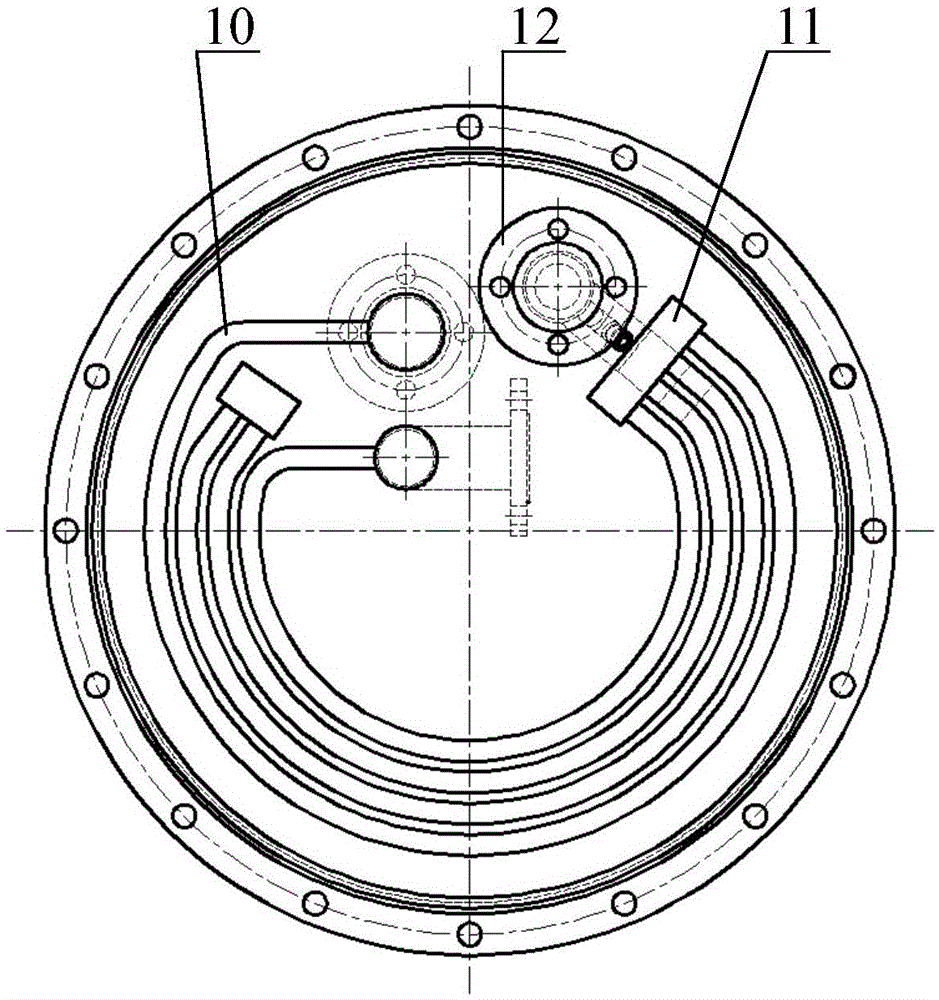

[0027] Such as figure 1 As shown, the uniformly distributed pulsating flow generating device 12 used for vibration induction of elastic tube bundles in heat exchangers of the present invention includes a vertical pipe 1, a branch elbow 4, a flow guide pipe 3, a pulsating flow pipe 2, and a shell-side water inlet pipe 5 and spoiler 7. Branch bends 4 are distributed outside the standpipe 1 , and the distances between adjacent branch bends 4 are consistent. One end of each branch elbow 4 is welded on the standpipe 1 and communicated with the standpipe 1 , and the other end is connected with a diversion pipe 3 connected with a pulsating flow pipe 2 . The axis included angle (bending angle) between the two curved sections in the branch elbow 4 is 75°-120°. The axis of the section connected to the vertical pipe 1 on the branch elbow 4 and the lower section of the vertical pipe axis 1 (on the axis of the vertical pipe at the intersection of the two axes (the intersection of the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com