Laser fine-adjustment device for installing and positioning anchorage prestressing steel pipe

A technology of installation positioning and laser fine-tuning, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large construction measurement and lofting workload, unguaranteed construction accuracy, low labor productivity, etc., to achieve equipment processing and production. The effect of low cost, reduced construction cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

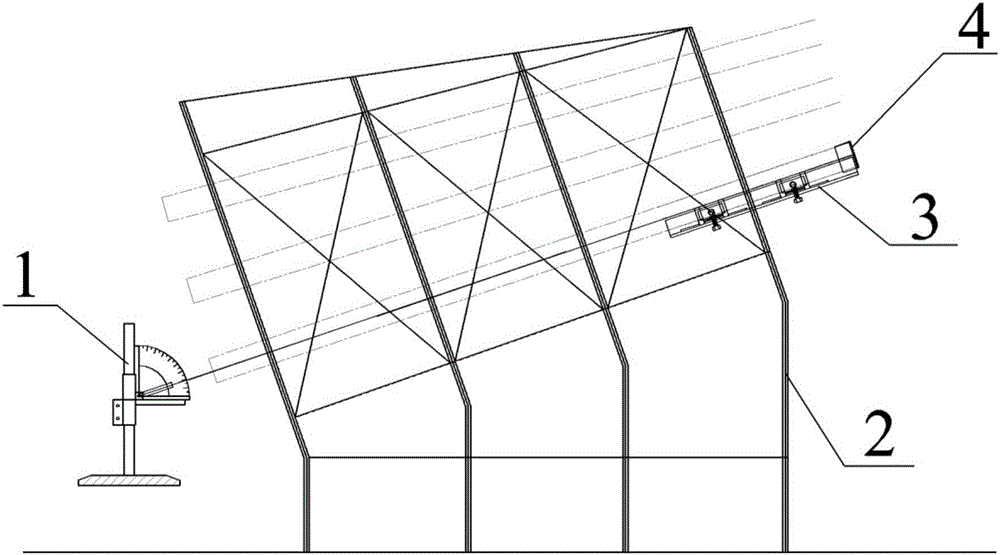

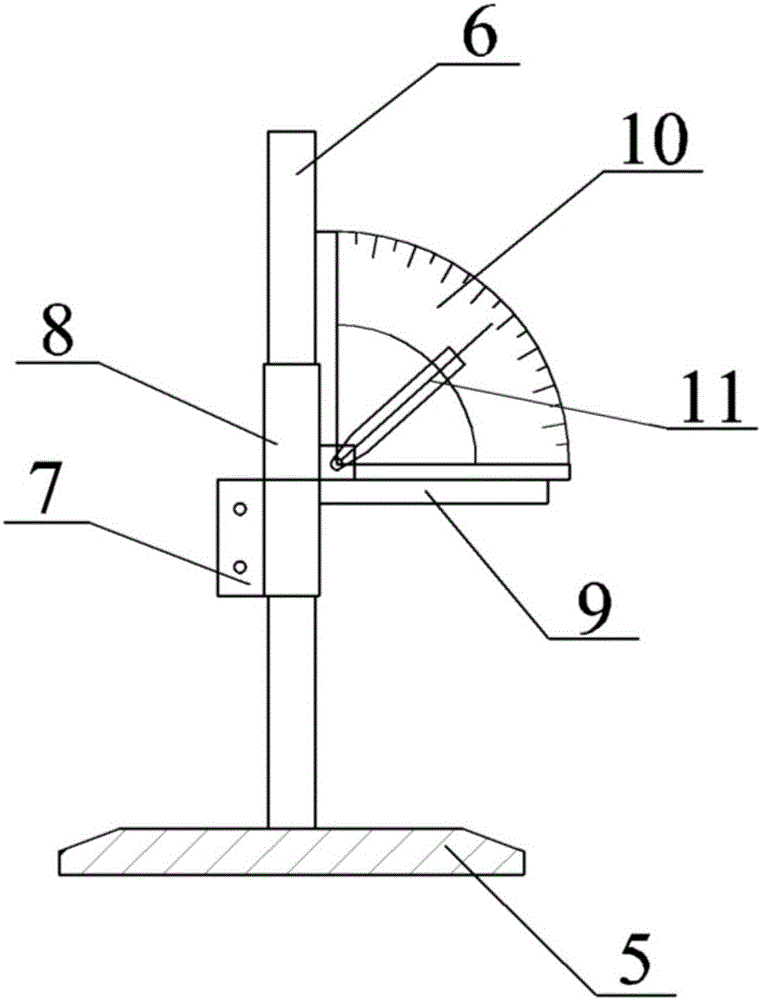

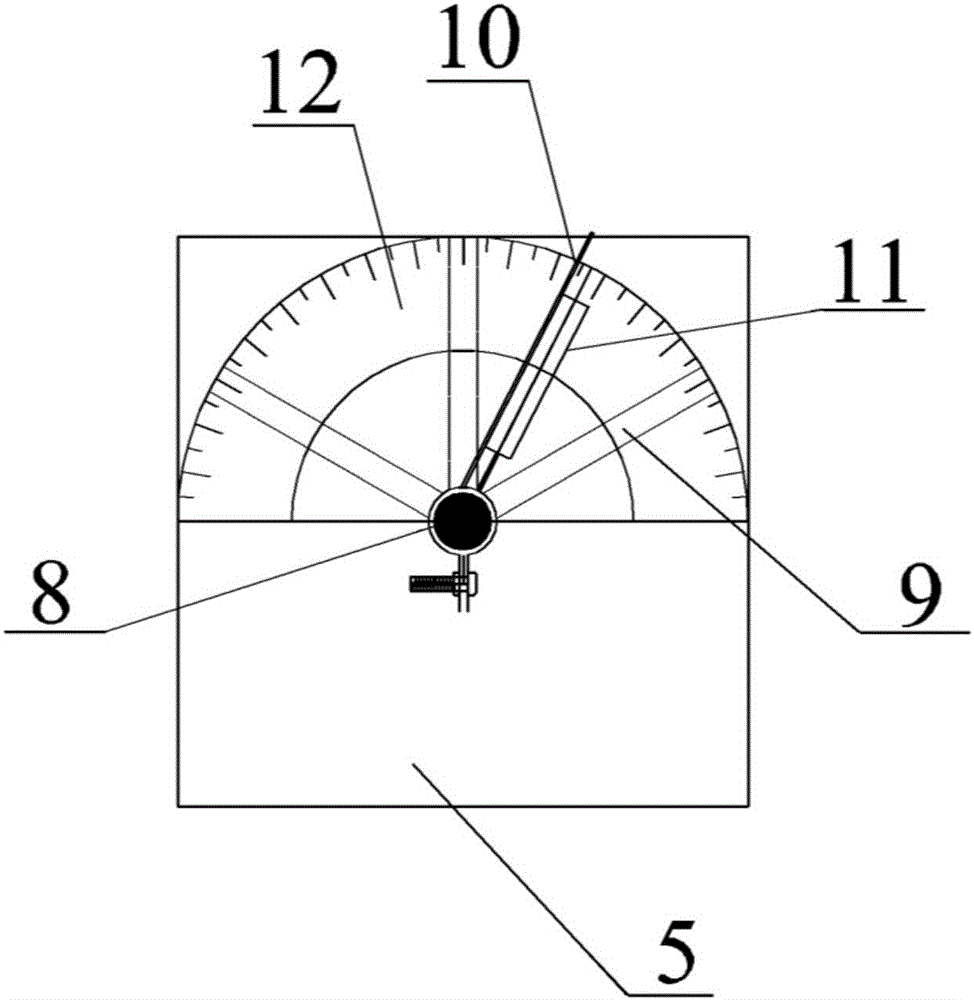

[0029] like figure 1 As shown, a laser fine-tuning device for anchoring prestressed steel pipe installation and positioning, including a starting device 1 for fixing the laser pointer and adjusting the angle, a fixing bracket 2 for fixing the prestressed steel pipe, and a receiving device 4 The laser pen is arranged on one end of the prestressed steel pipe by the originating device 1, and the receiving device 4 is arranged on the other end thereof, for receiving the laser light emitted from the other end of the prestressed steel pipe through one end; near the receiving device 4 side, The fixed bracket 2 is provided with a fine-tuning device 3; the fine-tuning device 3 includes a U-shaped sliding bracket arranged on the lower part of the prestressed steel pipe and adjusting screws respectively arranged on the bottom of the prestressed steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com