Prefabricated reinforced concrete pipe pile with ground source heat pump double-helical tubular heat exchanger

A reinforced concrete pipe, ground source heat pump technology, applied in heat pumps, sheet pile walls, refrigerators, etc., can solve the problems of heat exchange efficiency and thermal conductivity of backfill materials, and achieve water pollution and water waste. The effect of saving related costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

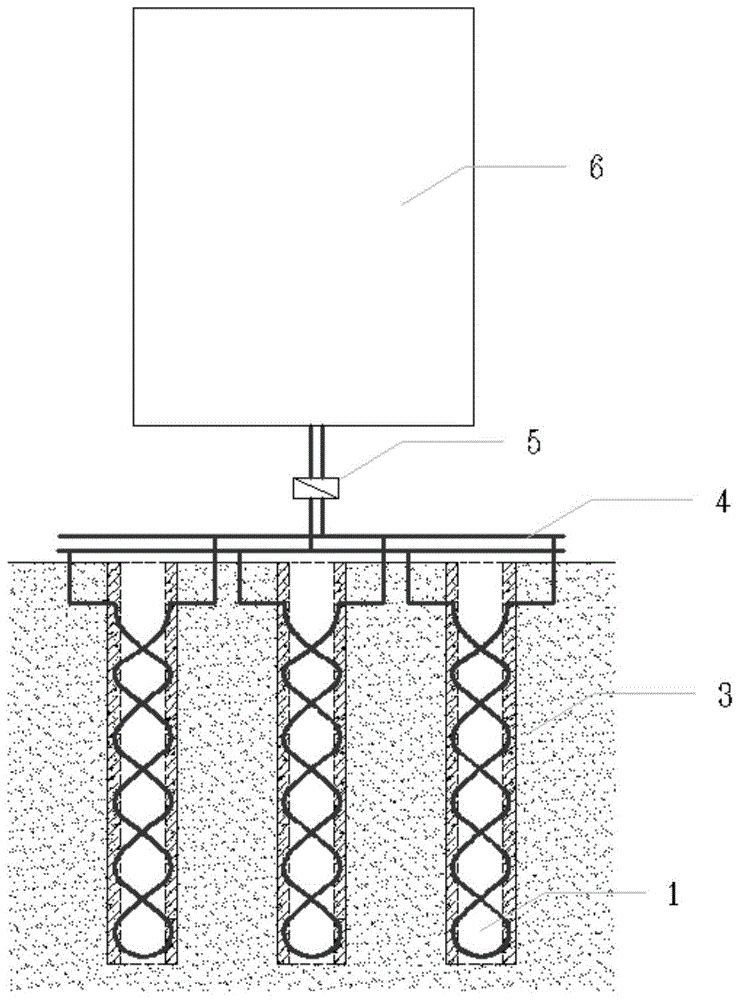

[0028] exist figure 1 In winter, the heat in the soil layer 3 is taken out through the exchange medium in the double helix tubular heat exchanger 2 filled in the prefabricated reinforced concrete pipe pile 1 with the ground source heat pump double helix tubular heat exchanger, and the heat in the soil layer 3 is taken out through the surface exchange tube. The road 4 and the ground source heat pump unit 5 provide heating to the building 6; in summer, the waste heat in the building 6 is taken out, through the surface exchange pipeline 4, the ground source heat pump unit 5 and filled in the double helical tubular heat exchanger with the ground source heat pump The exchange medium in the double-helix tubular heat exchanger in the prefabricated reinforced concrete pipe pile 1 is released into the soil layer 3 .

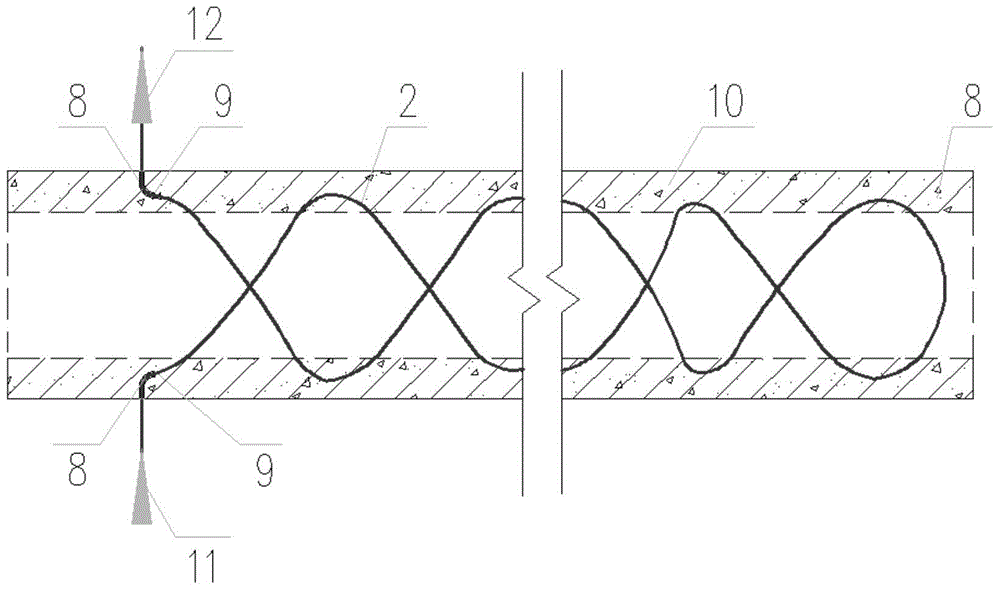

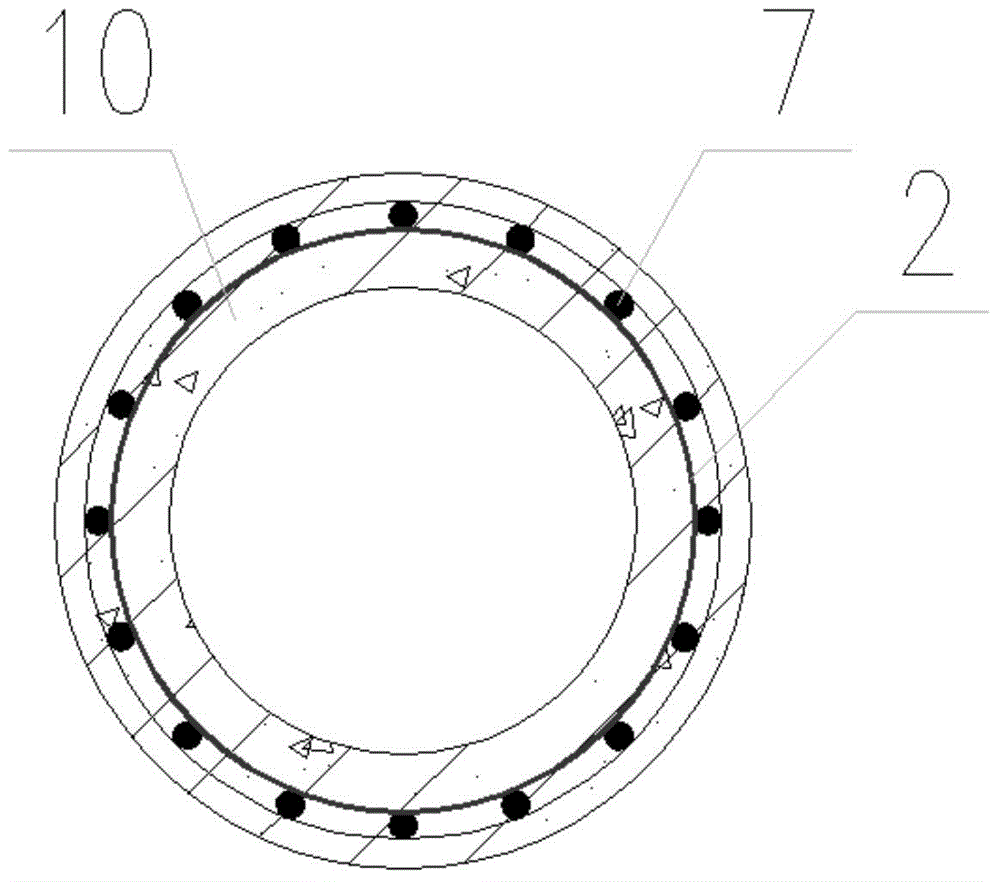

[0029] figure 2 , 3, 4 shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com