Manufacturing method of duplex stainless steel chemical ship side section

A technology of duplex stainless steel and manufacturing method, which is applied in ship construction, ship parts, ships, etc., can solve the problems of difficult construction of side sections of duplex stainless steel chemical tankers, so as to improve construction efficiency, reduce deformation, and ensure construction accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The manufacturing method of the side section of the duplex stainless steel chemical tanker of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific examples of implementation, in order to express the technical solution of the present invention more clearly, but it cannot be limited by this protection scope of the present invention.

[0036] A method for manufacturing a side section of a duplex stainless steel chemical tanker, comprising the following steps:

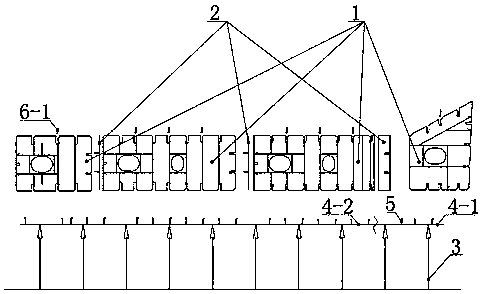

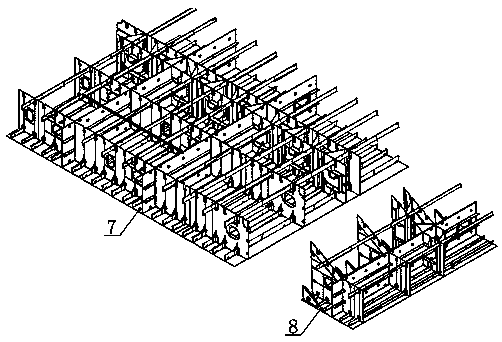

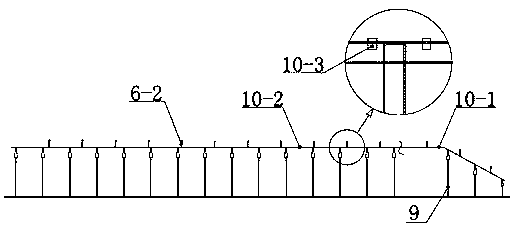

[0037] Step 1, carbon steel outer plate secondary assembly construction, such as figure 1 As shown, manufacture the rib plate group 1, the platform plate group 2, the vertical outer plate frame 3, lay the upper outer plate 4-1, the lower outer plate 4-2 on the outer plate frame 3, and the upper outer plate 41 and the lower outer plate The panels 42 are assembled, the upper outer panel 41 and the lower outer panel 42 are constructed in the same tire, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com