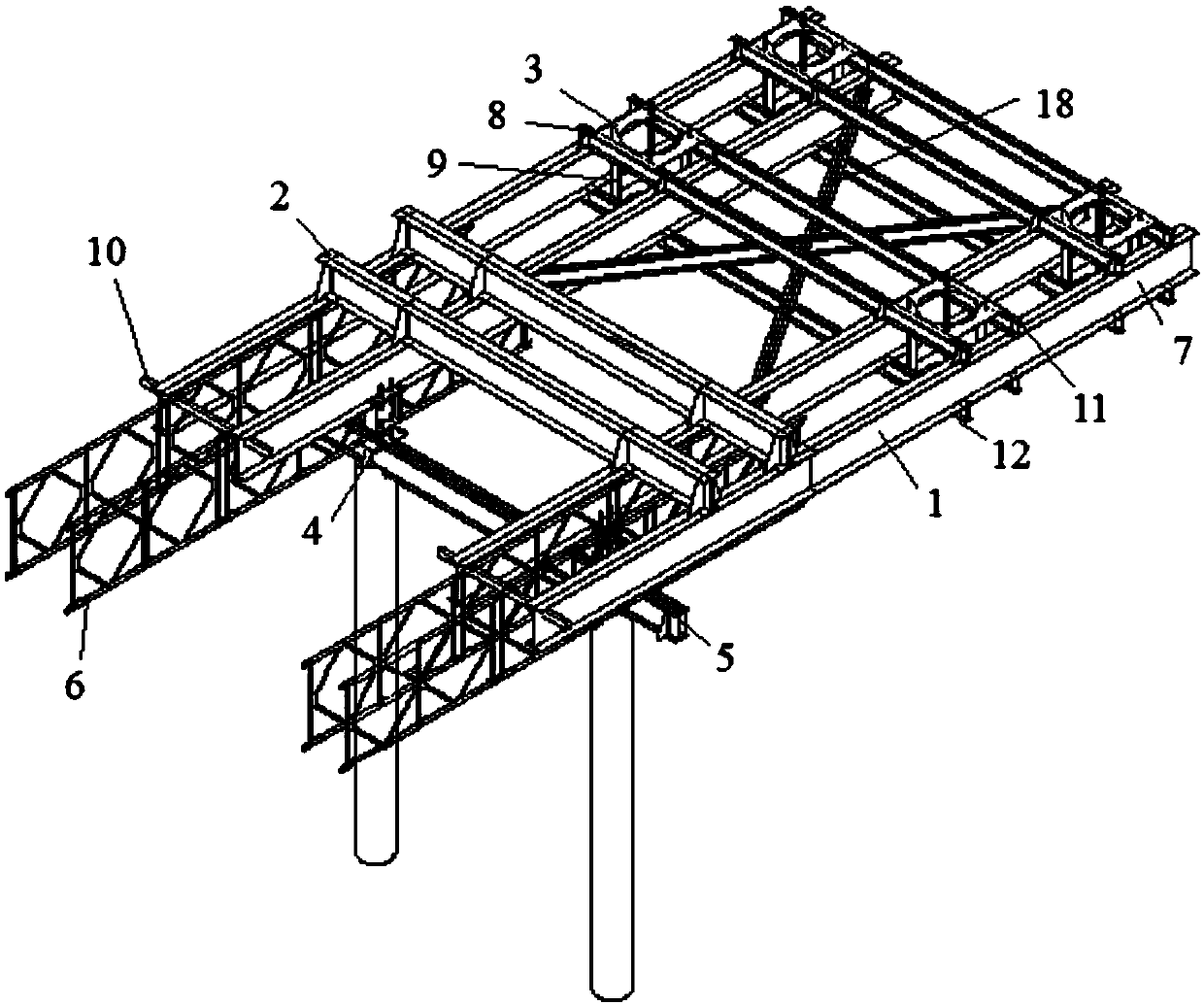

Steel pipe pile guiding frame structure and construction method

A technology of guide frames and steel pipe piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve the problems of lifting equipment lifting and steel pipe pile foundation construction, construction accuracy, piling platform stability, and easy Affected by wind, waves and water depth, it achieves the effect of simple structure, low cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

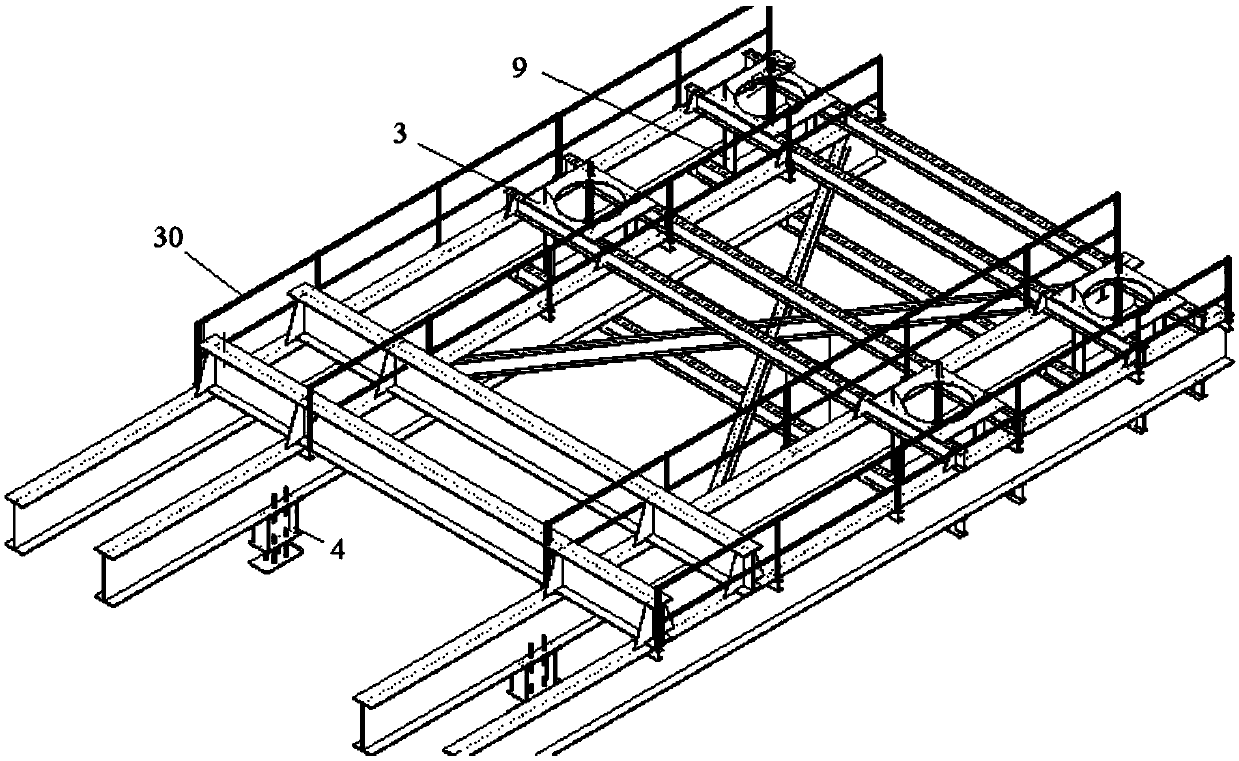

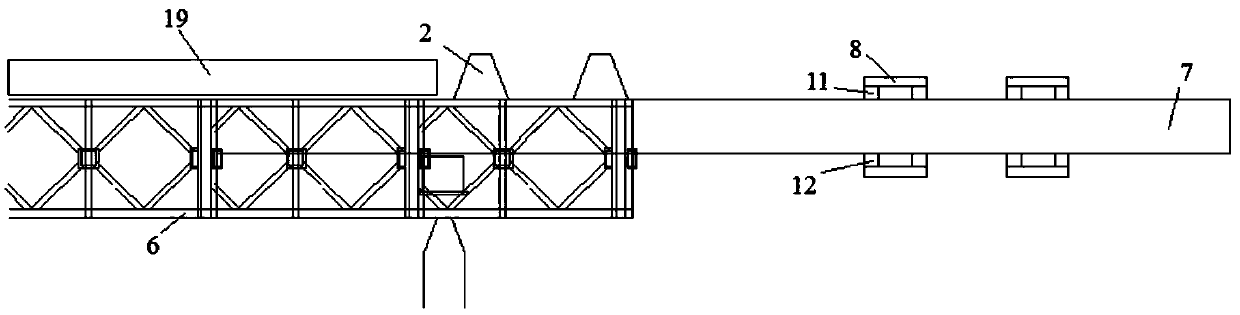

[0106] The main girders 7 are two pairs, using four 12.85m-long H700 steels, which are arranged side by side horizontally and parallel to the longitudinal direction of the trestle. Each steel beam has a reserved hole for the bolt 10 at the same position on the rear web, and is welded with the crossbeam 2. Connect with the pin 10 through a perforation;

[0107] The latch 10 of the present embodiment adopts two grooves 12.6 section steel with a length of 2.5m, which are horizontally placed in the web of the main beam 7, and are connected with the main beam 7 and the Bailey frame 6 in a perforated manner;

[0108] The crossbeam 2 of this embodiment adopts two HM588 type steels with a length of 8 m, which are vertically arranged above the main beam 7 in the horizontal direction, and welded with four main beams 7;

[0109] The railings 30 of this embodiment are welded by Φ48×3.6mm scaffolding tubes, four rows in total, arranged vertically above the main beam 7 in parallel, and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com