Subway unballasted track ditch construction method and used formwork

A ballastless track and construction method technology, applied in the direction of the road bottom, buildings, etc., can solve the problems of difficult control of the longitudinal slope of the ditch bottom, inaccurate installation of the formwork, complicated construction procedures, etc., to reduce the probability of peeling, Simple and convenient demoulding, solve the effect of easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

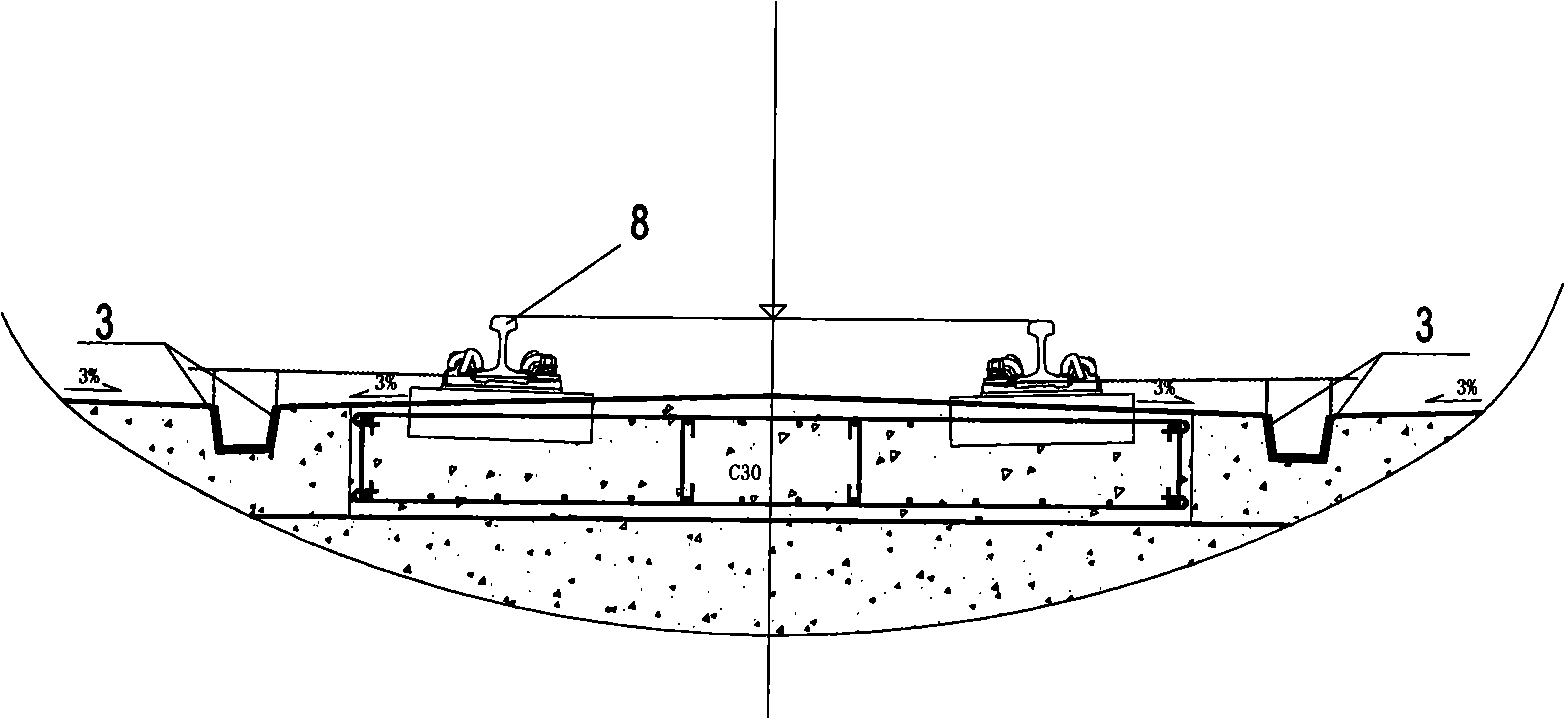

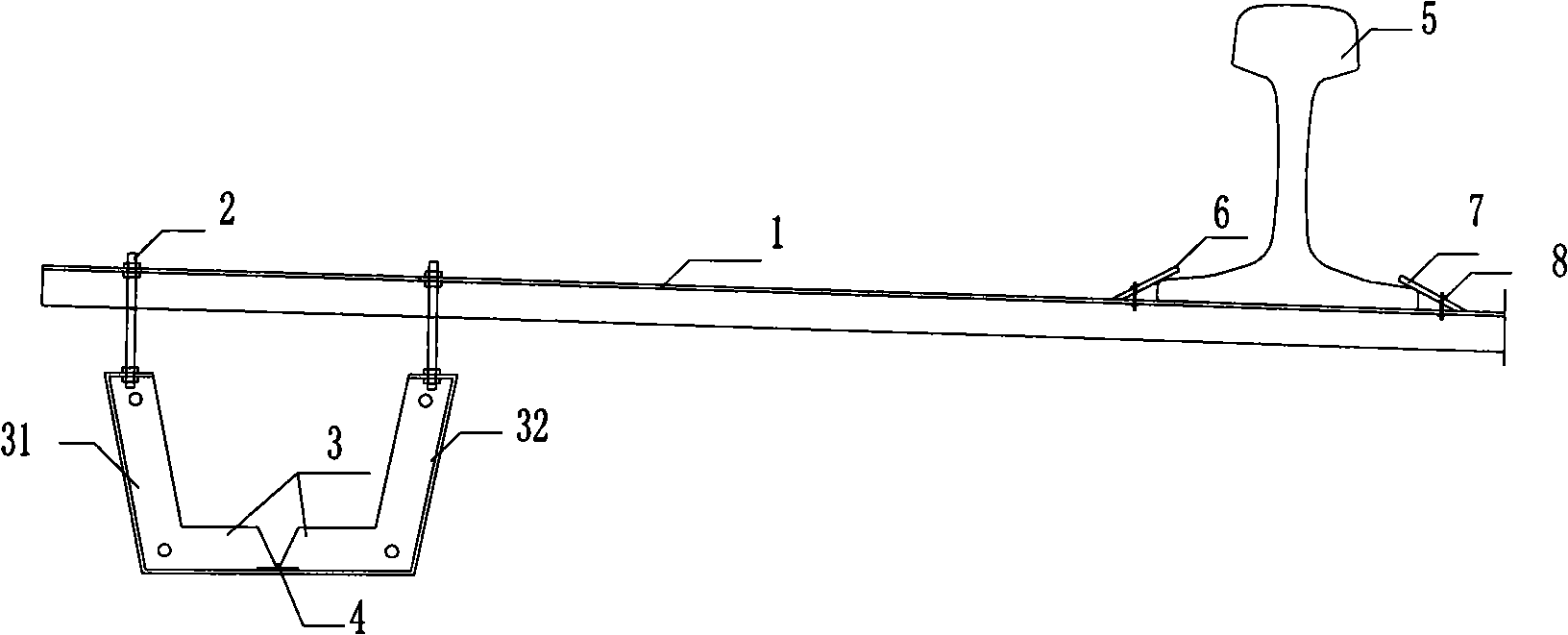

[0022] The ballastless track ditch construction method is used to construct a straight line section of a subway track. The formwork 3 used in the construction has a groove-shaped cross-section and is composed of two symmetrical L-shaped formworks 31 and 32, each with a length of 2.5 meters. , two L-shaped formworks are connected at the bottom by hinges 4, and the upper part of the formwork 3 is connected with suspenders through bolts 2 at intervals of 1.25 meters. At the bottom of the rail 5, the crimping piece 6 is composed of a crimping piece 7 and a bolt 8.

[0023] Its construction process includes the following steps:

[0024] (1) Preliminary installation of ballastless track gutter formwork

[0025] Place one side of the suspender 1 with the buckle 6 under the rail, adjust the position of the suspender 1 so that the bottom of the rail 5 is between the buckle 6 and the suspender 1, tighten the bolt 8 on the buckle 7, and put the suspender The rod 1 is fixed, and the two...

Embodiment 2

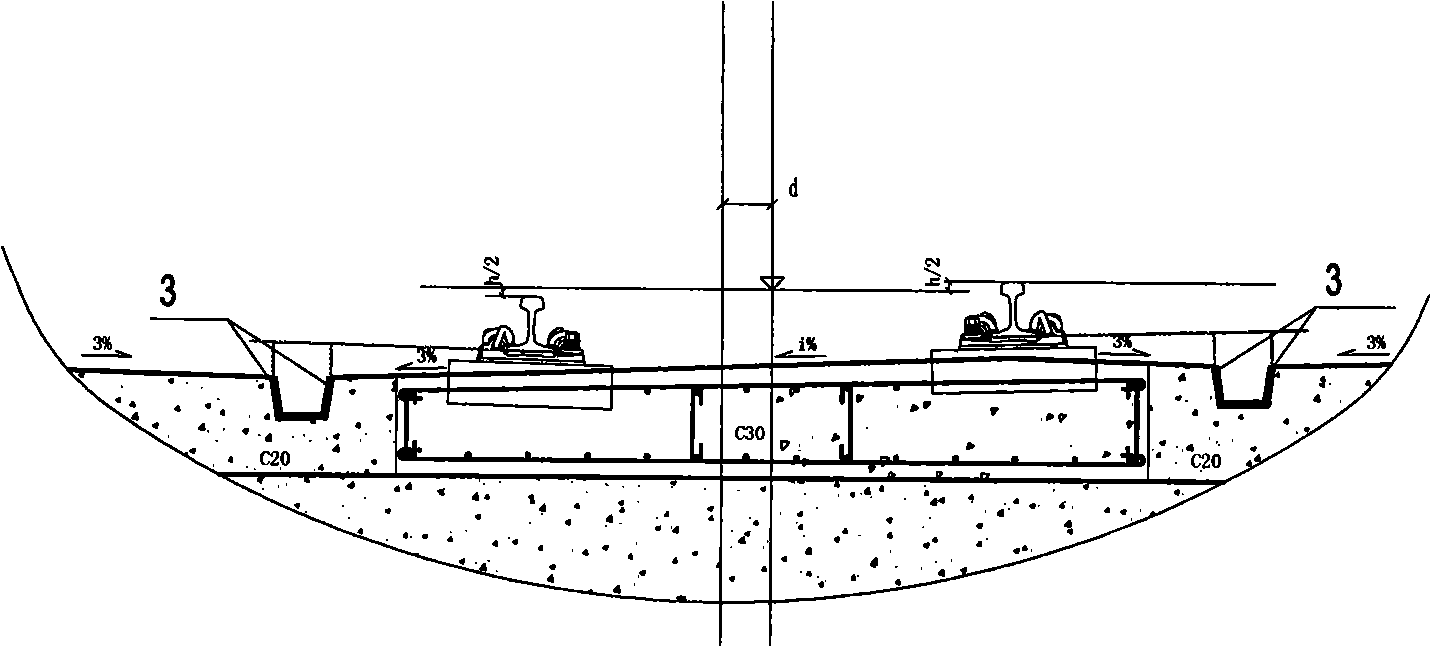

[0033] The ballastless track ditch construction method is used to construct a subway track curve section project. The formwork 3 used in the construction has a groove-shaped cross-section and is composed of two symmetrical L-shaped formworks 31 and 32, each with a length of 2 meters. , two L-shaped formworks are connected at the bottom by hinges 4 to form an integral formwork 3, and the upper part of the formwork 3 is connected with suspenders 1 by bolts 2 at intervals of 1 meter, and two suspenders 1 are installed in total. The fastening part 6 is fixedly connected to the bottom of the rail 5 , and the fastening part 6 is composed of a fastening piece 7 and a bolt 8 .

[0034] Its construction process includes the following steps:

[0035] (1) Preliminary installation of ballastless track gutter formwork

[0036] Place one side of the suspender 1 with the buckle 6 under the rail, adjust the position of the suspender 1 so that the bottom of the rail 5 is between the buckle 6 ...

Embodiment 3

[0044] Adopt ballastless track ditch construction method to carry out construction to certain subway track project, the structure of the formwork used in construction is the same as embodiment 1, adopts hinge 4 to link multi-section formwork 3 in construction, the length of each section formwork is 3 meters, the top of formwork every Suspenders 1 are connected by bolts 2 at intervals of 1.5 meters.

[0045] Its construction process includes the following steps:

[0046] (1) Preliminary installation of the ballastless track gutter formwork: Fix the suspender 1 to the rail bottom of the rail 5, connect the two L-shaped formworks through the hinge 4 to form an overall formwork 3 with a groove-shaped cross-section, and use the hinge 4 Connect multiple templates 3, and hoist the templates 3 on the boom 1 through bolts 2;

[0047] (2) accurately adjust the length of the bolt 2 to control the height of the template 3;

[0048] (3) Concrete is poured on the bottom and both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com