Construction method for steel structure arch rib of arch-type bridge

A construction method and steel structure technology, applied to bridges, arch bridges, bridge materials, etc., can solve the problems of increased construction cost, long period, and difficulty in guaranteeing construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

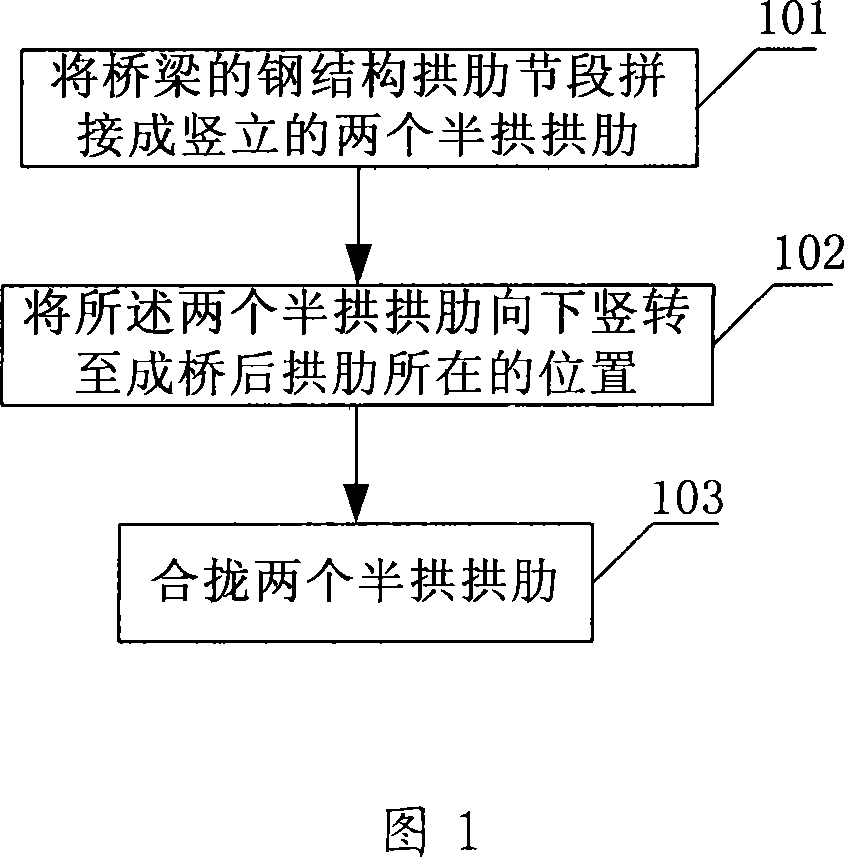

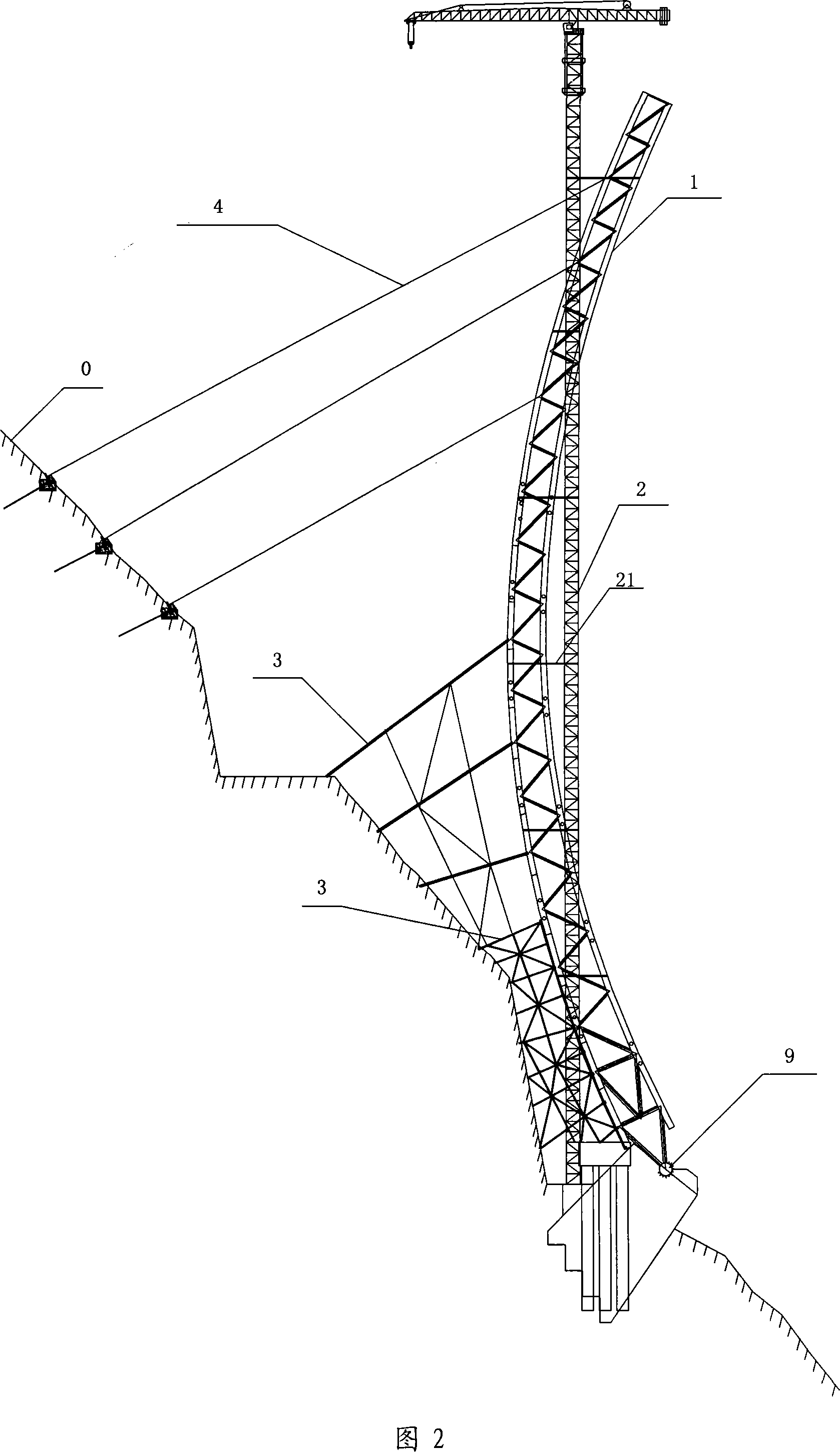

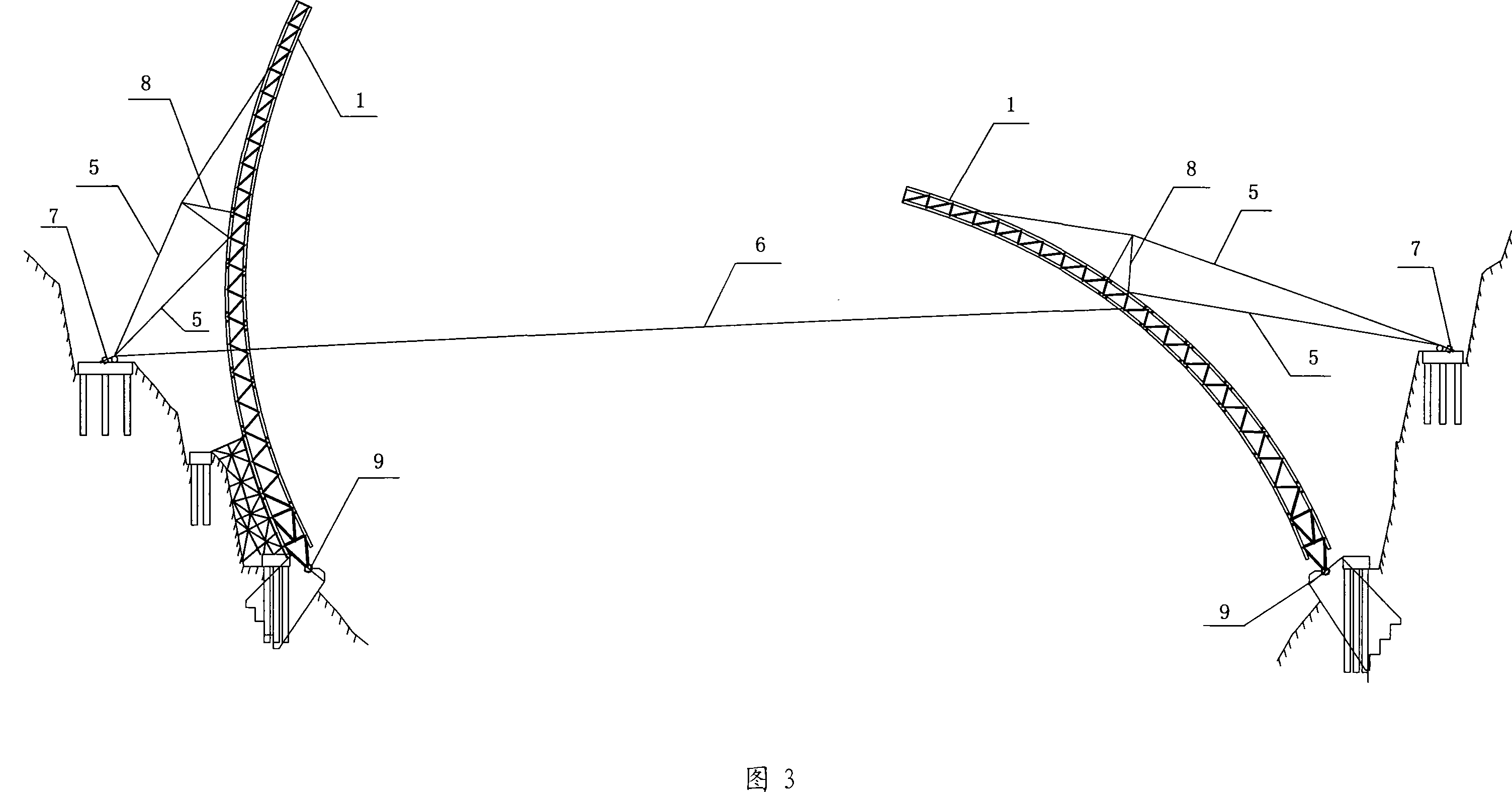

[0021] Fig. 1 is the flow chart of the construction method embodiment of the steel structure arch rib of the arch bridge of the present invention, this embodiment mainly lifts the segment of the steel structure arch rib by tower crane, and assembles the segment of the steel structure arch rib into a vertical half-arch rib . After completing the construction of the abutment foundation, arch rib support and tower crane foundation, first install the tower crane, and then carry out the construction of the bridge arch rib, specifically including:

[0022] Step 101, splicing the steel arch rib segments of the bridge into two erected half-arch ribs; taking the construction of one of the half-arch ribs as an example, the assembly process can be as follows:

[0023] Hoist the arch rib of the arch foot section with a tower crane, and first connect it with the rotating shaft on the abutment by bolts or welding; The rib segments are connected, hoisting and connecting the steel structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com