Track gauge correction method for double-block type ballastless track construction

A ballastless track, double-block technology, applied in the direction of track, track maintenance, road, etc., can solve the problems affecting the consistency of the gauge, reduce the number of replacement fasteners, improve the gauge inspection and correction process, and correct the operation simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

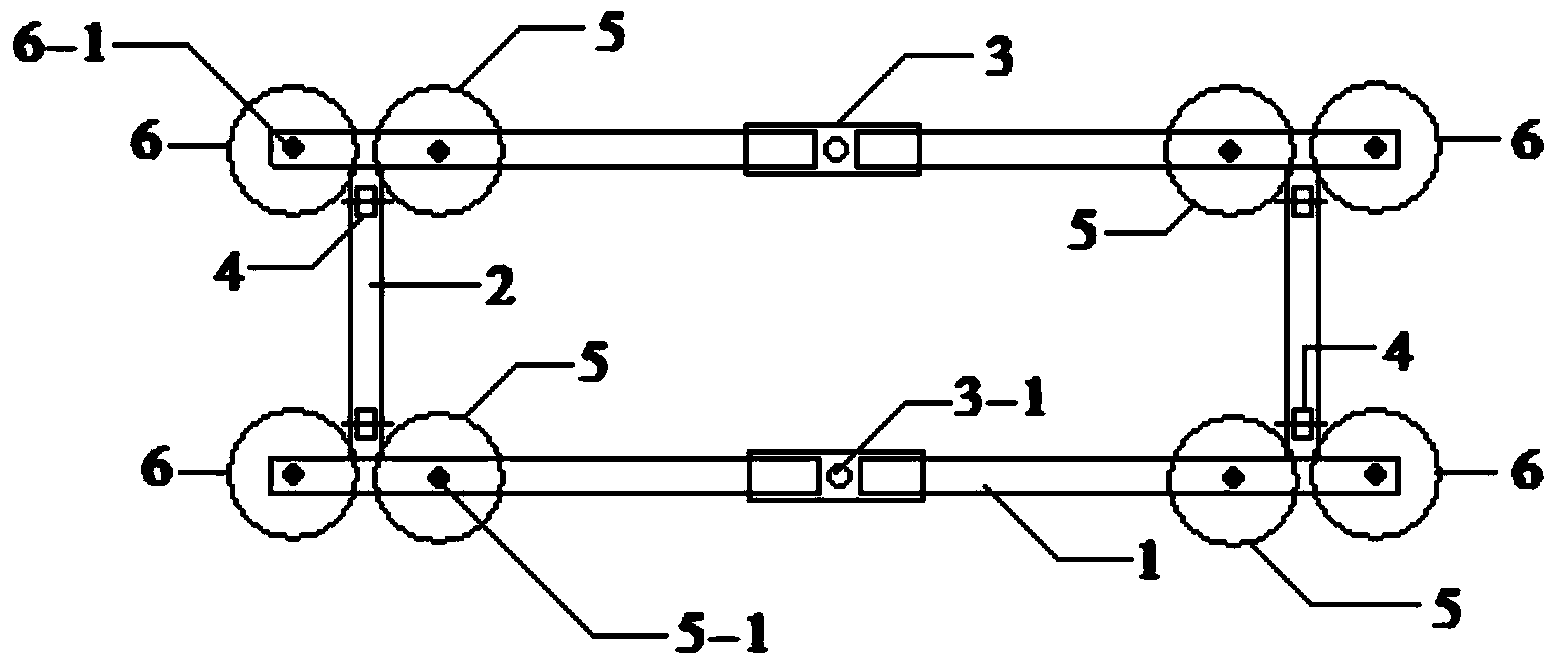

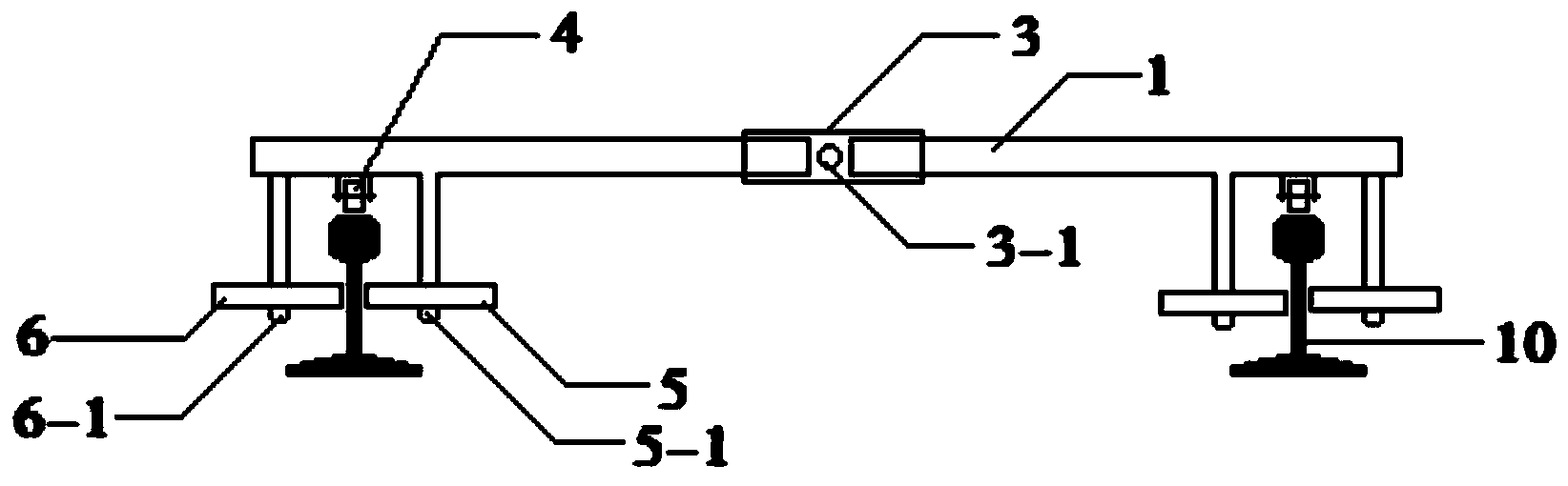

[0026] see figure 1 , figure 2 , a gauge correction device for double-block ballastless track construction, comprising two main girders 1, two sub-beams 2 parallel to each other are arranged at the two ends close to the main girders, and the main girders are connected in parallel to form Similar to the well-shaped layout; each main beam is equipped with a telescopic device in the middle to adjust the length of the main beam. Below each sub-beam, there are front and rear supporting running wheels 4 placed on the tool rail 10, and a pair of gauge correction wheels symmetrical to the sub-beam are arranged on the bottom near the end of the main beam through the wheel shaft, including placing them on the outside of the tool rail. The inner pull wheel 6 and the outer support wheel 5 placed on the inner side of the tool rail. The telescopic device can be composed of a telescopic sleeve 3 with positive and negative threaded bolts,

[0027] The main and auxiliary girders of the gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com