Accurate efficient adjusting device for machine tool assembly

A kind of machine tool and high-efficiency technology, applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems that affect the life of the screw and bearing, the transmission accuracy cannot meet the production requirements, and the composition and assembly structure are complicated, etc., to achieve Improve debugging accuracy, avoid abnormal wear and damage, and design reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

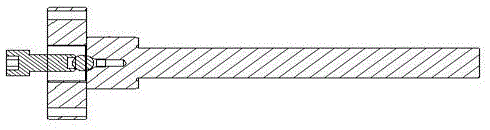

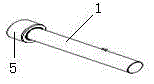

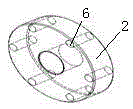

[0022] further as Figure 2 to Figure 6 As shown, firstly install the positioning snare 2 on the bearing seat to be installed of the drive part of the machine tool, then snap the first test rod 1 into the positioning snare 2, and then connect one end of the second test rod 3 to the first test rod 1 , one end of the positioning connecting column 7 is connected to the motor seat, and then the third test rod 4 is connected to the nut seat. Finally, the numerical information displayed by the centering lever table used in the test is relative to the bearing seat, the motor seat and the nut seat. Adjust the position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com