Wheel positioning measuring device

A technology for wheel positioning and measuring device, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of insufficient accuracy, narrow viewing angle, delayed processing speed, etc., and achieves the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

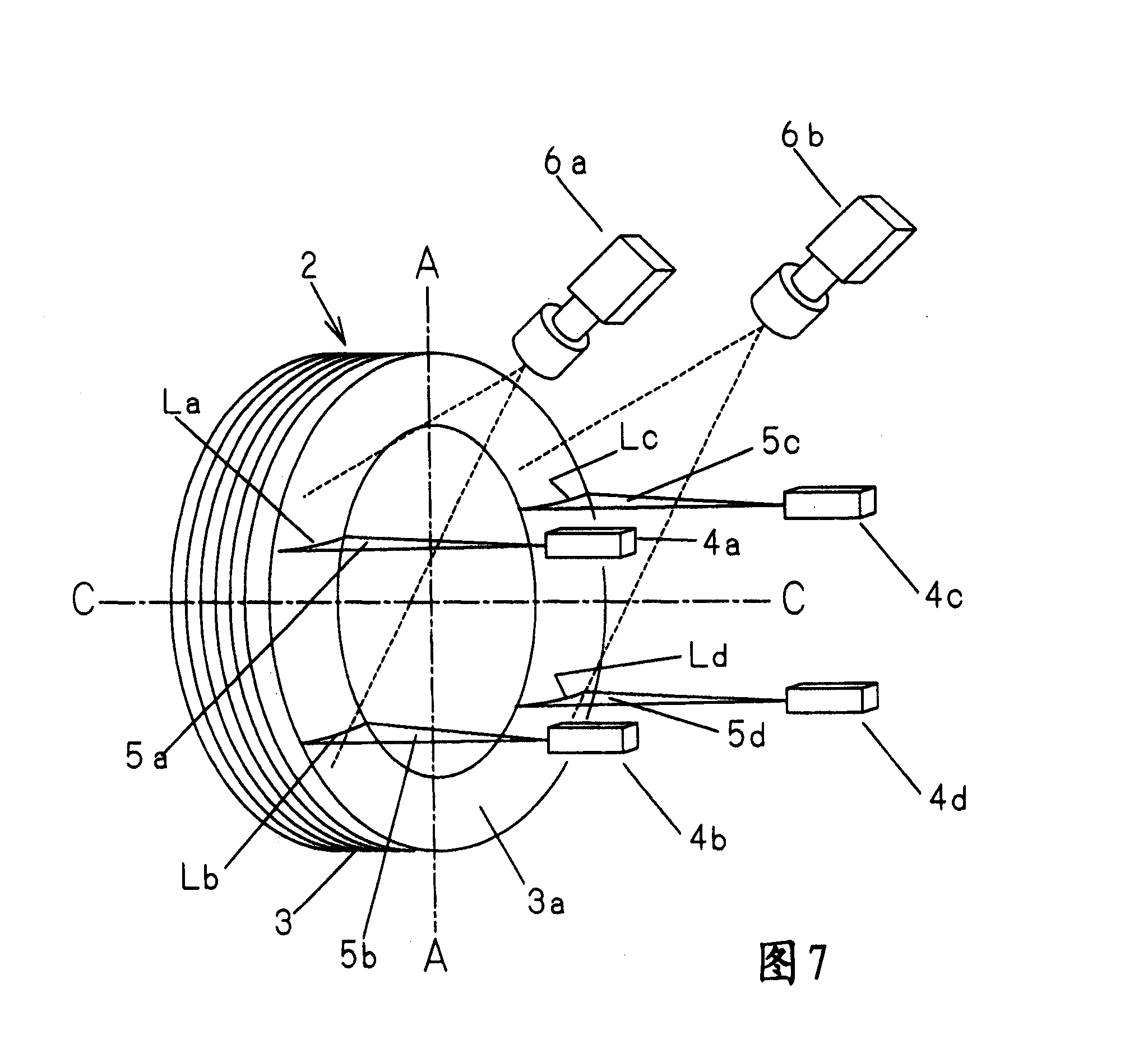

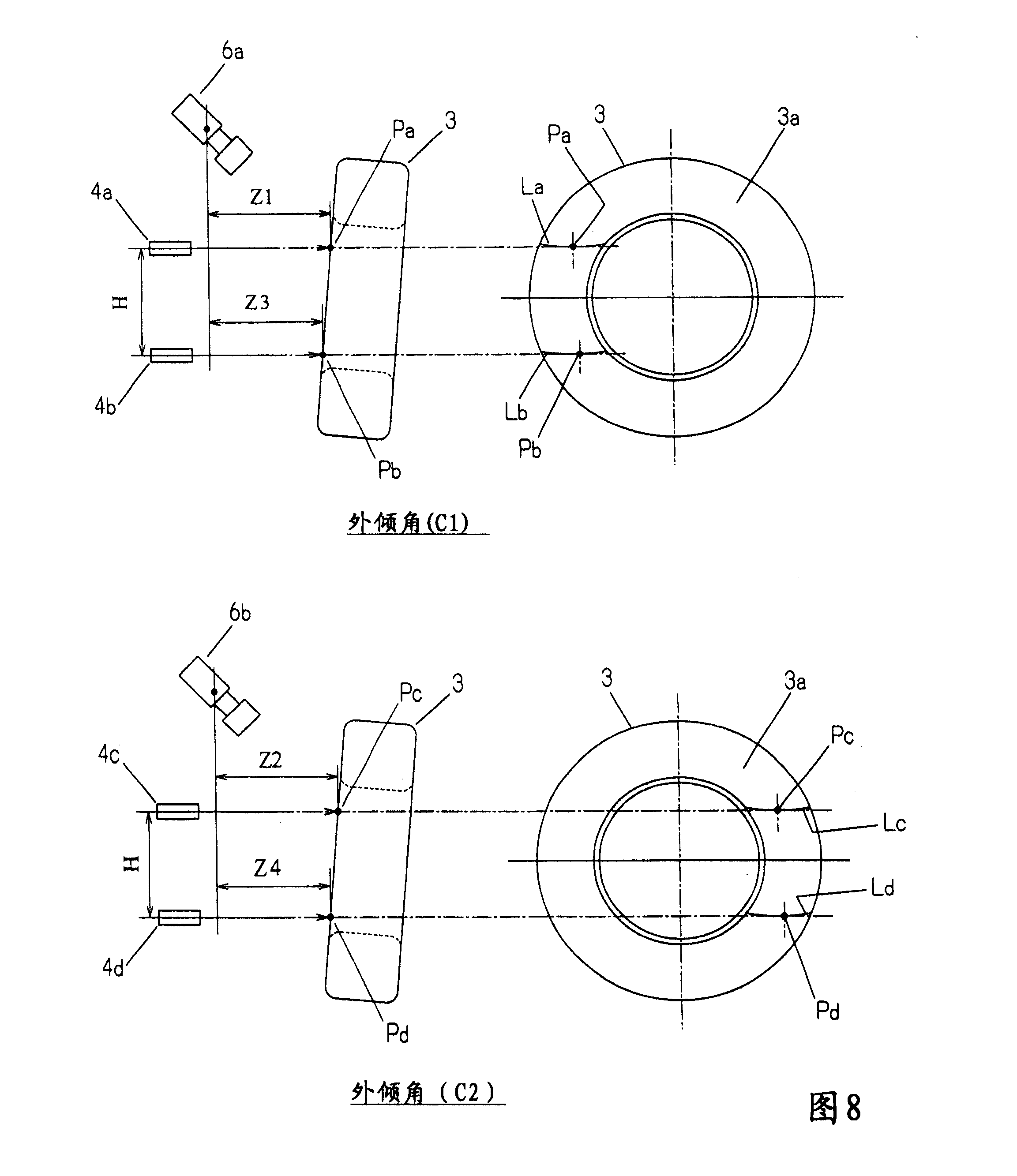

[0039] The wheel alignment measuring device of the present invention (hereinafter referred to simply as the measuring device) will be described with reference to the accompanying drawings.

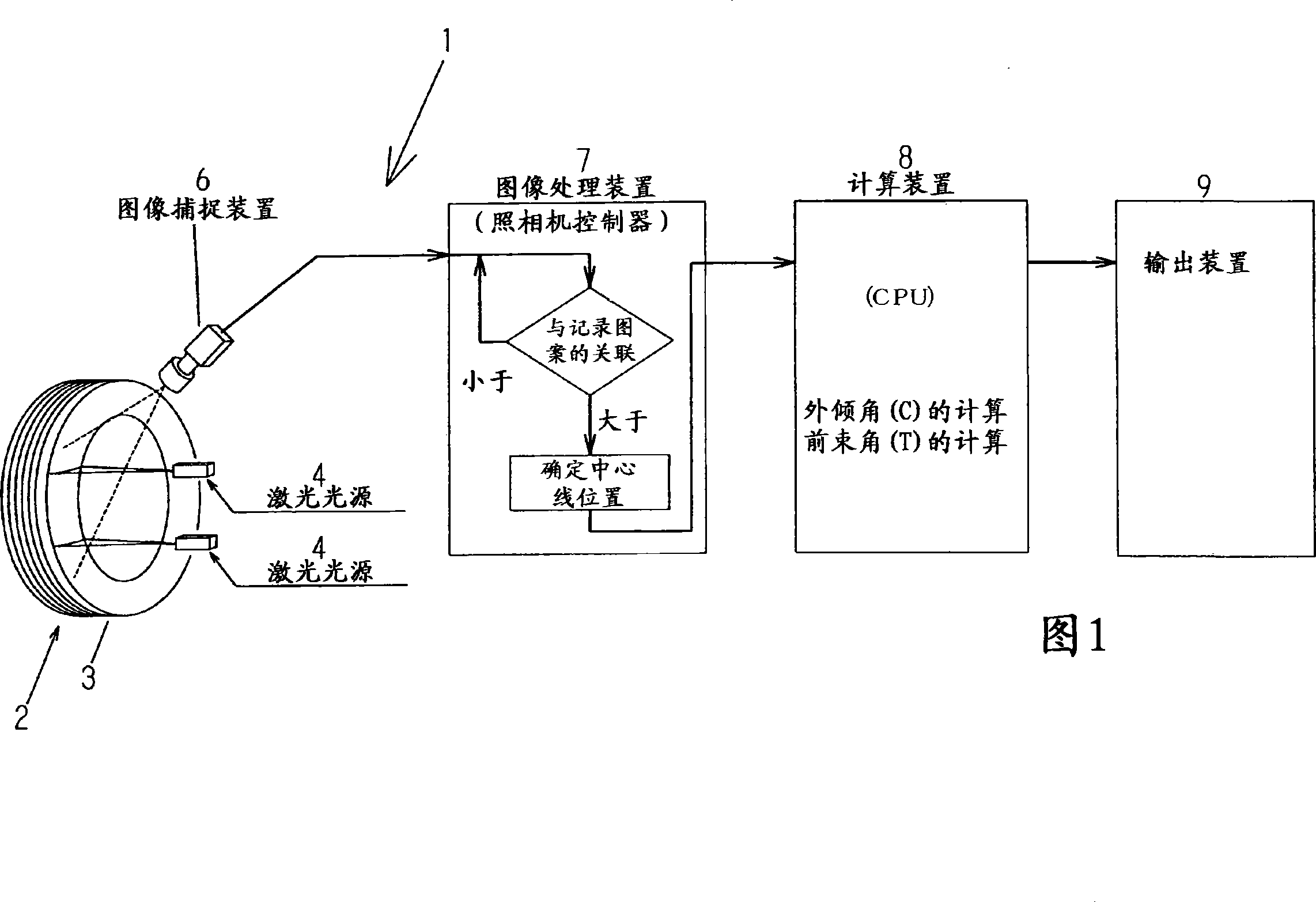

[0040] Figure 1 shows a block diagram of an embodiment of a measuring device. As shown in Figure 1, the measurement device 1 includes a pair of laser light sources 4 for emitting laser beams to the outside of the wheel to form an illuminated contour line thereon, and also includes an image capture device 6 for acquiring the contour line as a measurement image, and including image processing means 7 for determining and recording centerline position data of each contour line obtained by comparing the contour line of the captured image with a plurality of contour lines of the recorded image from the selected image, so as to select and capture the image therefrom The image with a certain or higher correlation also includes calculation means 8 for calculating the wheel alignment status on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com