Double-oil cylinder loaded ball screw assembly test bed

A technology of ball screw pair and ball screw, which is applied in the field of ball screw pair test bench, can solve the problem that the ball screw pair test bench cannot provide heavy-duty experimental conditions, etc., and achieve a wide range of load adjustment and system response speed Fast and wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

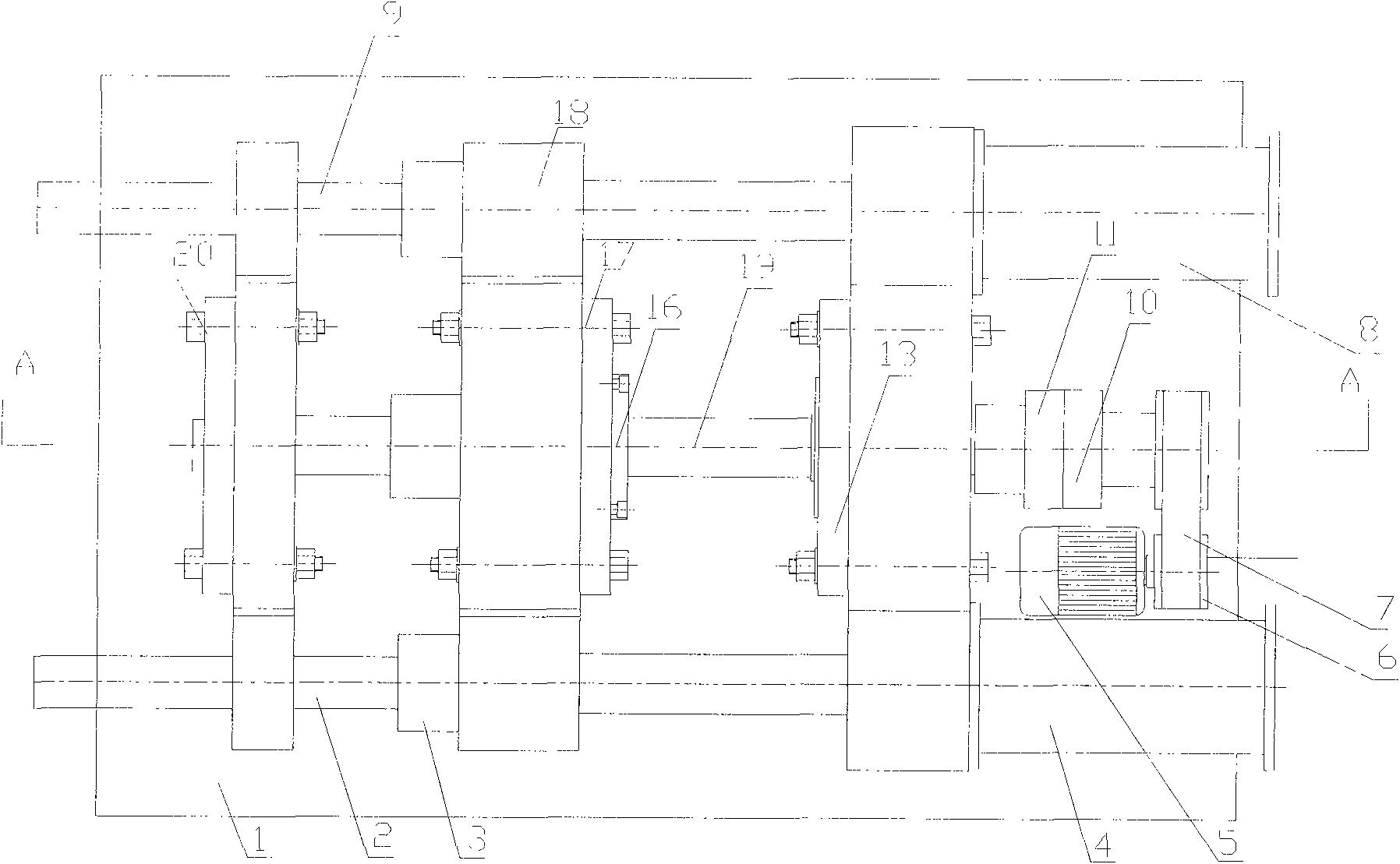

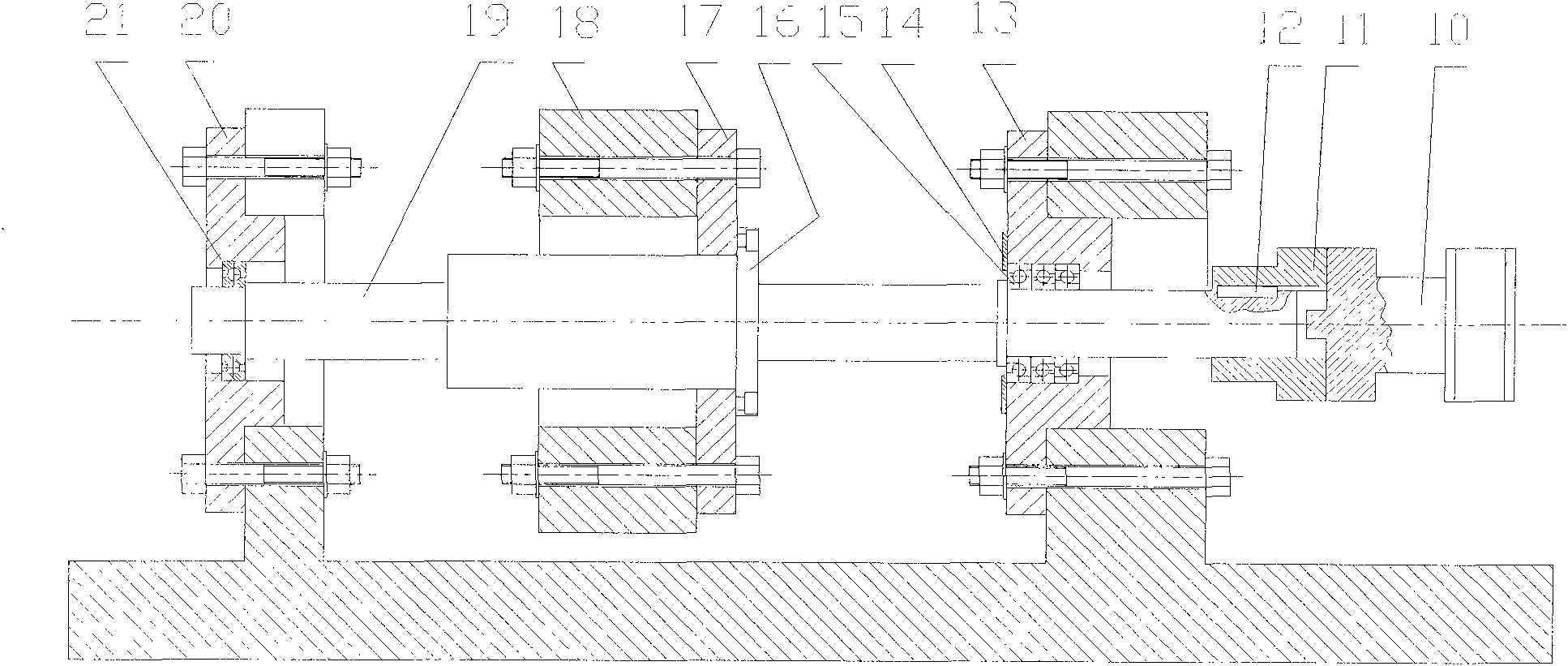

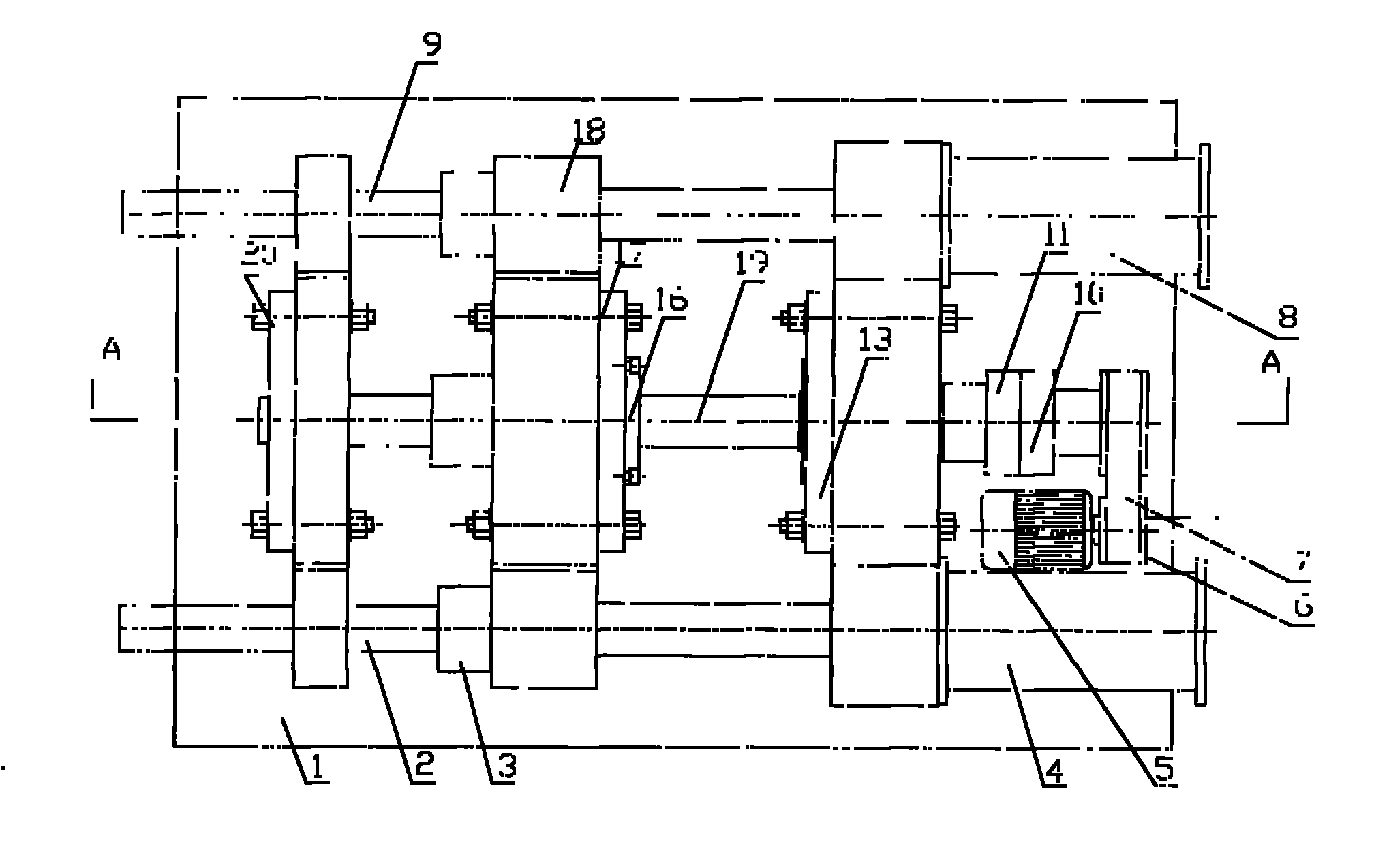

[0010] refer to figure 1 , figure 2 , the double hydraulic cylinder loaded ball screw auxiliary test bench of the present invention comprises a test bench base 1 on which two symmetrical hydraulic cylinders I 4 and hydraulic cylinders II 8 are fixed, and the two hydraulic cylinders have piston rods respectively I 2 and piston rod II 9, a ball screw 19 is installed at the symmetrical center of the two hydraulic cylinders, one end of the ball screw 19 is supported on the screw flange II 20 through a deep groove ball bearing 21, the ball screw 19 The other end is supported on the lead screw flange I 13 through the angular contact ball bearing 15. At the same time, this end is connected with the large pulley 10 through the key 12 and the coupling 11, and the large pulley 10 is connected with the servo motor through the synchronous belt 7. The small pulley 6 on the 5 is connected, the screw flange II 20 and the screw flange I 13 are fixed on the base 1, the ball screw 19 is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com