Method for positioning marine main engine foot bolt hole

A technology of foundation bolt holes and ship's main engine, which is applied to ship components, ship construction, ships, etc., can solve the problems of difficult to find deviations, the positioning deviation of the first footing bolt holes of the main engine, and increase the difficulty of positioning, etc., to achieve convenient management. , to ensure the quality of ship products, to ensure the effect of installation dimensional accuracy and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

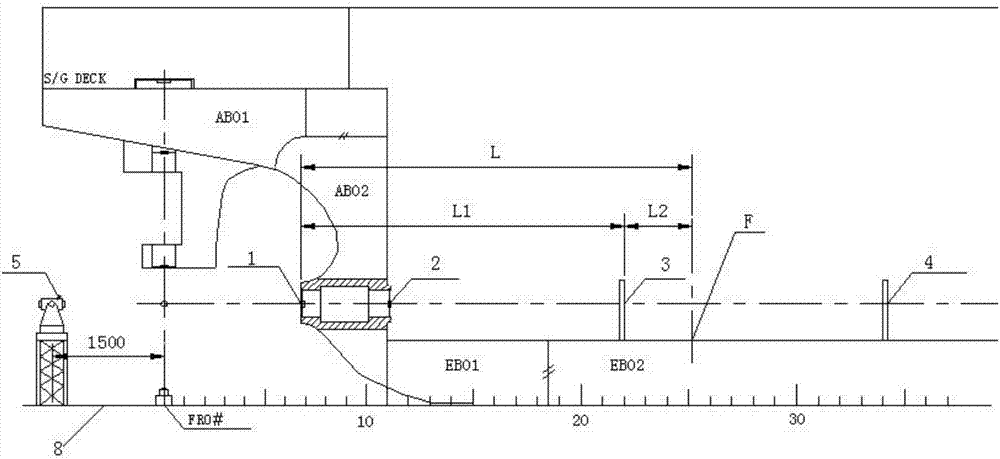

[0030] The practical application of the present invention will be specifically described below with the positioning steps of bolt holes of the main engine of a 76,000-ton bulk carrier.

[0031] The length of the shaft system in this embodiment is about 13.2m, the external dimensions of the main engine: 8700mm×7500mm×7700mm (length×width×height), the positioning accuracy of the main engine: axial -2~+5mm, lateral ±2mm.

[0032] Note: The units involved in the dimensions in the following steps are mm by default unless otherwise specified.

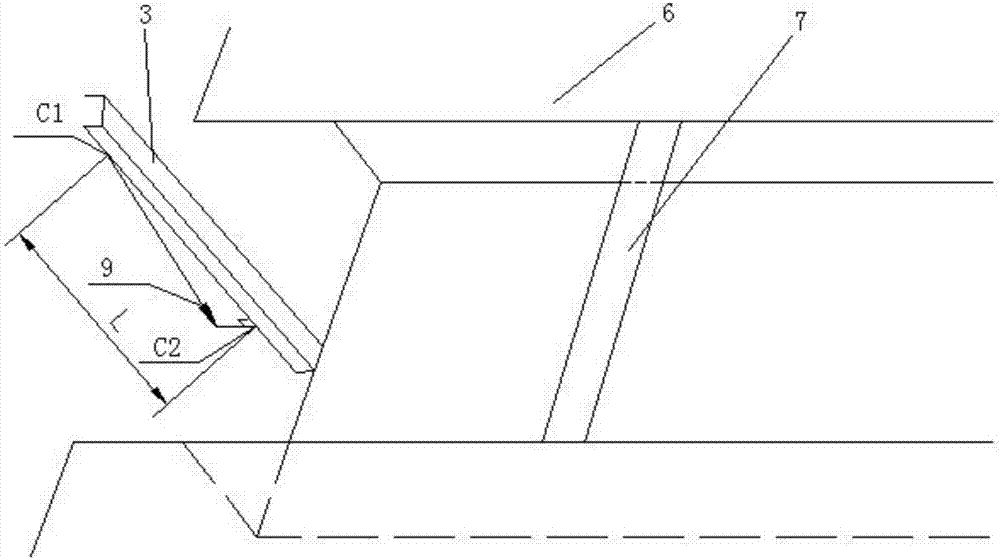

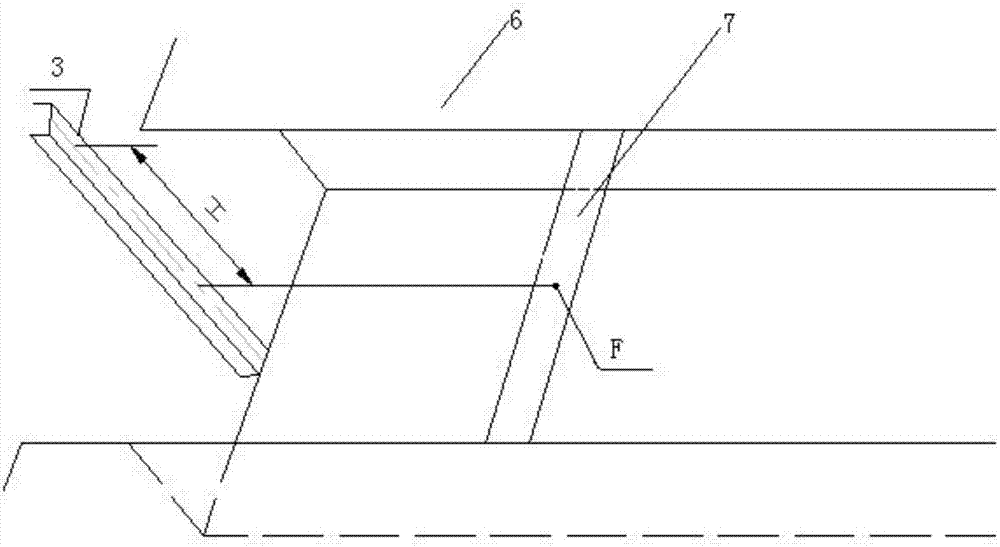

[0033] see Figure 1 to Figure 4 , the invention discloses a positioning method for anchor bolt holes of a ship main engine, which is characterized in that it comprises the following steps:

[0034] In the first step, a coring target A1 is placed on the rear end of the stern tube, a coring target B2 is placed on the front end of the stern tube, and the up, down, left, and right positions of the coring target A1 and the coring target B2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com