Manufacturing method of cross forging

A manufacturing method, cross-shaped technology, applied in the field of manufacturing special-shaped forgings, can solve the problems of unqualified sampling performance, increased production costs, unqualified flaw detection, etc., and achieve the effect of qualified sampling, tight internal structure, and qualified flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for manufacturing a cross-shaped forging, comprising the steps of:

[0022] a), pressing square: using a press to press out a square blank 1;

[0023] b), chamfering: use a press to press out chamfering at the four corners of the square blank 1;

[0024] c), indentation: place the round bar on the center line of the four chamfers of the blank 1, and then use a press to press out the circular groove;

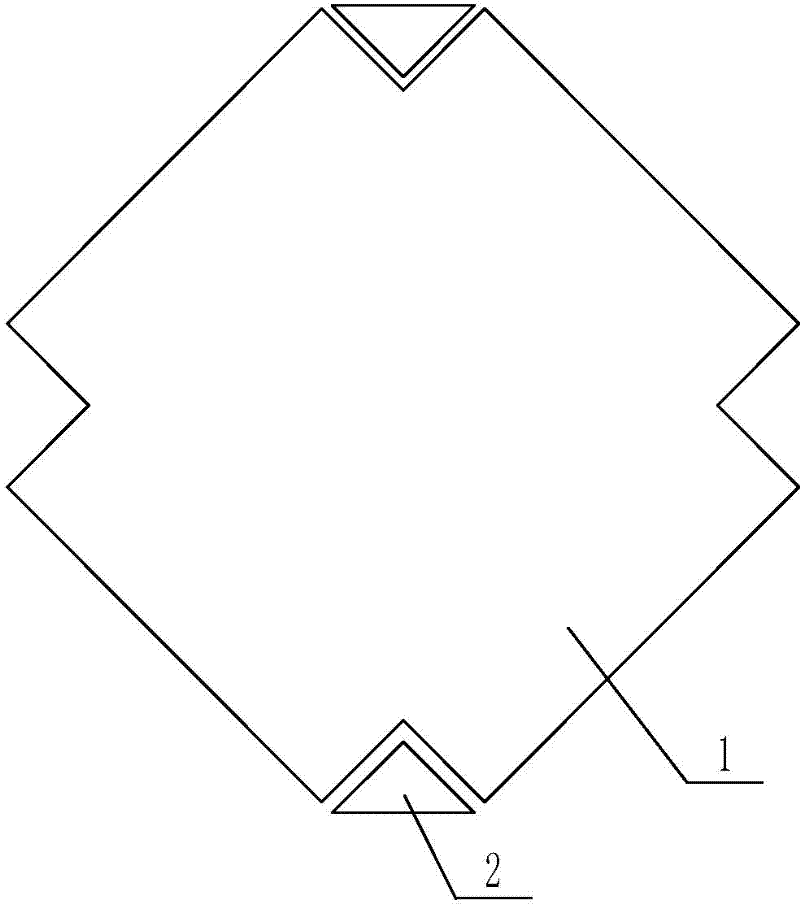

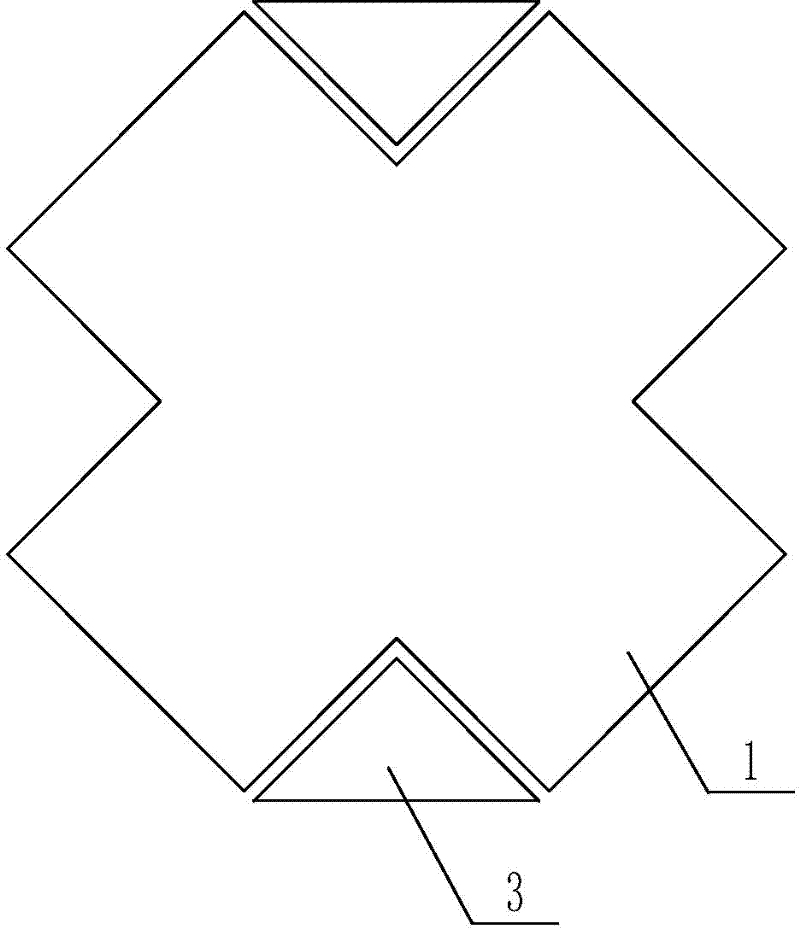

[0025] d), press the small angle: such as figure 2 As shown, using the small triangular knife 2, first align the blade of the small triangular knife 2 with the circular groove, and make the back of the small triangular knife 2 parallel to the chamfering surface of the blank, and then use a press to press the small triangular knife 2 to place Each chamfer of the blank 1 is respectively pressed with a small triangular groove, wherein the length of the right-angled side of the small triangular knife 2 is 0.08 of the length of the cross-shaped forging to be manufac...

Embodiment 2

[0031] A method for manufacturing a cross-shaped forging, comprising the steps of:

[0032] a), pressing square: using a press to press out a square blank 1;

[0033] b), chamfering: use a press to press out chamfering at the four corners of the square blank 1;

[0034] c), indentation: place the round bar on the center line of the four chamfers of the blank 1, and then use a press to press out the circular groove;

[0035] d), press the small angle: such as figure 2 As shown, using the small triangular knife 2, first align the blade of the small triangular knife 2 with the circular groove, and make the back of the small triangular knife 2 parallel to the chamfering surface of the blank, and then use a press to press the small triangular knife 2 to place Each chamfer of the blank 1 is respectively pressed with a small triangular groove, wherein the length of the right-angled side of the small triangular knife 2 is 0.12 of the length of the cross-shaped forging to be manufac...

Embodiment 3

[0041] A method for manufacturing a cross-shaped forging, comprising the steps of:

[0042] a), pressing square: using a press to press out a square blank 1;

[0043] b), chamfering: use a press to press out chamfering at the four corners of the square blank 1;

[0044] c), indentation: place the round bar on the center line of the four chamfers of the blank 1, and then use a press to press out the circular groove;

[0045] d), press the small angle: such as figure 2 As shown, using the small triangular knife 2, first align the blade of the small triangular knife 2 with the circular groove, and make the back of the small triangular knife 2 parallel to the chamfering surface of the blank, and then use a press to press the small triangular knife 2 to place Each chamfer of the blank 1 is respectively pressed with a small triangular groove, wherein the length of the right-angled side of the small triangular knife 2 is 0.10 of the length of the cross-shaped forging to be manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com