Single-screw metal screw pump stator and processing method for inner helical surface thereof

A single-screw, pump stator technology, applied to pump components, rotary piston type/oscillating piston type pump components, machines/engines, etc., can solve the problems of low inner hole precision, easy taper, poor rigidity, etc., to achieve improved Processing accuracy and processing efficiency, improve processing accuracy, and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

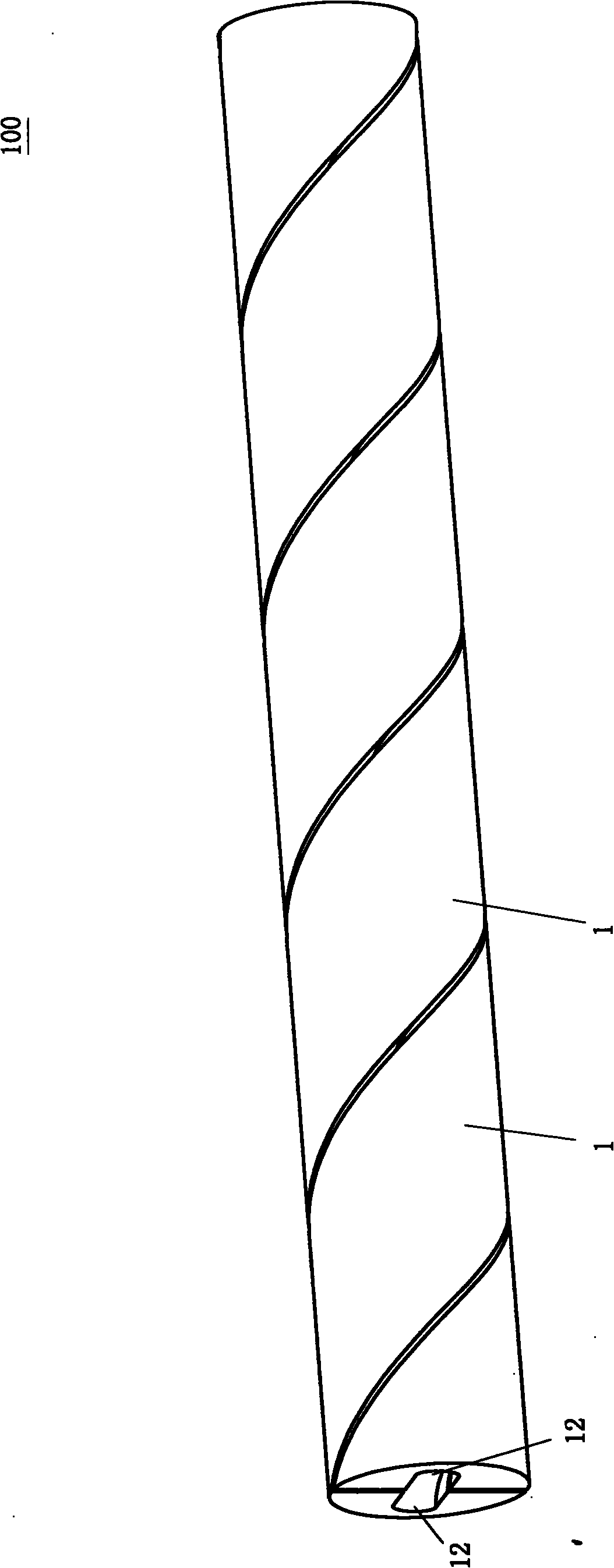

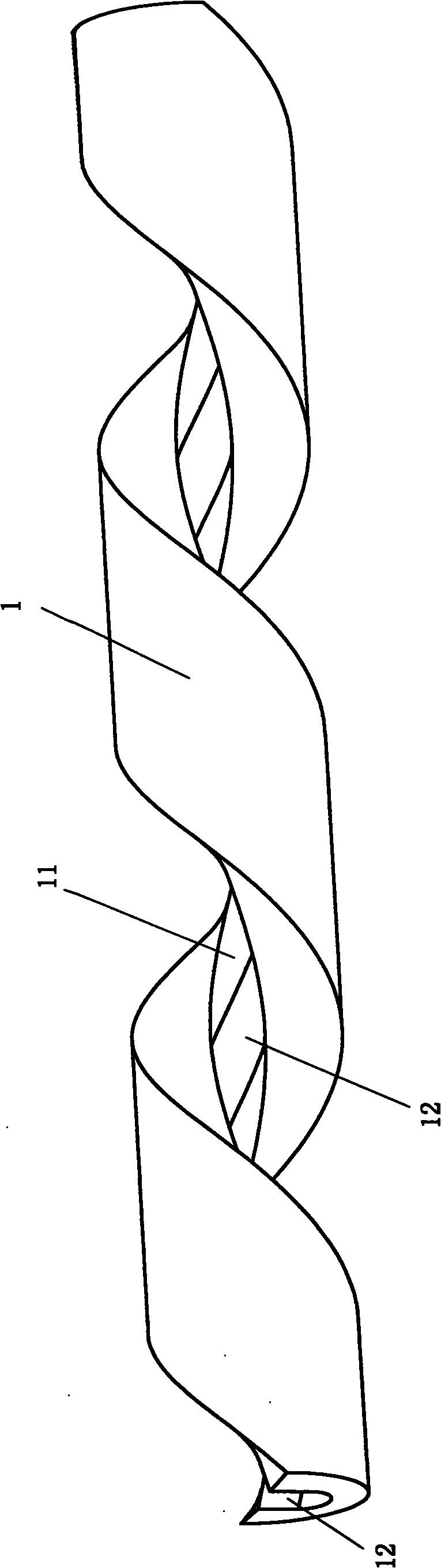

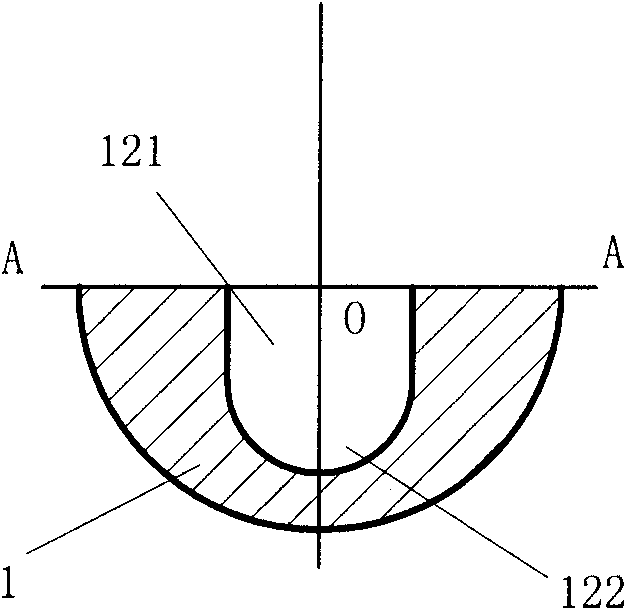

[0039] Such as figure 1 , figure 2 As shown, the present invention provides a single-screw metal screw pump stator 100. The stator 100 is composed of two helical bodies 1 with semicircular cross-sections that are correspondingly rotated and bonded. Surface; on each spiral body 1, be positioned at the centerline position of screwing surface (spiral surface) 11 and extend along this centerline and be provided with the groove 12 of a semicircular bottom, the cross section of described groove 12 (as image 3 As shown) is composed of a rectangle 121 and a semicircle 122 smoothly connected to the lower part of the rectangle. The grooves 12 of the two helicoids 1 are correspondingly screwed together to form the inner helical surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com