Integrated purification device for gaseous pollutants

A technology for purifying devices and pollutants, applied in combined devices, chemical instruments and methods, and separation of dispersed particles, can solve the problems of complex system structure, difficult maintenance, high operating costs, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

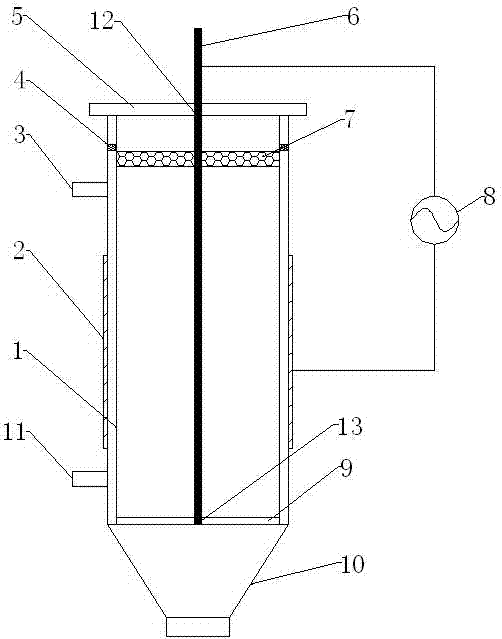

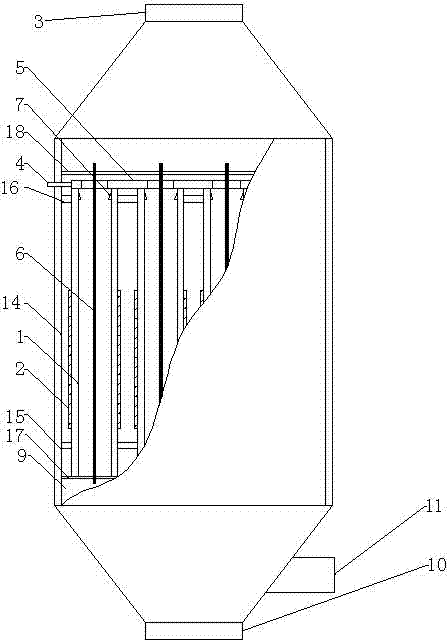

[0024] refer to figure 1 , an integrated purification device for gaseous pollutants, including a discharge reactor, the discharge reactor includes a reactor body 1, a high-voltage electrode 6, a ground electrode 2 and a high-frequency high-voltage power supply 8, and the reactor body is in the shape of a circular tube The corundum tube has an inner diameter of 4-40mm, a wall thickness of 1-5mm, and a length of 200-1000mm.

[0025] The lower part of the reactor body 1 is provided with an air inlet 11, and the upper part of the reactor body 1 is provided with an exhaust port 3; the high voltage electrode 6 is arranged at the longitudinal centerline of the reactor body 1, and the grounding electrode 2 is fixed on the reactor body On the shell; the high-voltage electrode is a stainless steel rod, which can effectively prevent the corrosion of acid gas; the diameter of the high-voltage electrode is 1-30mm, and the length is 250-1100mm. The ground electrode is a metal mesh, which i...

Embodiment 2

[0032] refer to figure 1 , an integrated purification device for gaseous pollutants, including a discharge reactor, the purification device is composed of a single discharge reactor, and the discharge reactor includes a reactor body 1, a high-voltage electrode 6, a ground electrode 2 and a high-frequency high-voltage power supply 8, The reactor body is a circular quartz glass tube with an inner diameter of 20 mm, a wall thickness of 2 mm, and a length of 750 mm.

[0033] The lower part of the reactor body 1 is provided with an air inlet 11, and the upper part of the reactor body 1 is provided with an exhaust port 3; the high voltage electrode 6 is arranged at the longitudinal centerline of the reactor body 1, and the grounding electrode 2 is fixed on the reactor body On the shell; the high-voltage electrode is a stainless steel rod, the diameter of the high-voltage electrode is 16mm, and the length is 900mm. The ground electrode is a metal strip, which is fixed on the shell o...

Embodiment 3

[0044] refer to figure 1 , an integrated purification device for gaseous pollutants, including a discharge reactor, the purification device is composed of a single discharge reactor, and the discharge reactor includes a reactor body 1, a high-voltage electrode 6, a ground electrode 2 and a high-frequency high-voltage power supply 8, The reactor body is a circular quartz glass tube with an inner diameter of 40 mm, a wall thickness of 5 mm, and a length of 1000 mm.

[0045] The reactor body 1 is a circular tube structure, and its upper part is closely connected with the head 5 . Its upper part has a circular tube exhaust port 3, the lower part has a circular tube air inlet 11, and its bottom is processed with a tapered drain port 10. The sealing head 5 is made of insulating material and is sealingly connected with the top end of the reactor body 1 . The absorption liquid enters the overflow tank 7 through the water inlet 4, flows along the inner wall of the reactor body 1 from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com