Patents

Literature

50results about How to "Easy to degrade naturally" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural fruit and vegetable cleaning fresh-keeping agent and sue method thereof

InactiveCN104611144AEfficient removalGrowth inhibitionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBiotechnologyFood grade

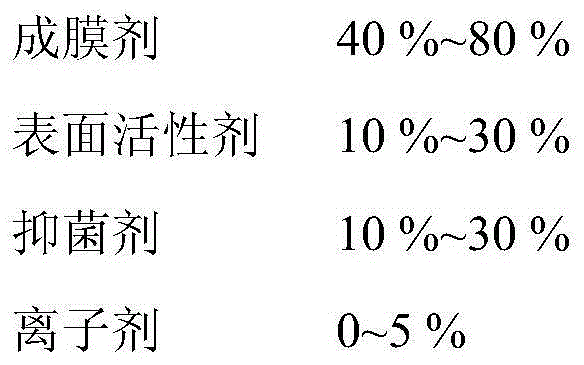

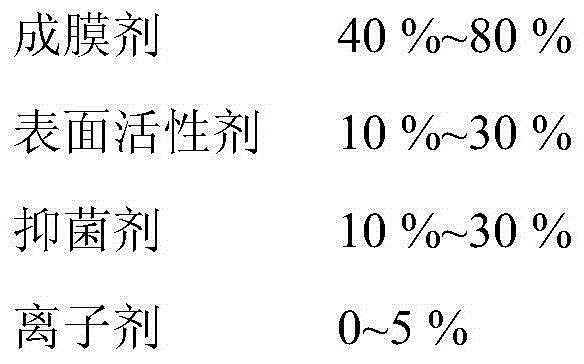

A natural fruit and vegetable cleaning fresh-keeping agent comprises a film forming agent, a surfactant, an antibacterial agent and an ionic agent, has both cleaning and fresh-keeping effect. The ingredients are natural food grade ingredients, harmless to human body, easy to naturally degrade, and strong in decontamination ability, after use, can effectively remove pesticide residues, heavy metals and other toxic substances on the surface of fruits and vegetables, can eliminate and inhibit the bacteria growth, also can from a film on the surface of the fruits and vegetables, and can prevent moisture loss and corruption to achieve the fresh-keeping effect.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Heat-resistance type transfer aluminum plated paper and its producing process

InactiveCN101050605AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveHeat resistance

The present invention relates to a temperature-resistant type transfer aluminized paper and its production process. Said process successively includes the following steps: coating release layer on the film; coating anchoring layer on release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer; then making them be combined with paper; stripping film from release layer so as to obtain the invented temperature-resistant type transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

Large-element water-soluble organic fertilizer and method for preparing same

InactiveCN102775230AImprove efficacyIncrease productionAgainst vector-borne diseasesFertilizer mixturesNutritionActive agent

The invention relates to a large-element water-soluble organic fertilizer and applications. The fertilizer is formed by compounding effective component extractives of sophora alopecuroides, sophora flavescens, toosendan fruit, euphorbia fischeriana and tobacco and reaction products of citric acid, tartaric acid and potassium hydroxide, and adding surface active agents, emulsifying agents, penetrating agents, cell activating agents, trace elements and the like. The novel fertilizer integrates both nutrition and plant protection functions. The novel multifunctional water-soluble organic fertilizer integrates insect killing, disease prevention and nutrition supplement, so that the fertilizer has both nutrient elements needed by crop health growth and insect killing and disease prevention functions.

Owner:北京睿中环保科技有限公司

Transfer aluminum plated paper and its producing process

InactiveCN101050606AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveBiochemical engineering

The present invention relates to a transfer aluminized paper and its production process. Said process includes the following steps: coating release layer on a film; coating anchoring layer on the release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer, then making them be combined with paper; stripping film from release layer so as to obtain the invented transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

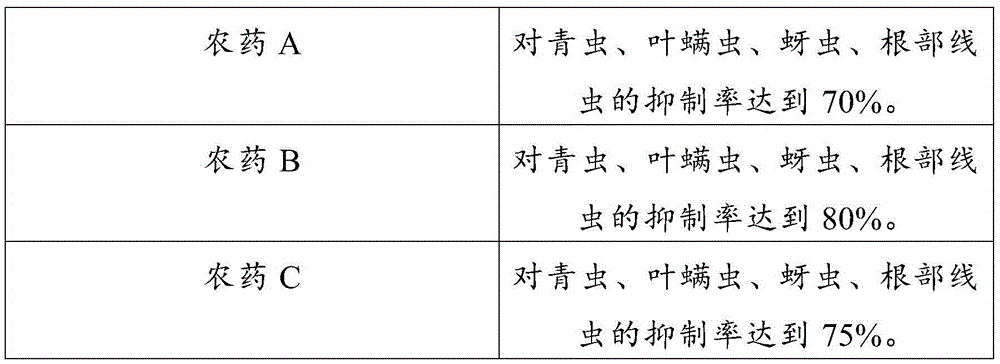

Preparation method of botanical insecticide

InactiveCN102057959ASafe and widely usedEasy to degrade naturallyBiocideAnimal repellantsNicotiana tabacumAlocasia

The invention relates to an insecticide and a preparation method thereof, particularly a botanical insecticide and a preparation method thereof. The insecticide is mainly prepared from the following Chinese herbal medicine protophyte extracts in percentage by weight: 50-75% of tobacco leftover, 2-5% of croton oil, 2-5% of Melia toosendan, 2-5% of wild chrysanthemum flower, 2-5% of pod pepper, 5-10% of arum, 5-10% of gingko exopleura and 5-10% of derris, wherein the tobacco leftover comprises the following components in percentage by weight: 64% of tobacco leaf, 18% of tobacco stem, 13% of tobacco root and 5% of tobacco flower. The invention has the following advantages: 1. the comprehensive insecticidal rate is high; 2. the application isolation period reaches about 15 days, thereby lowering the agricultural production cost; 3. no three wastes are produced in the production process, residues used as the fertilizer can be used for killing insects, the insect control rate for Chinese chive maggots is up to 95%, and the residues can also relieve sealing of soil and loosen the soil; and 4. no insecticide remains on crops.

Owner:高嵩

Botanical insecticide its preparation method

InactiveCN1539292AEasy to useEasy to degrade naturallyBiocideArthropodicidesMedicinal herbsChrysanthemum Flower

A vegetative insecticide is prepared from 8 Chinese-medicinal herbs including leftover of tobacco, Sichuan chinaberry, wild chrysanthemum flower, etc through carefully choosing raw materials, drying in air, pulverizing, immersing filter, steaming and concentrating. Its advantages are high effect, no environmental pollution, and improving soil.

Owner:李廷伦

Nanometer lubricant for drilling fluid and preparation method of nanometer lubricant

InactiveCN108753269AGood dispersionLarge specific surface areaMaterial nanotechnologyDrilling compositionWater in oil emulsionSURFACTANT BLEND

The invention discloses a nanometer lubricant for a drilling fluid and a preparation method of the nanometer lubricant in the petroleum industry. The lubricant is added to the drilling fluid to improve the lubricity of the drilling fluid, and then the friction and the torque in the drilling process are reduced. The nanometer lubricant for the drilling fluid comprises linear alpha-olefin, nanosilicon dioxide, sulfide fatty acid ester, a surfactant and water, the preparation method comprises putting the linear alpha-olefin into a stirring kettle, controlling the temperature of the kettle to 25-30 DEG C, then proportionally adding the surfactant, stirring for 4 hours, proportionally adding the nanosilicon dioxide, stirring for 2 hours, then proportionally adding the sulfide fatty acid ester,stirring for 2 hours, proportionally adding water, controlling the water addition speed to be lower than or equal to 2 m<3> / h, and continuously stirring for 4 hours until an even water-in-oil emulsionis formed, wherein the water-in-oil emulsion is the nanometer lubricant for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

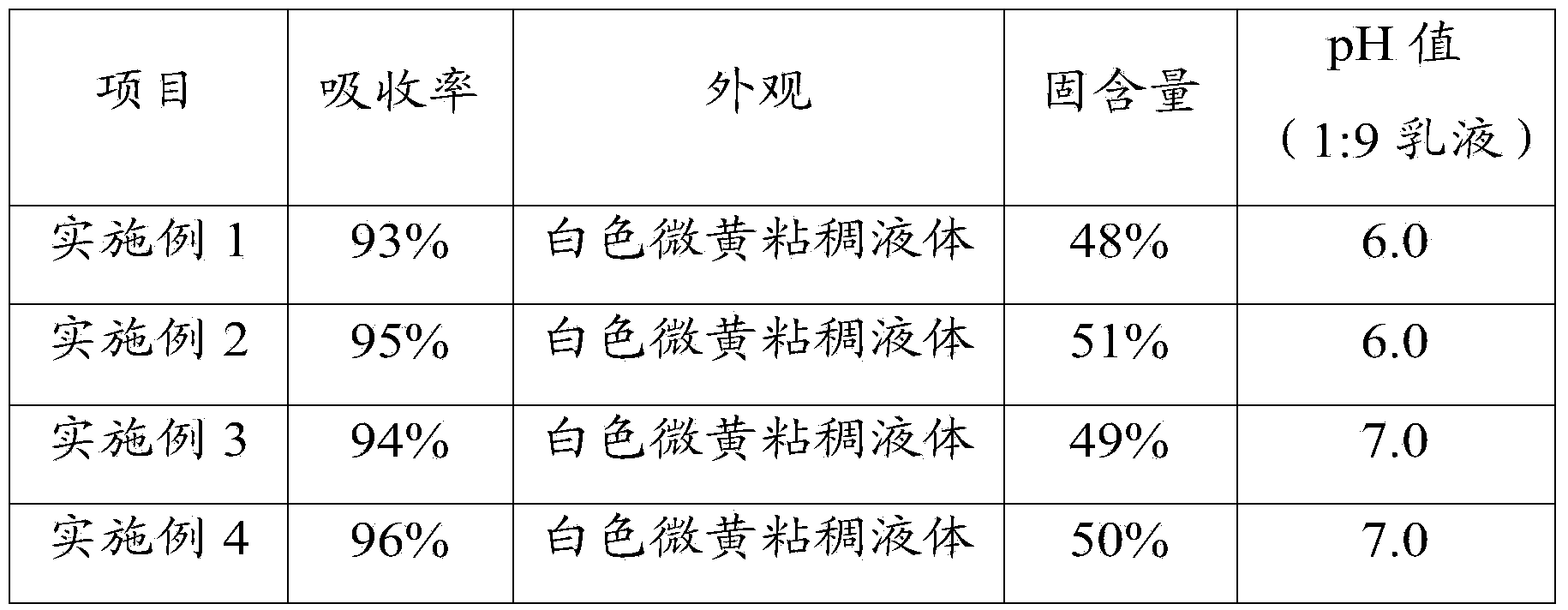

Double-face leather fatting agent and preparation method thereof

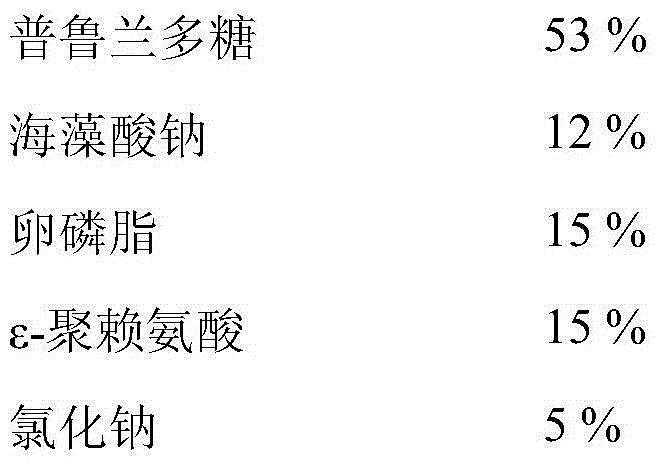

The invention provides a double-face leather fatting agent and a preparation method thereof, and belongs to the technical field of double-face leather processing. The double-face leather fatting agent comprises the following components in parts by weight: 70-85 parts of neutral oil and 15-30 parts of emulsifier, wherein the neutral oil comprises chlorinated alkane, epoxidized oil ester, higher aliphatic acid and higher aliphatic alcohol; the emulsifier comprises an ampholytic surfactant, a nonionic hydrophilic surfactant and a nonionic lipophilic surfactant. After the fatting agent provided by the invention is applied to the main oiling process of double-face leather, the absorptivity of the fatting agent can be up to 93-96%, the leather board is flexible, full, strong in forming sense, shallow in color and smooth and moist in hand feel, good fatting effect is provided, and the defect that the common fatting agents in the prior art are low in adsorptivity to cause waste and environment pollution is overcome.

Owner:BEIJING FANBO CHEM

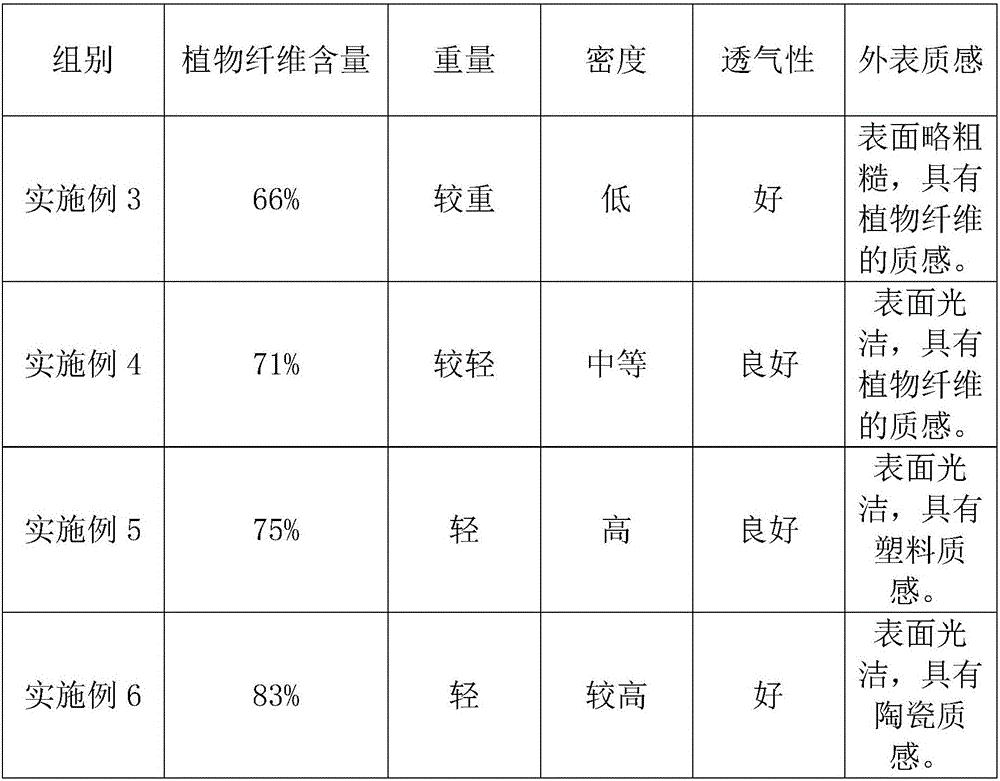

Method for preparing citrus peel-residue paper pulp mould

The invention discloses a method for preparing a citrus peel-residue paper pulp mould and belongs to the technical field of comprehensive utilization and processing of agricultural and sideline products. The method comprises the following steps of: preprocessing citrus peel-residue raw materials, rolling citrus peel-residues, degumming the products obtained by rolling the citrus peel-residues, mixing and molding of the products obtained by rolling the citrus peel-residues and the like. In the method, the citrus peel-residues which are byproducts of the processing of citrus are used as a raw material, the surface area, the cross linking degree and the tensile strength of the citrus fibers are improved after processing, and the problems of difficult forming and poor product quality are solved; and the prepared citrus peel-residue paper pulp mould product in a sheet shape or different mould shapes can be used for inner packaging of sugars, cakes and the like and outer packages of food, and the added value of the citrus peel-residues is improved. The method can be popularized and applied to food processing enterprises.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Biodegradable high-temperature-resistant disposable tableware and preparation method thereof

The invention provides biodegradable high-temperature-resistant disposable tableware and a preparation method thereof. The tableware is prepared from the following components: modified starch, glass fibers, PLA, PBAT, mineral powder, poly (butylene succinate), mica powder, polyolefin, sodium abietate, magnesium aluminum silicate, polyethylene glycol, a biodegradation accelerant, a compatilizer, a foaming agent, a nucleating agent, a surfactant, a dispersing agent and a coupling agent. The preparation method comprises the following steps: mixing the materials, adding into a mold, and carrying out hot press molding on the mold. The tableware has the beneficial effects that the tableware prepared by mixing the modified starch, the glass fibers, the PLA, the PBAT, the mineral powder, the poly (butylene succinate), the mica powder, the polyolefin, the sodium abietate, the magnesium aluminum silicate, the polyethylene glycol, the biodegradation accelerant, the compatilizer, the foaming agent, the nucleating agent, the surfactant, the dispersing agent and the coupling agent has a better degradation effect and higher high temperature resistance; and the material can be applied to high-temperature food and can effectively protect the ecological environment.

Owner:上海通原环保科技有限公司

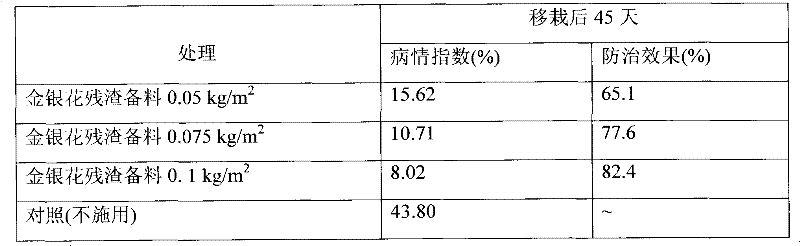

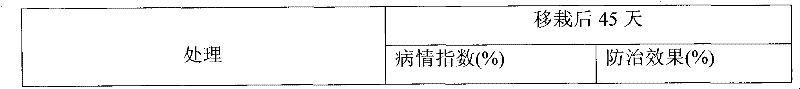

Application of honeysuckle residue to prevention and control of Dendranthema morifolium disease and insect

The invention aims at providing a method for preventing and controlling Dendranthema morifolium diseases and insects by using honeysuckle residues. The honeysuckle residues used in the method are prepared by using honeysuckles or branches and leaves of the honeysuckles through extraction or processing. The materials used in the method are easy to obtain, the cost is low, the implementation feasibility is strong and the efficiency of preventing and controlling the Dendranthema morifolium diseases and insects is high. The method has the advantages of environmental friendliness and high efficiency. Dendranthema morifolium cultivated by using the method has the advantages that the ability of resisting the diseases and the insects is strong, the Dendranthema morifolium is not apt to fall, the harvested Dendranthema morifolium flower bodies are full, the taste of industrially processed Dendranthema morifolium tea is very excellent and the quantity of pesticide residues is small according to determination.

Owner:湖北明钼健康科技有限公司

Biological pesticide

InactiveCN108835137AImprove insecticidal effectCompound synergistic effect is obviousBiocideAnimal repellantsCinnamomum camphoraVerbena

The invention relates to the technical field of pesticides, and discloses a biological pesticide. The biological pesticide includes, by weight, the following components: 18-24 parts of European verbena herb, 12-20 parts of ranunculaceae chrysanthemums, 14-17 parts of cinnamomum camphora, 6-13 parts of uniflower swisscentaury roots, 19-25 parts of inula flowers, 6-8 parts of boehmeria nivea oil, 5-12 parts of toosedarin, 5-12 parts of tea saponin, and 12-14 parts of dried ginger. The biological pesticide is strong and long-lasting in drug effect; residues of the biological pesticide on crops are easily naturally degraded by exposing to the sun and rain after usage of the biological pesticide; the biological pesticide is environmentally friendly; and the biological pesticide is not easy to be residual on the crops.

Owner:吴道华

Plant stain remover and preparation method thereof

InactiveCN109810790ALong shelf lifeIngredient safetyOrganic detergent compounding agentsSurface-active detergent compositionsChemistryAloin

The invention discloses a plant stain remover and a preparation method thereof. Based on the total weight of 100 parts, the plant stain remover is prepared from 2 to 5 parts of an aloe extracting solution, 10 to 20 parts of a fructus gleditsiae extracting solution, 15 to 20 parts of a cactus extracting solution, 0.1 to 0.5 part of potassium sorbate, 1 to 2 parts of borate, 1 to 6 parts of ethyleneglycol, 0.1 to 0.15 part of ethylenediamine tetraacetic acid and the balance of de-ionized water, wherein aloes and cactuses are fresh raw materials; the aloes and the cactuses are peeled off and then are used for preparing the extracting solutions. According to the stain remover, the fresh aloes and cactuses are used as direct raw materials for extraction; extract has good solubility in water and the problem that a co-solvent and a solubilizer need to be added is effectively overcome; the fresh aloes and cactuses are peeled to prevent the stability from being influenced by components under the peels and prevent the discoloring problem caused by washing of special fibers. The plant stain remover disclosed by the invention is used for industrial materials including metal, plastic and the like, and also has a good oil stain removing capability.

Owner:安徽省路兴建设项目管理有限公司 +3

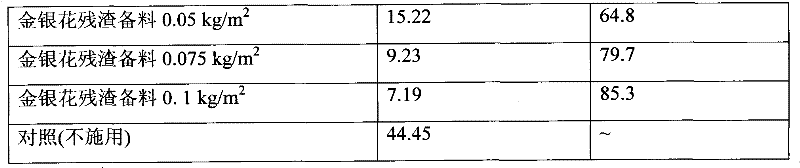

Low-energy-consumption soil organic pollutant in-situ treatment method and system

ActiveCN112547782AAvoid wastingReduce processing burdenContaminated soil reclamationMicroorganismSoil science

The invention relates to the technical field of restoration of contaminated soil, and discloses a low-energy-consumption soil organic pollutant in-situ treatment method and system. According to the method, most of organic pollutants easy to migrate are extracted through heat strengthening, and then chemical fluids such as an oxidizing agent and alkali liquor are injected for thermochemical degradation so as to treat residual low-concentration organic pollutants; and finally, a microbial nutrient solution is injected in the cooling stage to enable organic pollutant degrading bacteria to becomedominant species in the contaminated soil so as to further consolidate the treatment effect. Various different pollutant treatment modes are effectively coupled together, the advantages of various treatment modes are fully utilized, each pollutant treatment mode has a beneficial effect on the next pollutant treatment mode, and the energy consumption for treating organic pollutants in soil is effectively reduced on the premise that the same or even better treatment effect is achieved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

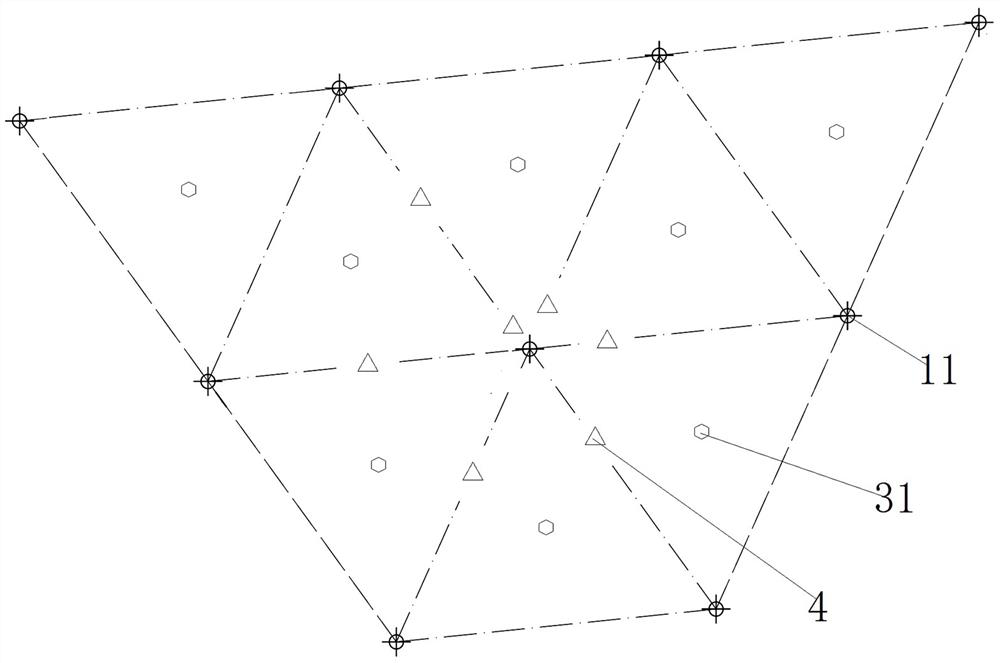

Pesticide applied through unmanned aerial vehicle and preparation method thereof

ActiveCN105454224AIncrease loading capacityReduce the number of repeated take-off and landing dosingBiocideDead animal preservationInternal pressureUncrewed vehicle

The invention belongs to the technical field of pesticides, and relates to a pesticide applied through an unmanned aerial vehicle. The pesticide is prepared from water-soluble film, gas and a gel composition; the water-soluble film forms a sealed capsule body which is filled with the gel composition and the gas, and the internal pressure of the capsule body is greater than the external pressure of the capsule body. The invention further relates to a preparation method of the pesticide. When the pesticide is used, the loading capacity of one-time effective components of the unmanned aerial vehicle is large, and the frequencies of repeated pesticide adding are reduced; pesticide spraying is completed by means of the spray force of the pesticide in the capsule body, the unmanned aerial vehicle does not need to conduct large-area spraying, the effect can be achieved by only putting the pesticide on multiple points, and the operation efficiency is improved.

Owner:创客帮(山东)科技服务有限公司

Plant composite fiber, plant fiber composite and preparation method of plant fiber composite

The invention belongs to the field of new materials and provides a plant composite fiber, a plant fiber composite and a preparation method of the plant fiber composite. The plant composite fiber is mainly prepared from plant fiber and low-melting-point polyester fiber through mixing with a spunlace or needle punching technology, wherein the melting point of the low-melting-point polyester fiber is 60-200 DEG C. The plant fiber composite has the advantages of being high in strength, low in weight, stable in physical performance, not easy to damage, capable of being recycled and the like. The plant fiber composite prepared from the plant fiber composite has the advantages that the surface texture is natural and plain, the color is bright, the texture is novel, adhesives are not contained, recycling is realized and the like. The plant fiber composite can be widely applied to fields such as packaging products, artware, daily necessities and the like.

Owner:江苏昕飞扬工艺有限公司

Detergent and method for preparing same

InactiveCN106987399AReduce dosageReduce pollutionNon-ionic surface-active compoundsDetergent perfumesMildewSolanum tuberosum

The invention discloses a detergent and a method for preparing the same. The detergent is mainly made of raw materials including, by weight, 40-60 parts of potato peel extract liquid, 10-30 parts of tea saponin, 5-20 parts of tea polyphenols, 1-10 parts of eleocharis tuberosa peel and herba taraxaci extract liquid and 0.5-2.5 parts of thickening agents. The method includes raw material treating, mixing, gelatin cooking and blending so as to obtain the finished detergent. The detergent and the method have the advantages that the detergent is mainly made of agricultural and sideline waste, accordingly, waste can be turned into wealth, and resources can be comprehensively utilized; excellent washing effects of the detergent can be realized by the aid of the tea saponin and potato peel extract among the raw materials; excellent antibacterial, mildew-proof and disinfection effects and the like of the detergent can be realized by the aid of the tea polyphenols and eleocharis tuberosa peel and herba taraxaci extract.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

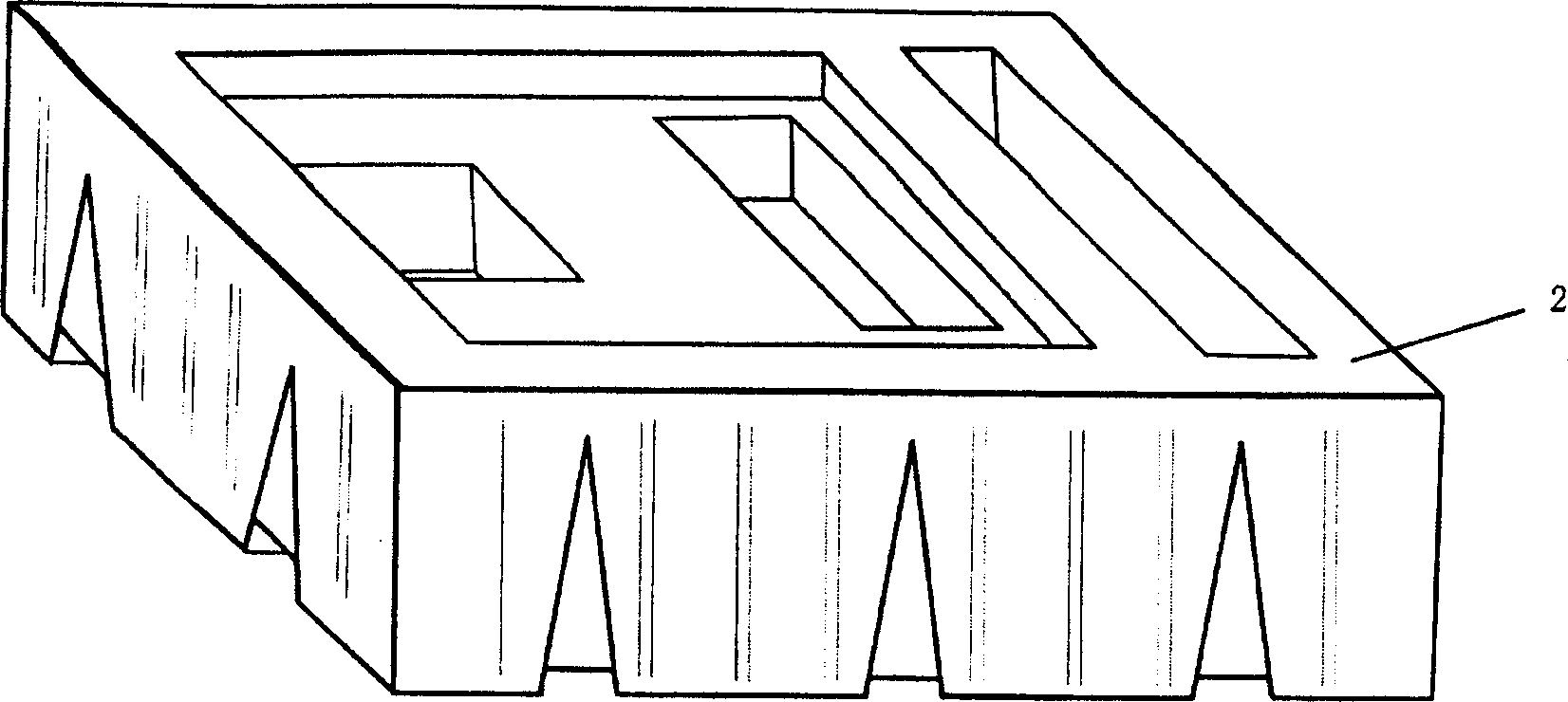

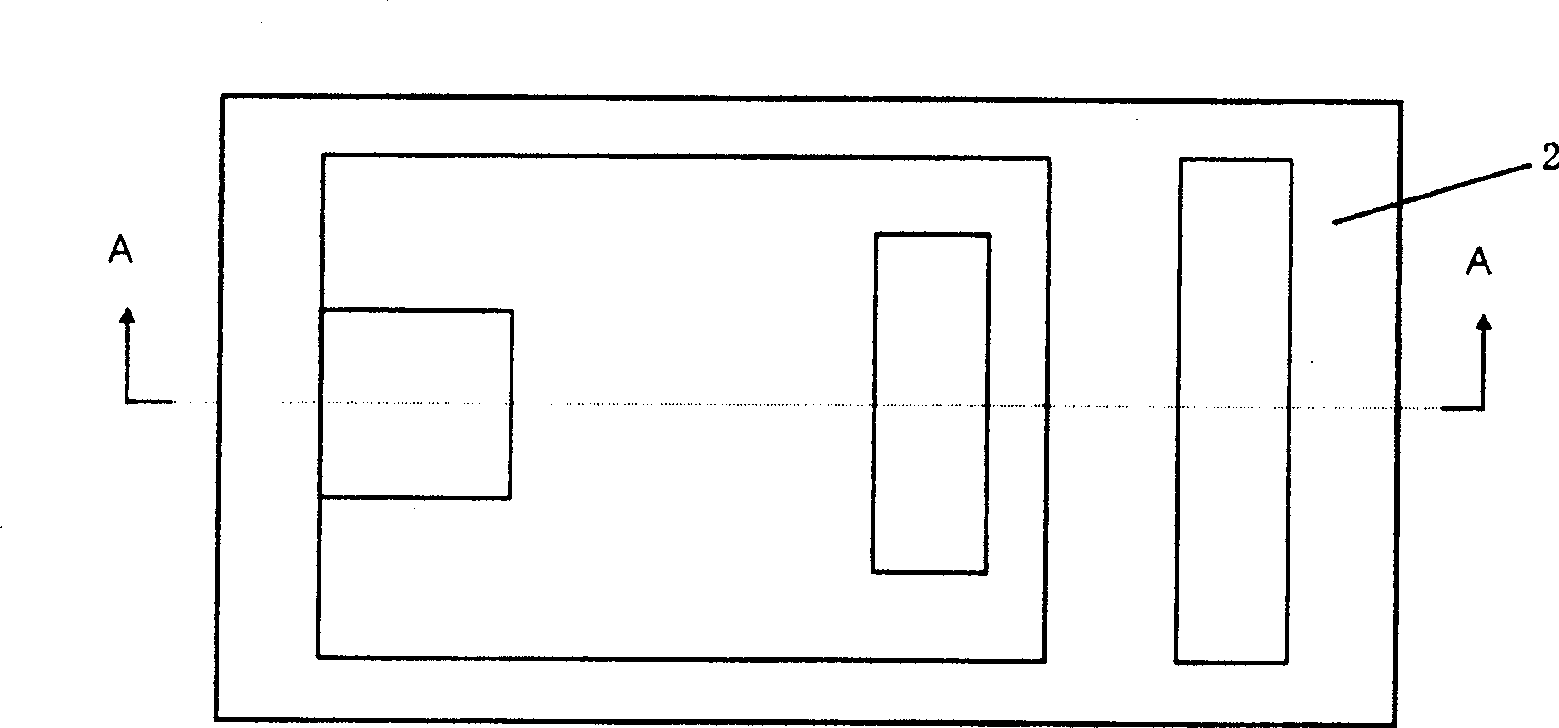

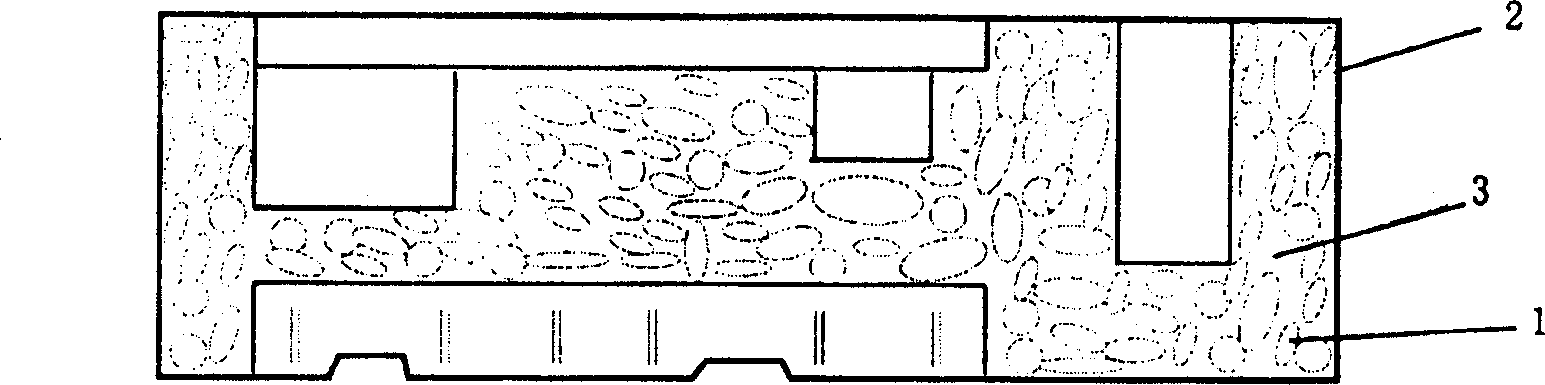

Technology for making buffer with straw or stalk as main raw material

InactiveCN1140438CThe surface of the product is smoothThe product surface is beautifulFlexible coversWrappersWaddingEngineering

A vibration-damping buffer as packing material is made up through making hollow thin-wall shell with paper or plastics, filling the straw or stalk in its internal cavity, and adhering. Its advantages are easy degradation and treating.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

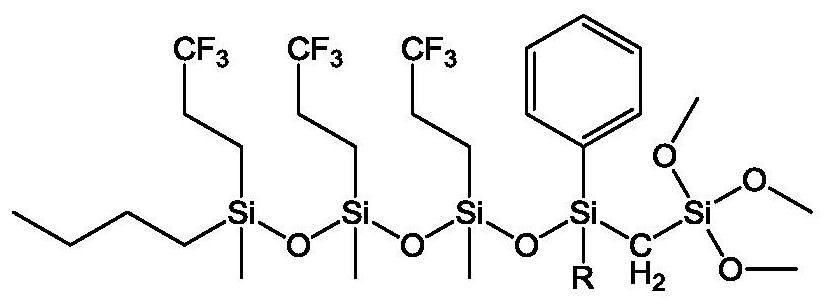

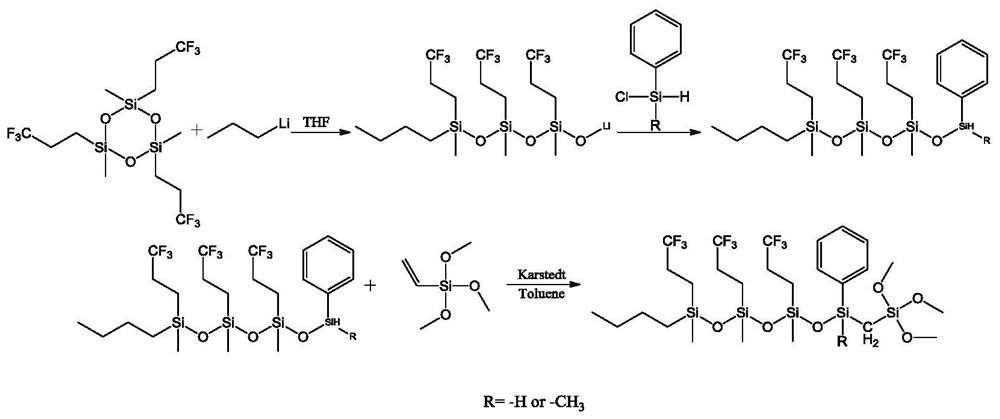

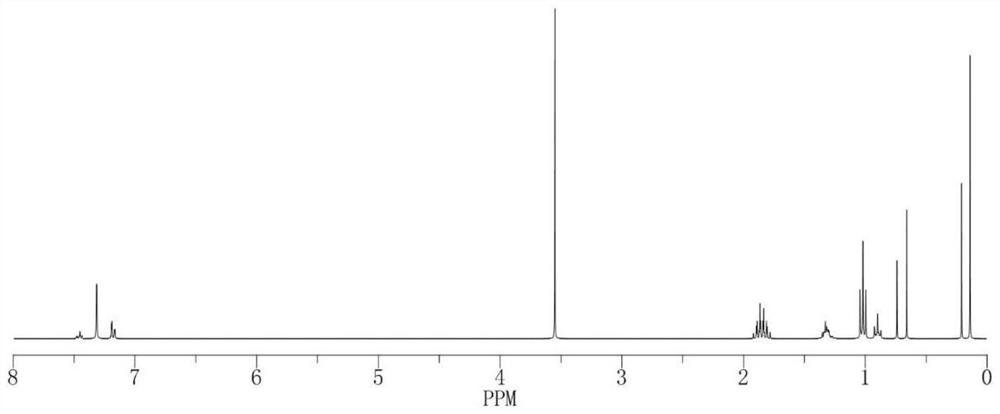

Preparation method of modified polyurethane sealant

InactiveCN112375531AEasy to degrade naturallyWill not bioaccumulateGroup 4/14 element organic compoundsPolyureas/polyurethane adhesivesEndcappingPolymer science

The invention relates to the technical field of polyurethane sealants, in particular to a preparation method of a modified polyurethane sealant, which comprises the following steps of: reacting polyether polyol with polyisocyanate, a first catalyst and a first plasticizer until the NCO% reaches 3-5%, adding a fluorine-containing silane coupling agent, and terminating to obtain a polyurethane prepolymer; and fully mixing the polyurethane prepolymer, a second plasticizer, a filler, a water removal agent, an antioxidant and a second catalyst under a vacuum condition to obtain the single-componentmodified polyurethane sealant. The poor corrosion resistance of the traditional polyurethane sealant is overcome, and the modified polyurethane sealant with excellent corrosion resistance, especiallyalkali resistance, is provided.

Owner:杭州鹿扬科技有限公司

Neutral remover of high temperature oxide skin and preparation method thereof

The invention discloses a neutral remover of high temperature oxide skin and a preparation method thereof. The neutral remover of the high temperature oxide skin consists of components of 5-9 parts ofacetylenic alcohol, 9-12 parts of plant surface activity dispersant, 10-18 parts of reductant, 17-34 parts of chelating agent, 2-3 parts of PH (potential of hydrogen) modifier and the balance deionized water. An extracting solution is prepared after removing skin of aloe gel in the plant surface activity dispersant. In preparation of the neutral remover of the high temperature oxide skin, the basic sequence of firstly adding solid, secondly adding liquid, and finally adding the reductant and solution having blistering effect is adopted for mixing all the components, and acid and alkali are dripped in the mixed components for adjusting PH value to 6.5-7.5. The remover is neutral, can completely replace modes of sand blasting, strong acid and alkali washing and the like for removing the black oxide skin, cannot cause a hydrogen permeation phenomenon or excessive corrosion to a base material, and keeps original mechanical performance of the base material. Under the synergistic effect ofthe acetylenic alcohol, the plant surface activity dispersant, the reductant and the chelating agent, the neutral remover of the high temperature oxide skin has the effects of being high in removal speed and thorough in removal. Waste liquid of the neutral remover of the high temperature oxide skin is environment friendly, and the neutral remover of the high temperature oxide skin cannot cause health or safety hazards to operation staff when used, and meanwhile can effectively recycle mono-metal powder.

Owner:阜阳市安能工程检测有限公司 +2

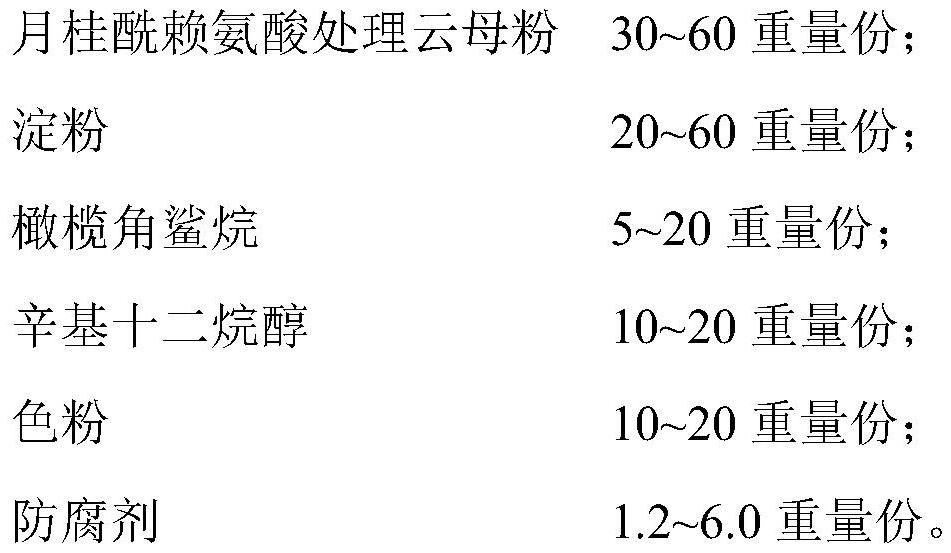

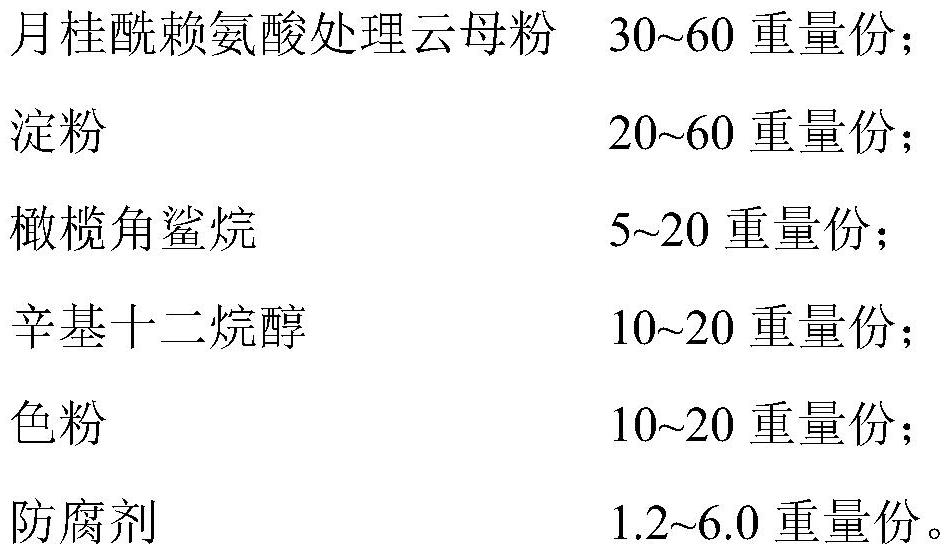

Environmental-friendly powder-baking compact powder and preparation method thereof

PendingCN111773135AGood senseExcellent physical and chemical indicatorsCosmetic preparationsBody powdersOrganolepticLysine

The invention relates to the field of color make-up cosmetics, and particularly discloses environmental-friendly powder-baking compact powder and a preparation method thereof. The environmental-friendly powder-baking compact powder comprises the following components of 30-60 parts by weight of mica powder treated with N-lauroyl-L-lysine, 20-60 parts by weight of starch, 5-20 parts by weight of olive squalane, 10-20 parts by weight of octyldodecanol, 10-20 parts by weight of toners and 1.2-6.0 parts by weight of preservatives. According to the environmental-friendly powder-baking compact powderdisclosed by the invention, various raw materials having organic authentication are used in the formula of the environmental-friendly powder-baking compact powder, and raw materials of talcum powder,silicone oil, silicon powder, TiO2, nylon powder, PMMA, synthetized fat and the like are not used, so that the prepared powder-baking compact powder has excellent sense organ indexes and excellent physical and chemical indexes, and also has the advantages of being high in ultraviolet ray resistant capacity, environmental-friendly, pollution-free, easy to naturally degrade and the like. In addition, the preparation method is simple and quick to operate and high in efficiency.

Owner:上海市天乐日化厂

Preparation method for cellulose carbamate fiber tow for cigarette

ActiveCN103233290AGood chemical adsorptionImprove filtering effectTobacco smoke filtersArtificial filaments from cellulose derivativesCarbamateCellulose acetate

The present invention provides a preparation method for cellulose carbamate fiber tow for cigarette. According to the method, cellulose carbamate with a viscosity-average molecular weight of 48000-100,000 and a nitrogen content of 0.1wt%-7.0wt% is dissolved in a mixed aqueous solution of sodium hydroxide and zinc oxide to give a spinning solution with a certain concentration; and by using a wet spinning technique for spinning, and a mixed solution of sulfuric acid, sodium sulphate and zinc sulphate as a regeneration bath, the cellulose carbamate fiber tow for cigarette is obtained from the spinning solution through several processes of spinning -spinning oil applying- drafting- crimping-drying. The filter rod produced by using the tow of the invention has obvious filtering effect on harmful substances in smoke, and can be used in cigarette to replace cellulose acetate fiber tow and acrylic fiber tow.

Owner:HUBEI TIANSI TECH

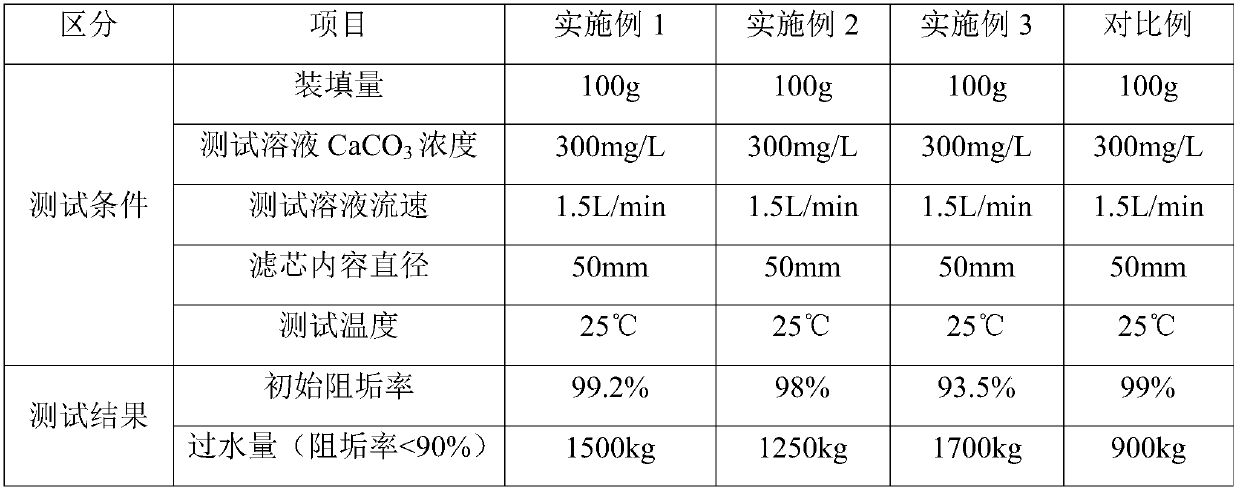

Sustained-release scale inhibitor and preparation method thereof

InactiveCN109592801AEasy to degrade naturallyWell formedSpecific water treatment objectivesScale removal and water softeningCarboxylateBiological body

The invention relates to a sustained-release scale inhibitor and a preparation method thereof, and belongs to the technical field of water treatment. The sustained-release scale inhibitor is preparedfrom the following raw materials in parts by weight: 5-15 parts of poly-histidine, 3-10 parts of hydroxy-carboxylate, 50-80 parts of kaolin, 20-40 parts of microporous minerals and 3-5 parts of waterinsoluble adhesive. The sustained-release scale inhibitor is scientific and reasonable in formula design and good in biodegradability, can be quickly degraded in the natural environment, can avoid long-term hazard of scale inhibitor emission on the environment, and is nontoxic and harmless to organisms and human beings. The invention further provides a simple and convenient preparation method.

Owner:魏东

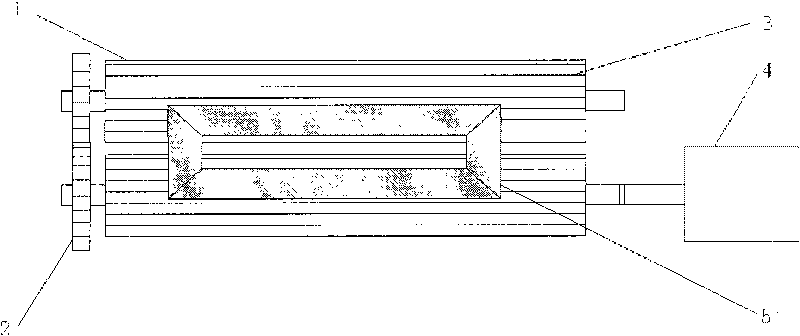

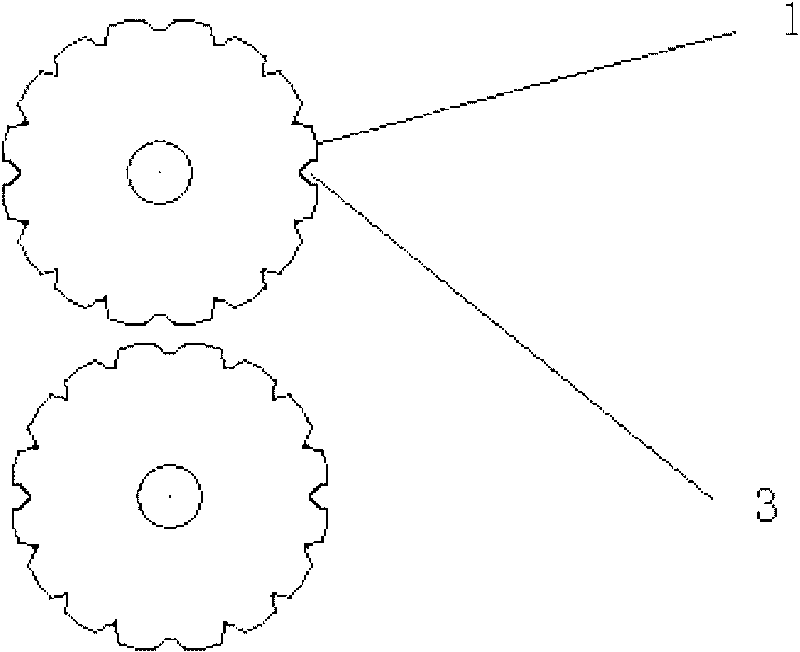

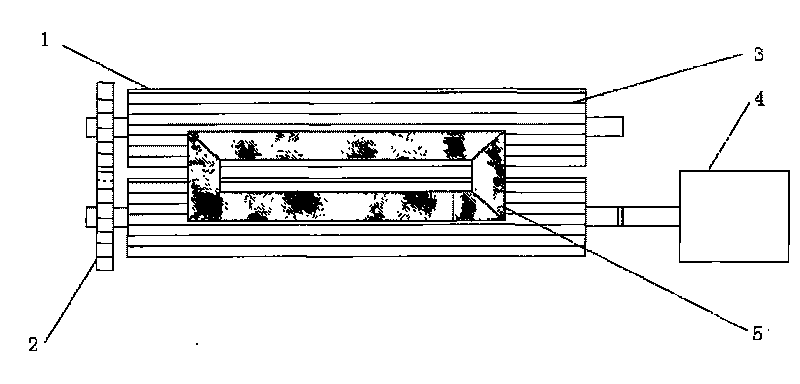

Manufacture method for natural fiber net cover

InactiveCN106003752AIn line with the concept of sustainable developmentEquivalent mechanical strengthGrinding devicesGlass fiberLow temperature curing

The invention relates to a manufacture method for a natural fiber net cover. The manufacture method comprises the following steps: 1, a natural fiber raw materials is subjected to alkali treatment or coupling reagent treatment for modification; 2, the modified natural fiber raw material is continuously stacked to be laminated material through resin liquid coating, or the modified natural fiber raw material is cut into short cut natural fiber; the short cut natural fiber is jointly mixed and dispersively dipped in the resin liquid to form resin paste, and the resin paste is made into a laminated material through roll pressing; 3, the laminated material is cut to obtain a circular natural fiber net cover blank and leftover materials; and 4, the natural fiber net cover blank is subjected to low-temperature curing to form the natural fiber net cover. The natural fiber adopted by the manufacture method is a biological renewable resource, so that a sustainable development idea is met. Compared with a fiber net cover manufactured from glass fiber in the prior art, at the same state, the fiber net cover manufactured from the natural fiber has the advantages that the fiber net cover can naturally degrade, so that no harm is caused to a human body and the environment; the mechanical strength is equivalent; and the production energy consumption is lower.

Owner:高昊

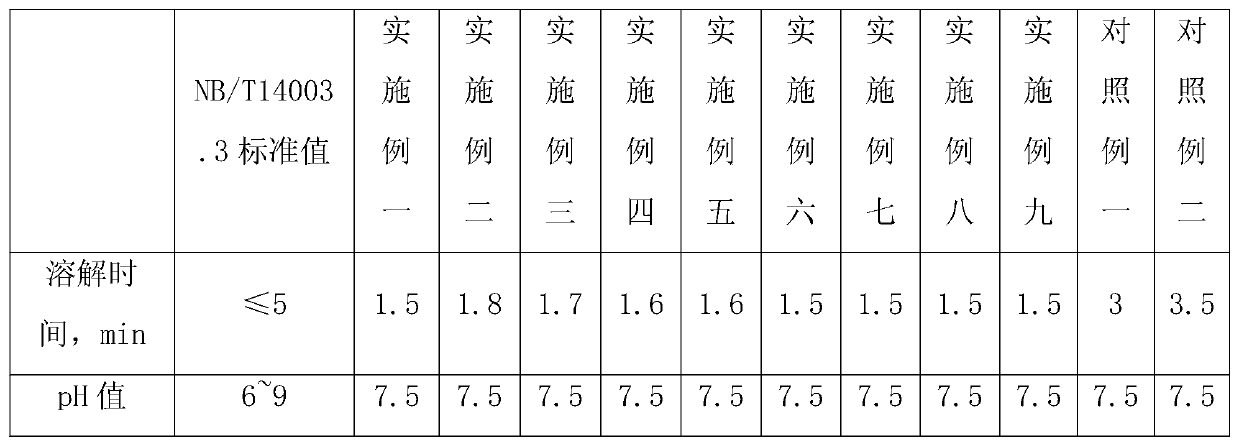

Slickwater fracturing fluid

ActiveCN109868130AIncrease production capacityImprove flowback efficiencyDrilling compositionBiopolymerFracturing fluid

The invention provides a slickwater fracturing fluid. The slickwater fracturing fluid is composed of the following components, in parts by weight: 0.03-0.18 part of a biopolymer resistance reducing agent, 0.12-0.28 part of a clay stabilizing agent, 0.03-0.18 part of a discharge aiding agent, 0.00003-0.00018 part of a gel breaker and 99-100 parts of water. Preferably, the slickwater fracturing fluid is composed of the following components, in parts by weight: 0.05-0.15 part of the biopolymer resistance reducing agent, 0.15-0.25 part of the clay stabilizing agent, 0.05-0.15 part of the dischargeaiding agent, 0.00005-0.00015 part of the gel breaker and 99-100 parts of the water. The slickwater fracturing liquid provided by the invention has a high flowback rate, the flowback substance has high biodegradability, and the flowback fluid has a low mineralization degree, a low fluorine content, low damage to a reservoir, and high environmental friendliness.

Owner:胜利油田世森石油化工有限责任公司

Environment-friendly high-elasticity glue and production process thereof

InactiveCN110093117AEasy to useEasy to degrade naturallyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDebris particleChemistry

The invention discloses environment-friendly high-elasticity glue, and relates to the technical field of the environment-friendly high-elasticity glue. The environment-friendly high-elasticity glue comprises the following raw materials in parts by weight: a main agent comprising 20-120 parts of starch, 30-90 parts of sulfonate, 20-60 parts of gum Arabic, 20-60 parts of lac, 15-40 parts of unsaturated polyester, 25-50 parts of polyurethane, 20-40 parts of organic silicon, 10-50 parts of polyimide, 20-40 parts of bismaleimide, 30-60 parts of allyl resin, 20-100 parts of furan resin and 30-70 parts of amino resin, and an auxiliary agent comprising 1-8 parts of phenolic aldehyde-epoxy resin and 10-20 parts of alpha cyanoacrylate. The environment-friendly high-elasticity glue takes the naturalraw materials such as the starch, the sulfonate, the gum Arabic and the like as the main agent, so that when the high-elasticity glue with the ingredients is produced, the high-elasticity glue is moreconvenient to use and easier to naturally degrade, and the problem that the existing high-elasticity glue generates more pollutants which are difficult to degrade in the environment during productionand use, the pollutants can affect water resources and land resources, and debris particles can enter organisms along with the circulation of natural water quality and affect metabolism of organismsis solved.

Owner:湖北君邦新材料科技有限公司

Botanical insecticide its preparation method

InactiveCN1247096CEasy to useEasy to degrade naturallyBiocideArthropodicidesMedicinal herbsNicotiana tabacum

A vegetative insecticide is prepared from 8 Chinese-medicinal herbs including leftover of tobacco, Sichuan chinaberry, wild chrysanthemum flower, etc through carefully choosing raw materials, drying in air, pulverizing, immersing filter, steaming and concentrating. Its advantages are high effect, no environmental pollution, and improving soil.

Owner:李廷伦

Biological rodenticide with deratization effect and preparation method of biological rodenticide

PendingCN112690292AHas the effect of killing rodentsAnticoagulantBiocideChemosterilantsBiotechnologySecondary poisoning

The invention provides a biological rodenticide with a deratization effect, which comprises the following raw materials in parts by weight: 15-45 parts of compound fermentation activity extraction micro-powder and 55-85 parts of mouse luring feed, wherein the compound fermentation activity extraction micro-powder is obtained by natural fermentation of a mixture of tripterygium wilfordii coarse powder and blue algae mud. The biological rodenticide has multiple deratization effects of poisoning, anticoagulation, antifertility and neurotoxicity, has an excellent deratization effect, does not pollute the environment, does not easily cause drug resistance, does not generate a secondary poisoning phenomenon and is easy to naturally degrade.

Owner:丁柯中

Easily degradable pesticide

InactiveCN108605995ASynergistic effect is obviousStrong medicineBiocideAnimal repellantsHerbEnvironmentally friendly

The invention relates to the technical field of pesticides and discloses an easily degradable pesticide. The pesticide is prepared from, in parts by weight, 10-14 parts of vernonia anthelmintica, 15-21 parts of camphor tree leaves, 22-26 parts of folium artemisiae argyi, 13-18 parts of juniper, 16-20 parts of rhododendron spinuliferum, 15-18 parts of common threewingnut roots, 17-21 parts of sweetwormwood herb, 8-12 parts of sanguinarine and 8-12 parts of 35%-45% streptomyces jingyangensis. The easily degradable pesticide has strong and lasting efficacy and is a vegetative organic pesticide,positioning components of the pesticide are extracted from plants, pesticide residues can be naturally degraded after the pesticide is sprayed on crops to kill diseases and pests by poison, and the pesticide is environmentally friendly.

Owner:吴道华

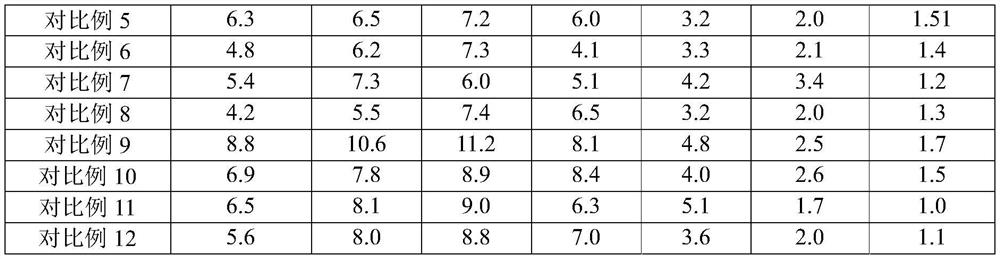

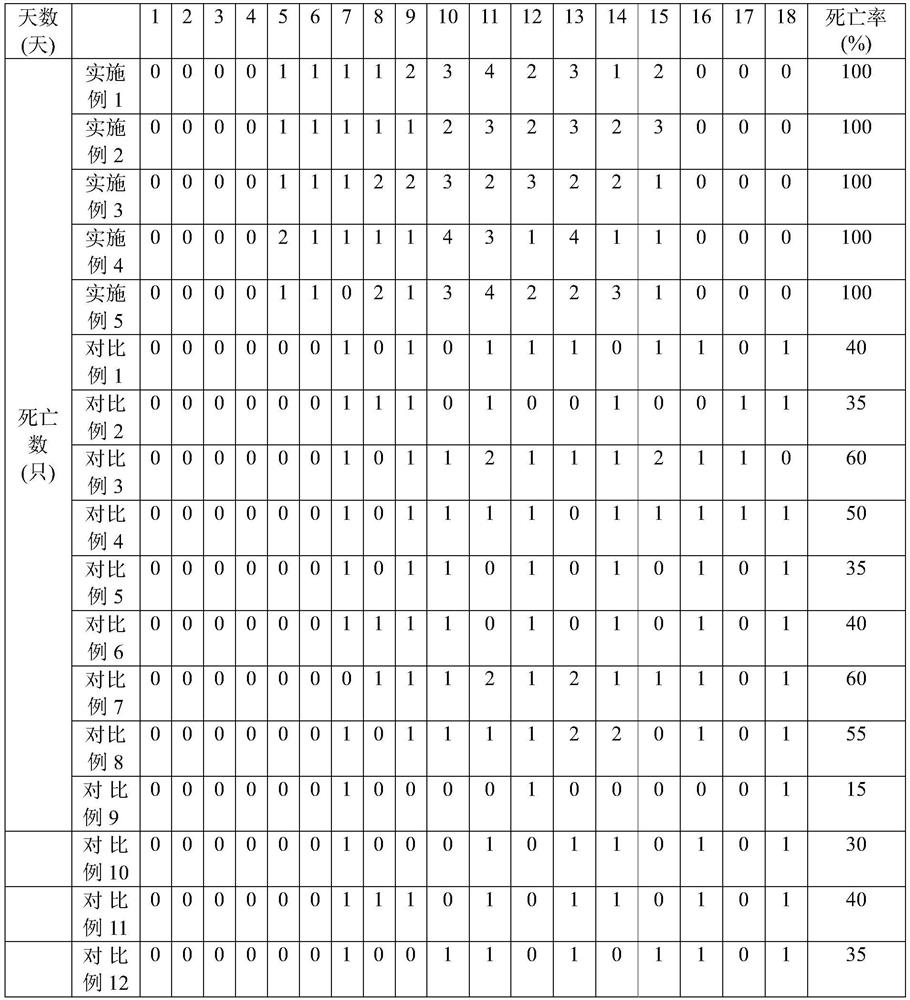

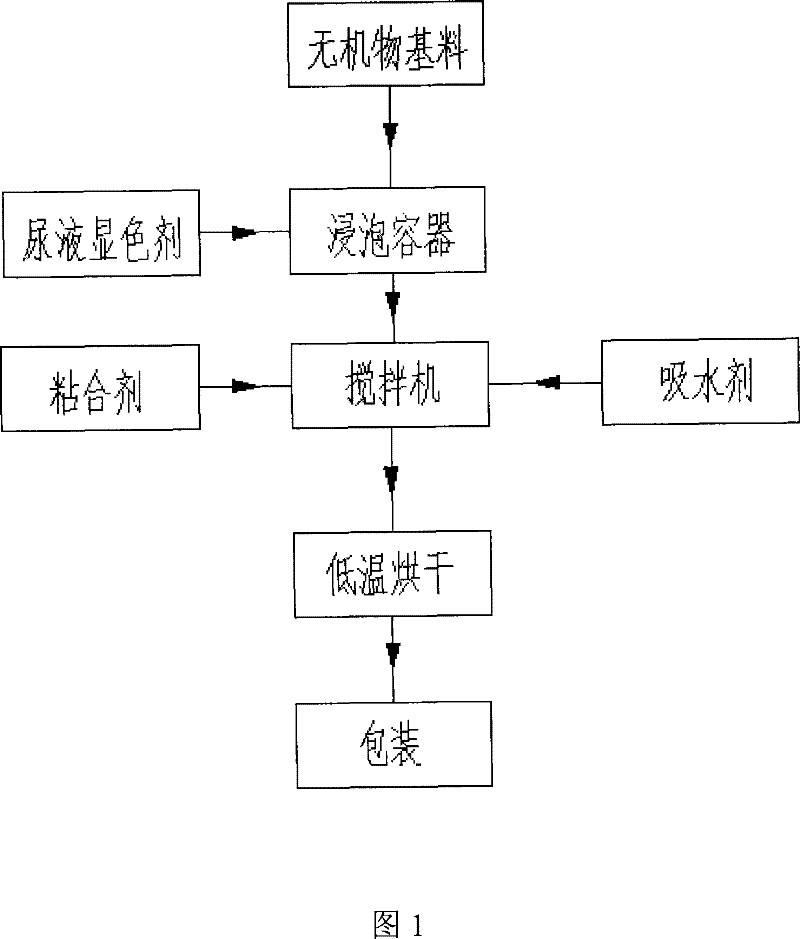

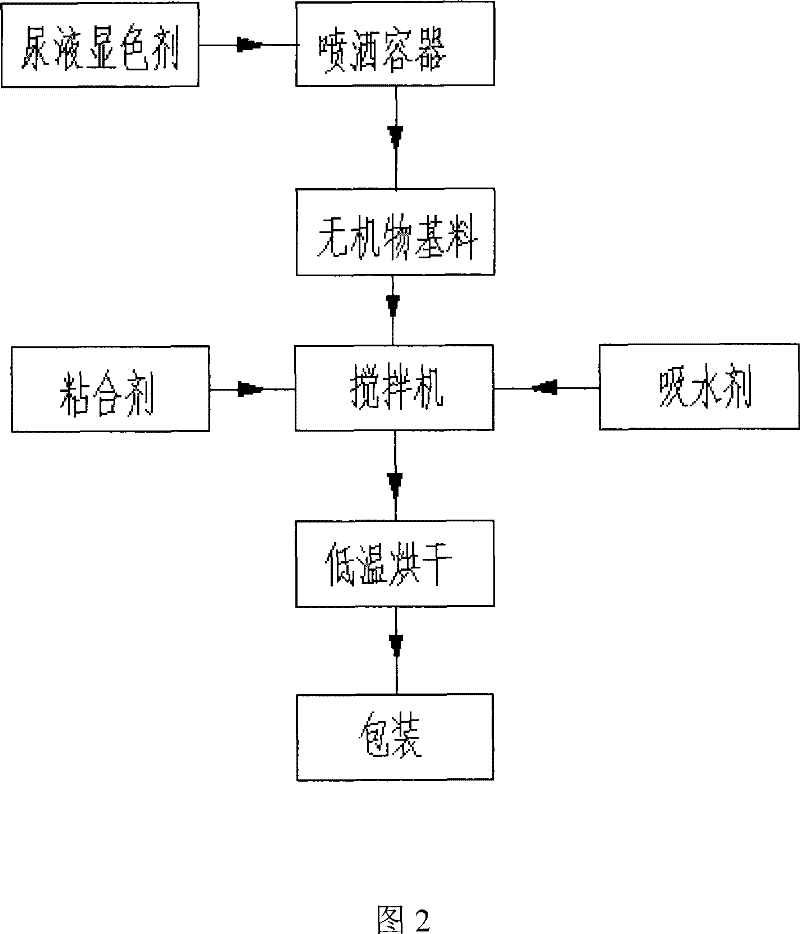

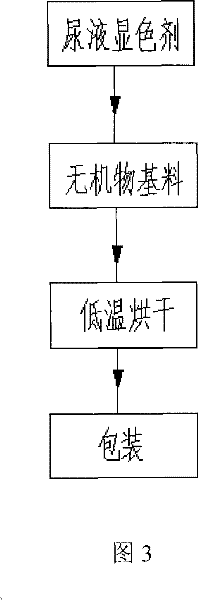

Preparation method of animals urine checking granule

InactiveCN101140278BAvoid cross infectionHealthy and happy lifeMaterial analysis by observing effect on chemical indicatorAnimal housingDiseaseAnimal science

Owner:刘世安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com