Preparation method of modified polyurethane sealant

A polyurethane sealant and modification technology, which is applied in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc., can solve problems such as low tensile strength and high viscosity of sealants, and achieve improved alkali resistance , excellent sealing performance, simple and easy-to-control preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

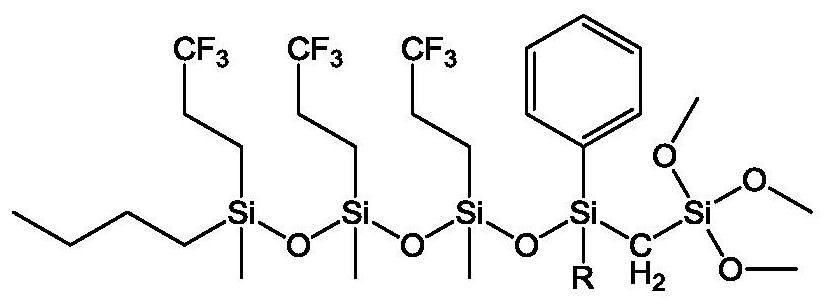

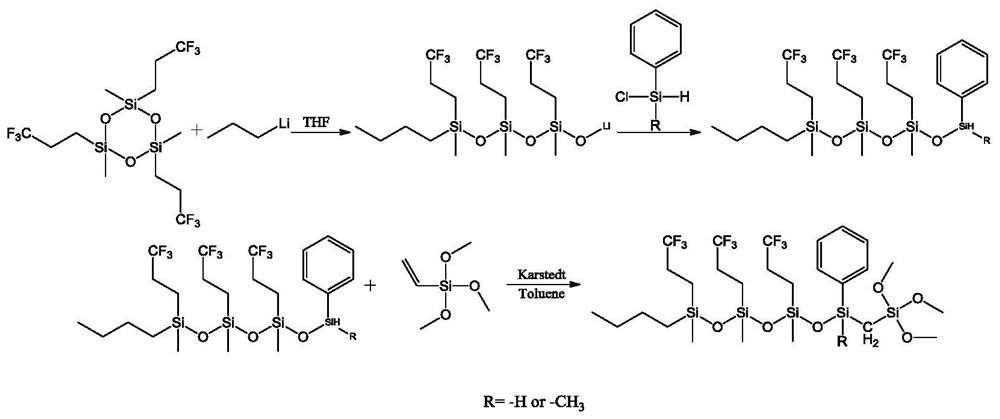

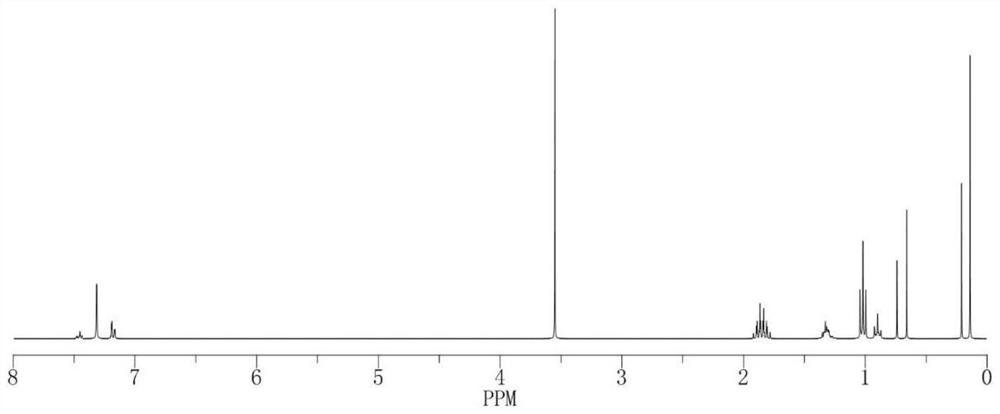

[0075] Embodiment 1: A kind of fluorine-containing silane coupling agent:

[0076] Under nitrogen, add 60mL tetrahydrofuran to 0.1mol trifluoropropylmethylcyclotrisiloxane (46.8g), inject a n-hexane solution containing 0.1mol n-butyllithium (5.0g) with a syringe after ice-water bath, and react for 2h Then inject 0.1mol methylphenylchlorosilane (15.6g) into a syringe to end-cap for 12h; wash the product with n-hexane after the reaction, separate the organic phase, wash with deionized water for 3 times, and dry with anhydrous sodium sulfate for 5h. The solvent and unreacted monomers were removed by pressure distillation to obtain 60.91 g of hydrosilane, with a yield of about 94.29%; under nitrogen, 0.31 mol of vinyltrimethoxysilane (45.9 g) was added to 100 g of toluene, and then 0.0071 mmol of Karstedt catalyst was added , 4°C / min to raise the temperature to 82°C, add hydrosilane dropwise into the mixed solution very slowly, the dropwise addition is completed in 6 hours, and re...

Embodiment 2

[0078] Embodiment 2: Another fluorine-containing silane coupling agent:

[0079] This example provides another fluorine-containing silane coupling agent according to the method described in Example 1. The only difference from Example 1 is that the hydrosilane is added dropwise within 1 hour to obtain the final product fluorine-containing silane coupling agent. The joint agent is 50.72g, and the yield is about 65.03%.

Embodiment 3

[0080] Embodiment 3: Another fluorine-containing silane coupling agent:

[0081] This example provides another fluorine-containing silane coupling agent according to the method described in Example 1. The difference from Example 1 is that the hydrosilane is added dropwise within 3 hours to obtain the final product fluorine-containing silane coupling agent. The joint agent is 61.22g, and the yield is about 78.49%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com