Method for preparing citrus peel-residue paper pulp mould

A technology of citrus peel residue and pulp mold, applied in textile and papermaking, raw material separation and other directions, can solve the problems of poor product quality, difficult molding, low strength, etc., achieve complete molding, increase surface area and cross-linking strength, and improve tensile strength. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: (Preparation method of citrus peel residue pulp mold 1)

[0026] The method in this example is carried out as follows:

[0027] (1) Pretreatment of citrus peel and dregs: collect the peel and dregs of Wenzhou Citrus fruit in the process of processing canned syrup orange slices as raw materials, after removing impurities, rinsing and draining, for use;

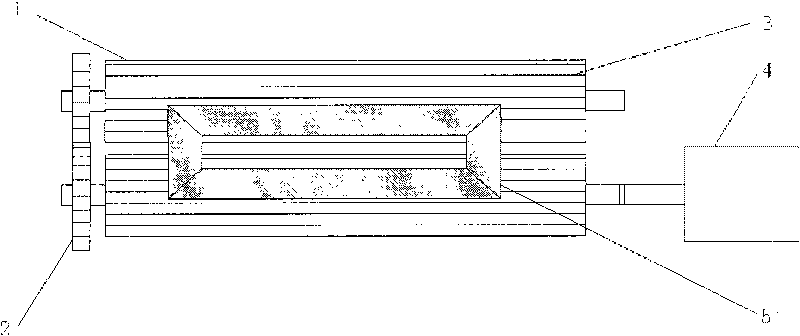

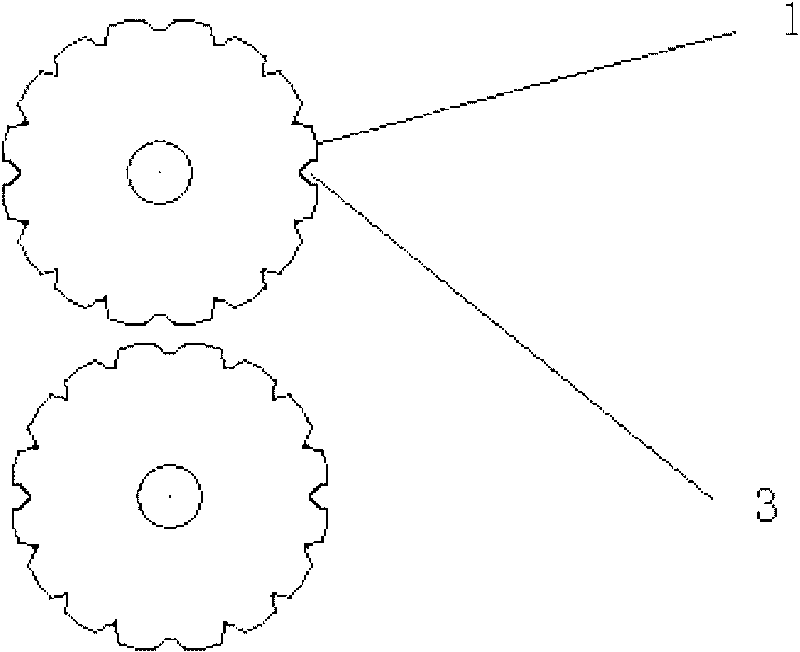

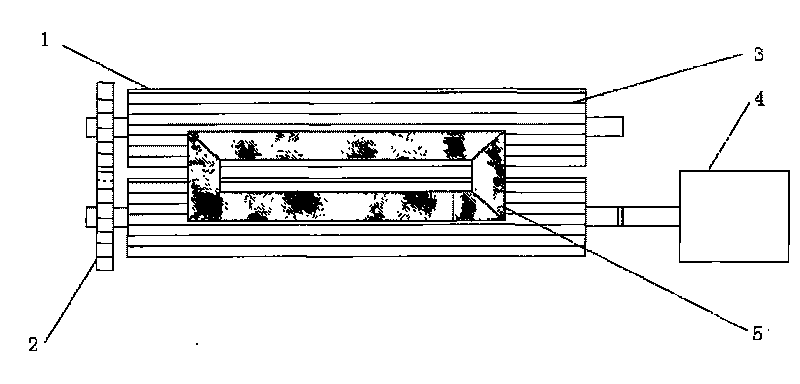

[0028] (2) The rolling treatment of citrus peel residue: the distance between the two rollers 1 in the citrus peel residue rolling device with a groove 3 of 1 mm in width is sequentially adjusted to 2 mm and 0.1 mm; the raw material after step (1) pretreatment Divide into 3 parts; when the distance between the two rollers 1 is 2mm, add 2 of them to the hopper 5, and start the motor 4 to drive the roller 1 to rotate, and the raw materials are rolled into a mesh-like rolled product; When the distance is 0.1mm, use the same method as above to crush 1 part of the raw material into the finest granular compacted product, ...

Embodiment 2

[0031] Example 2: (Preparation method of citrus peel residue pulp mold 2)

[0032] In this example, step (1) collect the peels and residues of local early fruits that were discarded during the processing of canned syrup orange slices as raw materials; step (2) use the two rollers in the citrus peel and residue rolling device with groove 3 of 5mm Adjust the distance between 1 to 2mm, 1.5mm and 0.5mm in sequence; divide the pretreated raw material in step (1) into 4 parts; when the distance between the two rollers 1 is 2mm, add 2 parts of it to the hopper 5; When the distance between the rollers 1 is 1.5mm and 0.5mm respectively, add 1 part of each into the hopper 5; store the three grades 1, 2 and 4 respectively; step (3) put the three grades of citrus peel The crushed residues were degummed with 0.5% pectinase aqueous solution in a ratio of 1:10 by weight at a liquid temperature of 40°C for 10 minutes, and then stored separately; step (4) degummed the three-stage citrus peel The...

Embodiment 3

[0033] Example 3: (Preparation method of citrus peel residue pulp mold 3)

[0034] In this example, step (1) collect the peels and residues discarded during the juice processing of sweet orange fruits as raw materials; step (2) the distance between the two rollers in the citrus peel and residue rolling device with a groove 3 of 3mm in width Adjust to 2mm, 1.5mm, 1mm and 0.1mm in sequence; divide the pretreated raw material in step (1) into 5 parts; when the distance between the two rollers 1 is 2mm, add 2 of them to the hopper 5; when the two rollers When the distance between one room is 1.5mm, 1mm, and 0.1mm, respectively, add 1 portion to the hopper 5; store the four grades 1, 2, 3, and 5 respectively; 5 The four grades of compacted materials are stored separately; step (3) The four grades of citrus peel compacted materials are respectively treated with 0.3% hydrochloric acid aqueous solution at a weight ratio of 1:7 at a liquid temperature of 20°C for 100 minutes After degumm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com