Sustained-release scale inhibitor and preparation method thereof

A scale inhibitor and slow-release technology, applied in the field of slow-release scale inhibitor and its preparation, can solve the problems of difficult degradation, restricted use, adverse health, etc., and achieve the effects of good biodegradability, rapid degradation, and long-term harm avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

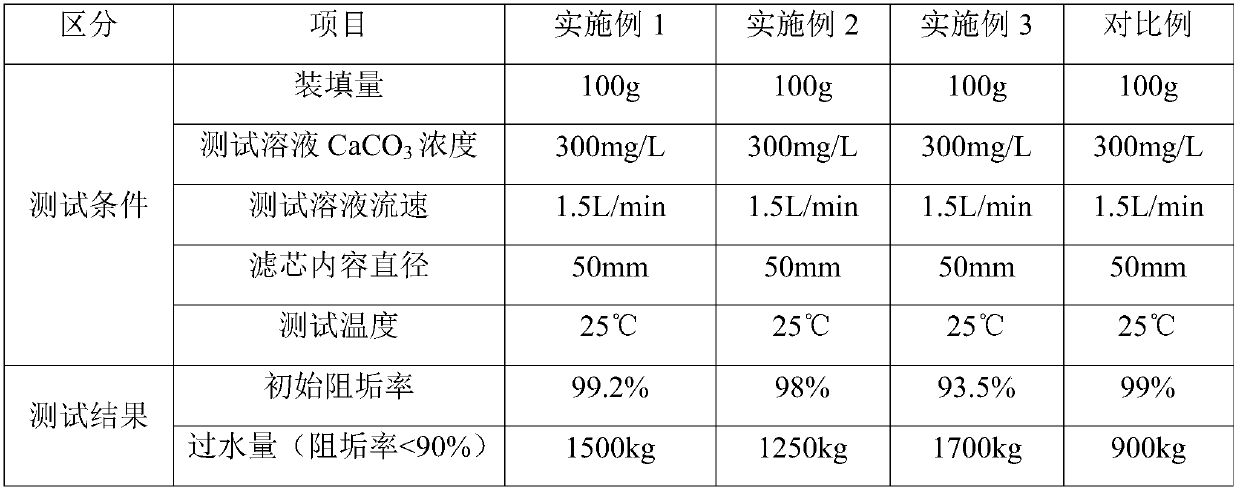

Examples

Embodiment 1

[0029] (1) first weigh polyhistidine and sodium citrate according to the mass ratio of 1:1, and put into a ball mill, and ball mill for 20 minutes to make it mix evenly;

[0030] (2) Weigh diatomaceous earth of the same quality as the mixture obtained in step (1), drop into the mixture obtained in step (1), and continue ball milling for 40 minutes to make it evenly mixed;

[0031] (3) Put the mixture in the step (2) into a granulator to make φ3~4mm compact granules, and dry them to make them have a certain strength;

[0032] (4) Weigh kaolin with the same quality as the dried granules obtained in step (3), and ball mill for 45 minutes; use the granules obtained in step (3) as seed granules, and put them into a granulator for granulation to make φ5~6mm granules ;

[0033] (5) drying the granules prepared in step (4) at a temperature of 180° C., and the outer layer of kaolin forms a shell with strength;

[0034] (6) Weigh kaolin that is twice the quality of the particles obtai...

Embodiment 2

[0036] (1) First take polyhistidine and sodium gluconate according to the mass ratio of 1.5:1, and put into a ball mill, and ball mill for 30 minutes to make it mix uniformly;

[0037] (2) Weigh diatomaceous earth of the same quality as the mixture obtained in step (1), put it into the mixture obtained in step (1), and continue ball milling for 60 minutes to make it evenly mixed;

[0038] (3) Put the mixture in the step (2) into a granulator to make φ3~4mm compact granules, and dry them to make them have a certain strength;

[0039] (4) Weigh kaolin with the same quality as the dried particles obtained in step (3), and ball mill for 30 minutes; use the particles obtained in step (3) as seed particles, put them into a granulator for granulation, and make φ5~6mm particles ;

[0040] (5) drying the granules prepared in step (4) at a temperature of 150° C., and the outer layer of kaolin forms a shell with strength;

[0041] (6) Weigh kaolin that is twice the quality of the parti...

Embodiment 3

[0043] (1) first weigh polyhistidine and sodium salicylate according to the mass ratio of 1.2:1, and put into a ball mill, and ball mill for 15 minutes to make it mix uniformly;

[0044] (2) Take by weighing the zeolite powder of the same quality as the mixture obtained in step (1), put it into the mixture obtained in step (1), and continue ball milling for 30 minutes to make it evenly mixed;

[0045] (3) Put the mixture in the step (2) into a granulator to make φ3~4mm compact granules, and dry them to make them have a certain strength;

[0046] (4) Weigh kaolin with the same quality as the dried granules obtained in step (3), and ball mill for 45 minutes; use the granules obtained in step (3) as seed granules, and put them into a granulator for granulation to make φ5~6mm granules ;

[0047] (5) drying the granules prepared in step (4) at a temperature of 120° C., and the outer layer of kaolin forms a shell with strength;

[0048](6) Weigh the kaolin that is twice the qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com