Environmental-friendly powder-baking compact powder and preparation method thereof

A technology for baking powder and powder cake, which is applied to body powder, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as non-degradation, pollution, skin damage, etc., and achieve the effects of strong UV resistance, high efficiency, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

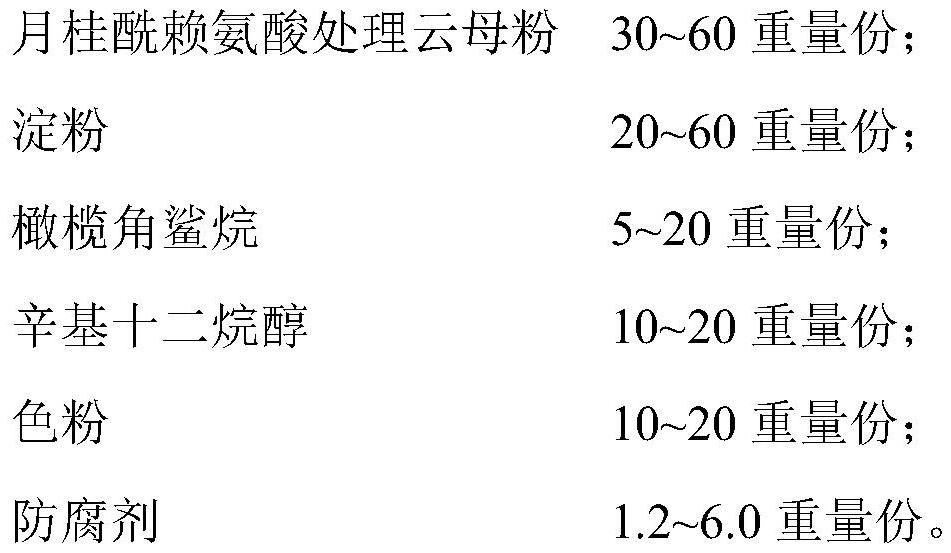

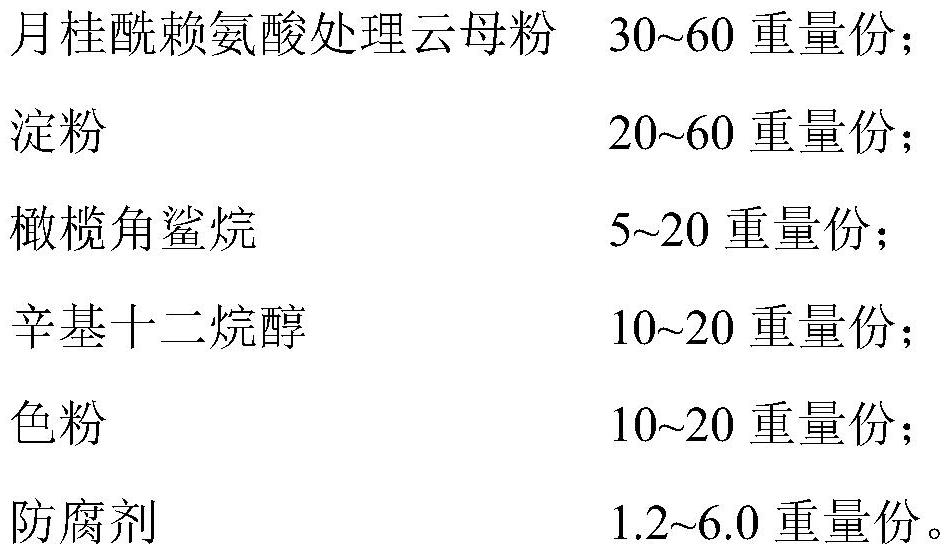

Method used

Image

Examples

Embodiment 1

[0042] Adopt following preparation method according to the present invention to prepare environment-friendly baked powder powder cake:

[0043] (1) Treat mica powder with 45g of lauroyl lysine, 20g of cornstarch, 20g of rice starch, 10g of color powder, 0.3g of potassium sorbate, 0.3g of honokiol and 3g of pentylene glycol Mix, stir evenly under the condition of stirring speed 4000r / min, stirring time 3.0min;

[0044] (2) Mix 12g of olive squalane and 15g of octyldodecanol evenly, join in the result of step (1), add 4.0g of water at the same time, then at a stirring speed of 3800r / min, the stirring time Stir again under the condition of 1.7min;

[0045] (3) the gain of step (2) is put into the mould;

[0046] (4) Dry the product obtained in step (2) at a drying temperature of 55° C. and a drying time of 10 hours.

[0047] Thus, the environmentally friendly baked powder cake (particle size 10 μm) according to the present invention is obtained.

Embodiment 2

[0049] Adopt following preparation method according to the present invention to prepare environment-friendly baked powder powder cake:

[0050](1) Treat mica powder with 45g of lauroyl lysine, 30g of cornstarch, 10g of rice starch, 13g of color powder, 0.1g of potassium sorbate, 0.5g of honokiol and 2g of pentylene glycol Mix, stir evenly under the conditions of stirring speed 3700r / min and stirring time 4.0min;

[0051] (2) Mix 10g of olive squalane and 10g of octyldodecanol evenly, add to the result of step (1), and add 5.0g of water at the same time, then at a stirring speed of 4000r / min, the stirring time Stir again under the condition of 1.5min;

[0052] (3) the gain of step (2) is put into the mould;

[0053] (4) Dry the product obtained in step (2) at a drying temperature of 55° C. and a drying time of 11 hours.

[0054] Thus, the environmentally friendly baked powder cake (particle size 10 μm) according to the present invention is obtained.

Embodiment 3

[0056] Adopt following preparation method according to the present invention to prepare environment-friendly baked powder powder cake:

[0057] (1) Treat mica powder with 60g of lauroyl lysine, 10g of cornstarch, 15g of rice starch, 10g of color powder, 0.5g of potassium sorbate, 0.1g of honokiol and 5g of pentylene glycol Mix, stir evenly under the conditions of stirring speed 4200r / min and stirring time 3.0min;

[0058] (2) Mix 15g of olive squalane and 10g of octyldodecanol evenly, add to the result of step (1), and add 3.5g of water at the same time, then at a stirring speed of 4000r / min, stirring time Stir evenly again under the condition of 1.2min;

[0059] (3) the gain of step (2) is put into the mould;

[0060] (4) drying the product obtained in step (2) at a drying temperature of 50° C. and a drying time of 9 hours.

[0061] Thus, the environmentally friendly baked powder cake (particle size 15 μm) according to the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com