Film bulk acoustic resonator (FBAR) and preparation method thereof

A thin-film bulk acoustic wave and resonator technology, applied in the field of microelectronics, can solve the problems of large silicon integrated circuits, insufficient reliability, and low yield, and achieve improved circuit performance, convenient sensing, and strong mechanical fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

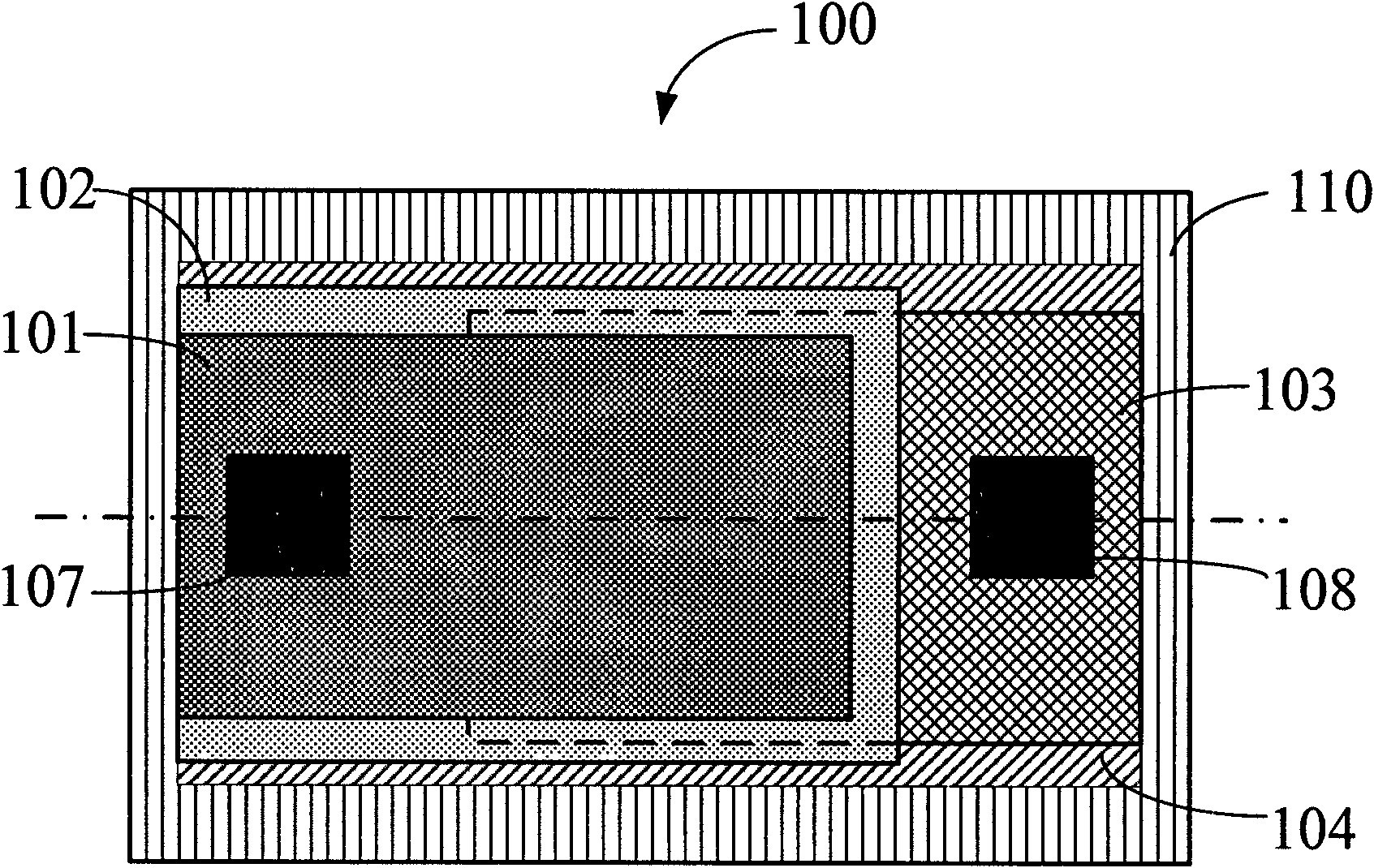

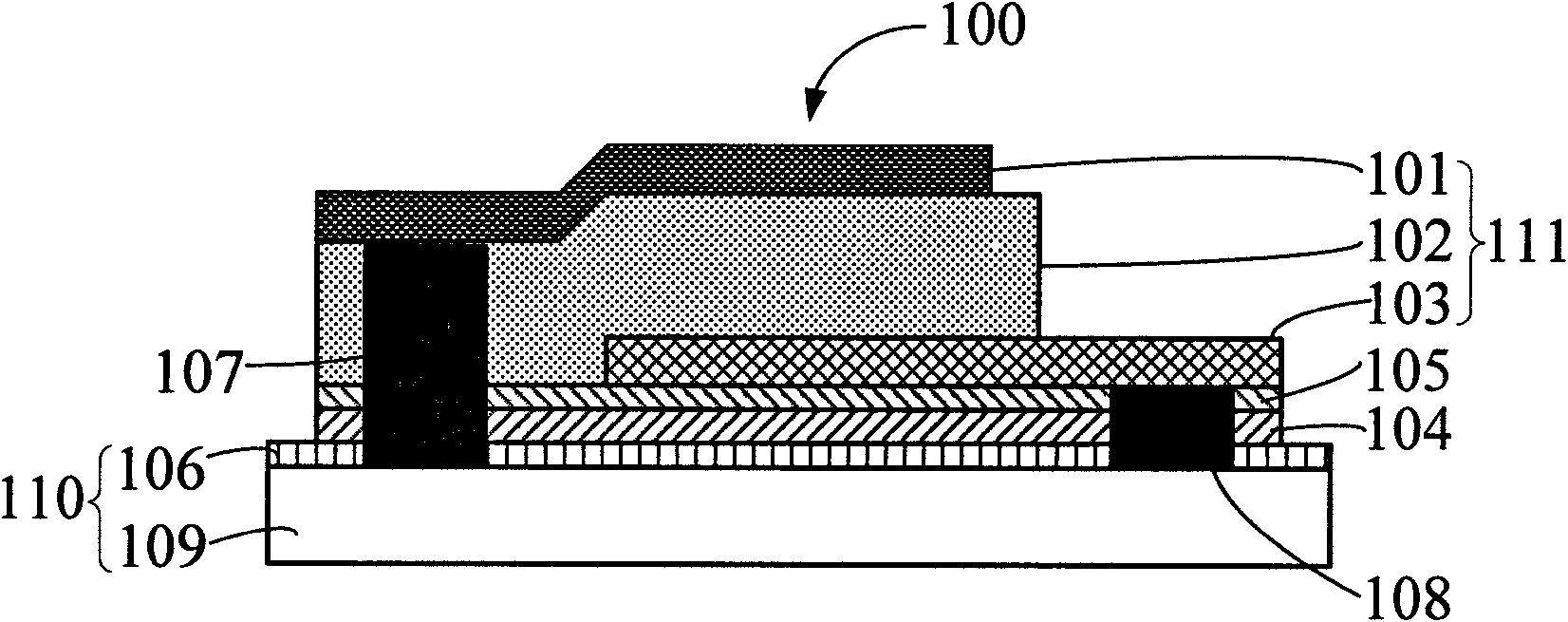

[0022] see figure 1 , a schematic top view of the integrated structure of the FBAR with a Bragg reflective layer of the present invention, figure 2 is a schematic cross-sectional view of an integrated structure of an FBAR using a Bragg reflection layer according to an embodiment of the present invention.

[0023] The FBAR in the figure includes a substrate 110 , an acoustic wave reflection layer on it and a sandwich piezoelectric stack 111 , and the acoustic wave reflection layer in the figure is composed of a layer of low acoustic impedance film 104 and a layer of high acoustic impedance film 105 .

[0024] The substrate 110 is composed of an integrated circuit chip 109 capable of FBAR signal processing and a passivation layer 106 deposited on the integrated circuit chip 109 and whose surface is polished.

[0025] The sandwich piezoelectric stack includes an upper electrode 101 , a lower electrode 103 and a piezoelectric layer 102 .

[0026] The sandwich piezoelectric stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com