Slickwater fracturing fluid

A water fracturing and slippery technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as neurological, reproductive and developmental toxicity, increased salinity of flowback fluid, land salinization, etc., to achieve Improve anti-expansion and anti-migration capabilities, reduce pumping friction, and increase injection displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

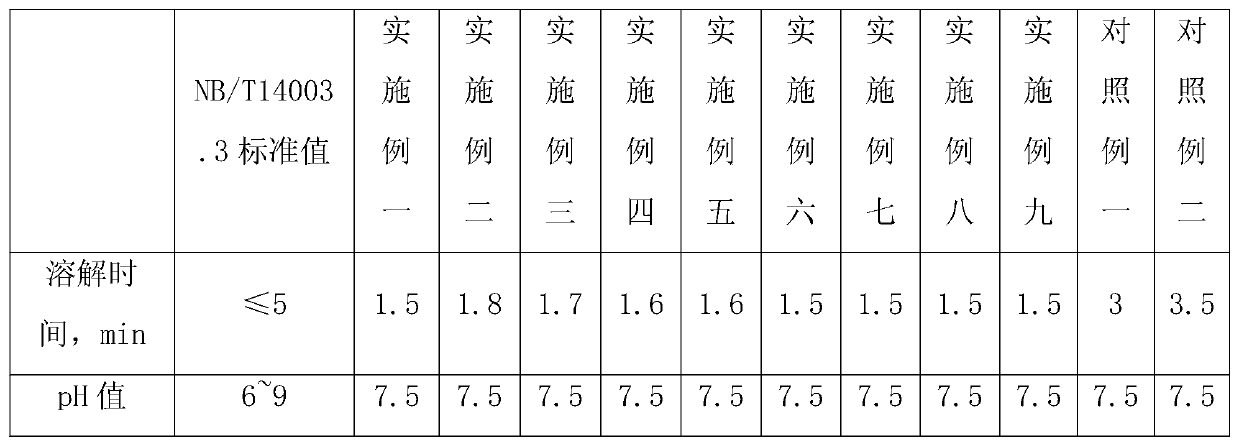

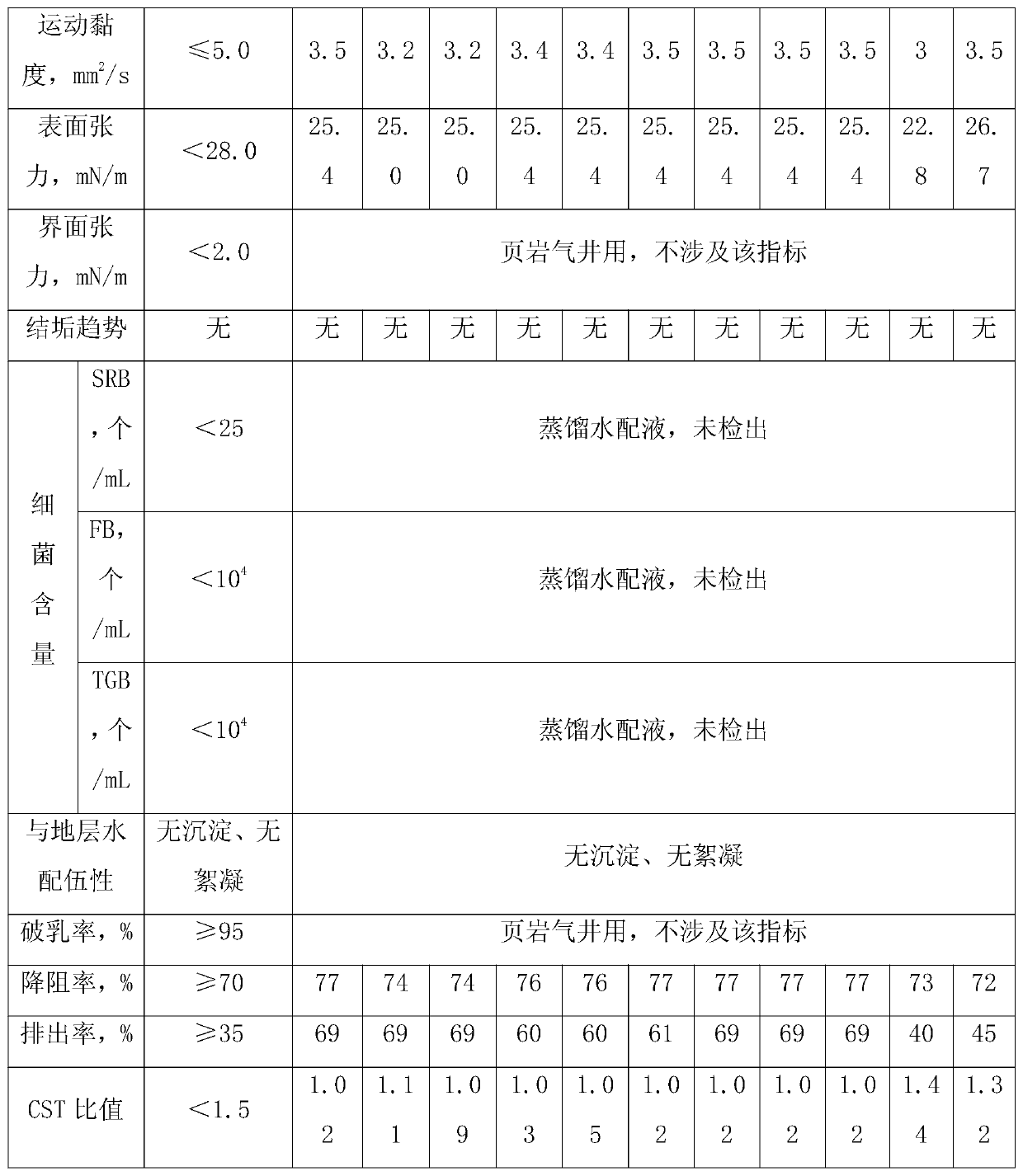

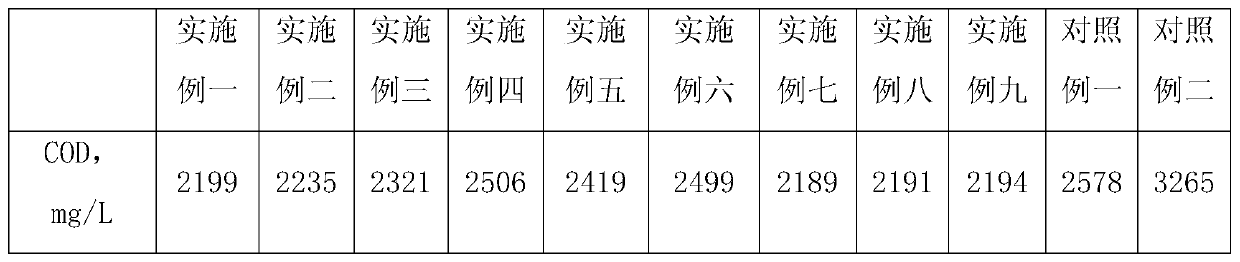

Examples

Embodiment 1

[0043] The slick water fracturing fluid described in this embodiment consists of the following components in parts by weight:

[0044] 0.10 part of instant high-viscosity guar gum, 0.20 part of clay stabilizer, 0.10 part of drainage aid, 0.0001 part of high-temperature biological enzyme breaker and 99.6999 parts of water.

[0045]Wherein the viscosity of instant high-viscosity guar gum is: 0.48% high-viscosity guar gum is in 2% potassium chloride solution, 3min viscosity is greater than 45cP@Fann35100rpm, 25 ℃, 2h viscosity is greater than 50cP@Fann35 100rpm, 25 ℃;

[0046] Clay stabilizer is the polydimethyldiallyl ammonium chloride (molecular weight 50000) of 15 parts by weight, the solution of the choline chloride of 40 parts and the water of 45 parts;

[0047] Drainage aid is the limonene that parts by weight are 30 parts, the ethylene glycol monobutyl ether of 5 parts, the alkyl glucoside (APG12 / 14) of 7.5 parts, the microemulsion that the water of 2.5 parts of ethanol an...

Embodiment 2

[0053] The slick water fracturing fluid described in this embodiment consists of the following components in parts by weight:

[0054] 0.15 parts of instant high-viscosity guar gum, 0.15 parts of clay stabilizer, 0.05 parts of drainage aid, 0.00005 parts of high-temperature biological enzyme breaker and 99.64995 parts of water.

[0055] Wherein the viscosity of instant high-viscosity guar gum is: 0.48% high-viscosity guar gum is in 2% potassium chloride solution, 3min viscosity is greater than 45cP@Fann35100rpm, 25 ℃, 2h viscosity is greater than 50cP@Fann35 100rpm, 25 ℃;

[0056] The clay stabilizer is the polydimethyldiallyl ammonium chloride (molecular weight 50000) of 20 parts by weight, the solution of the choline chloride of 45 parts and the water of 35 parts;

[0057] Drainage aid is the limonene that parts by weight are 25 parts, the ethylene glycol monobutyl ether of 1 part, the alkyl glucoside (APG12 / 14) of 4.5 parts, the microemulsion that the water of 1.5 parts of ...

Embodiment 3

[0062] The slick water fracturing fluid described in this embodiment consists of the following components in parts by weight:

[0063] 0.05 part of instant high-viscosity guar gum, 0.25 part of clay stabilizer, 0.15 part of drainage aid, 0.00015 part of high-temperature biological enzyme breaker and 99.54985 parts of water.

[0064] Wherein the viscosity of instant high-viscosity guar gum is: 0.48% high-viscosity guar gum is in 2% potassium chloride solution, 3min viscosity is greater than 45cP@Fann35100rpm, 25 ℃, 2h viscosity is greater than 50cP@Fann35 100rpm, 25 ℃;

[0065] Clay stabilizer parts by weight are the polydimethyldiallyl ammonium chloride (molecular weight 50000) of 10 parts, the solution of the choline chloride of 35 parts and the water of 55 parts;

[0066] Drainage aid is the limonene of 35 parts by weight, the ethylene glycol monobutyl ether of 9 parts, the alkyl glucoside (APG12 / 14) of 11.5 parts, the microemulsion that the water of 3.5 parts of ethanol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com