A vapor-permeable flame-retardant anti-soaking fabric and its preparation method

A fabric and vapor-permeable technology, applied in chemical instruments and methods, fireproof coatings, polyurea/polyurethane coatings, etc., can solve problems such as large hydrostatic pressure drop, difficult processing, and meeting expected requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

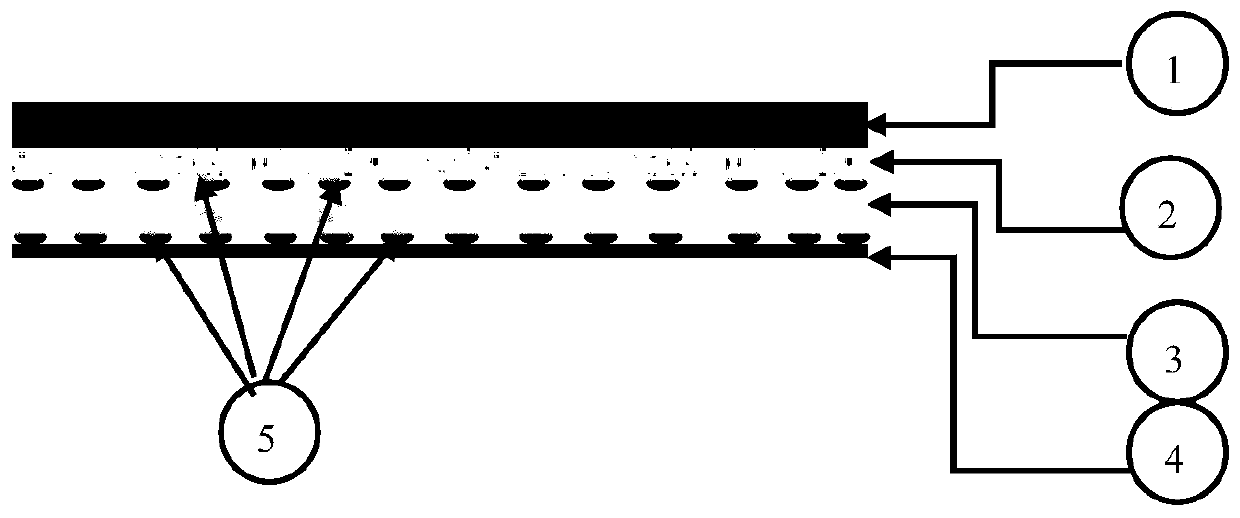

Image

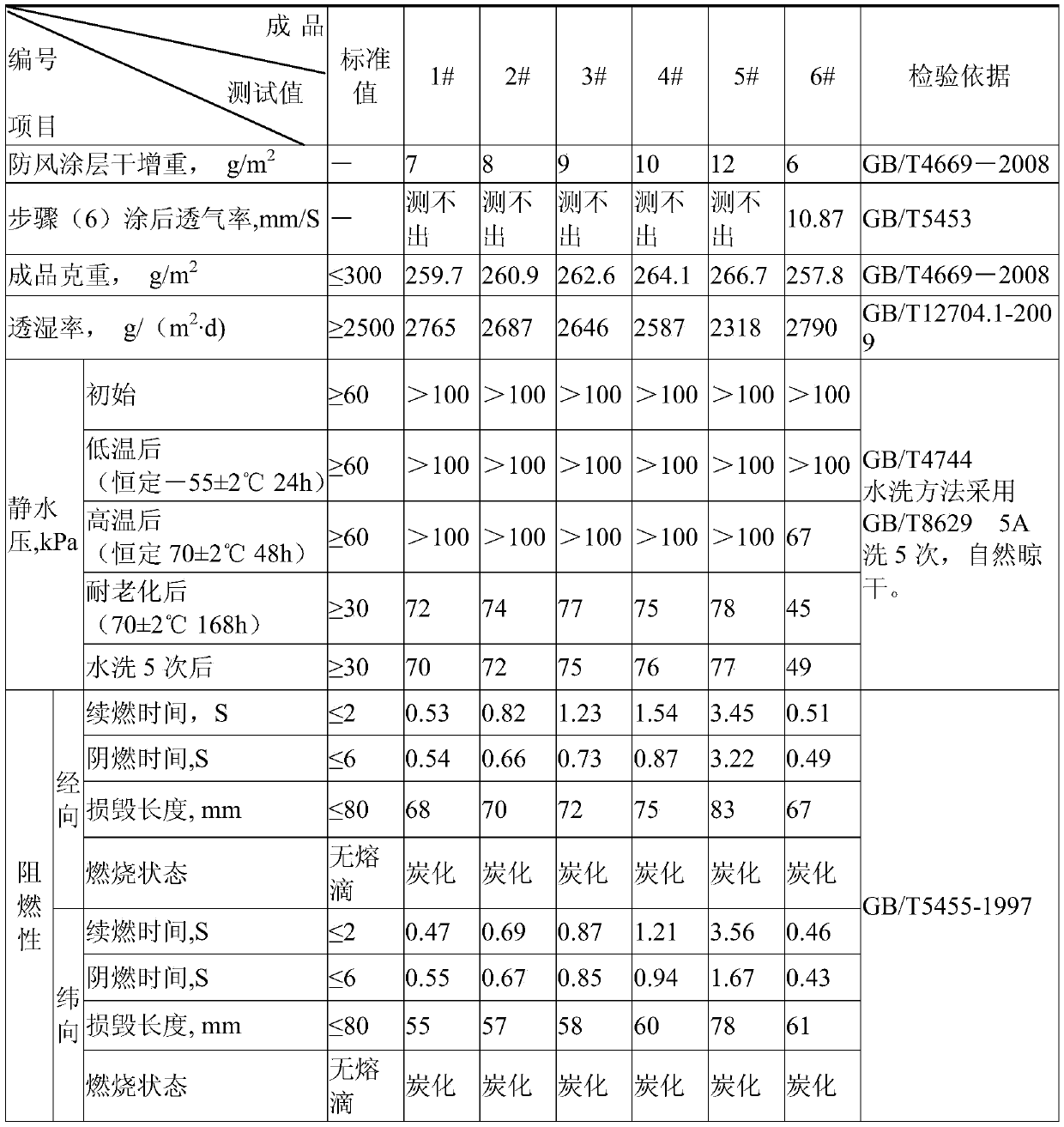

Examples

Embodiment 1

[0108] (1) Fabric selection: the outer fabric is aramid plain weave fabric 40 S / 2*40 S / 2 / 248*216, the inner fabric is aramid knitted mesh (yarn count 40S, weight 30g / m 2 ).

[0109] (2) The material of the intermediate film is polytetrafluoroethylene / polyurethane composite film (thickness 30μm, weight 35g / m 2 ).

[0110] (3) Water-repellent finishing of the outer fabric: use fluorine-based waterproofing agent (TX-15) for padding finishing, temperature is 160°C, time is 1min, drying, water-staining grade ≥ 4;

[0111] (4) Calender the outer fabric after the water-repellent finishing with a calender at a pressure of 10 MPa, a temperature of 110° C., and a speed of 20 m / min.

[0112] (5) Coating glue preparation, raw material weight ratio:

[0113] Reactive polyurethane resin D-ACE 2345: 100 parts

[0114] Butanone: 10 parts

[0115] Toluene: 15 parts

[0116] Isocyanate crosslinking agent D-ACE 555: 2.0 parts

[0117] Cross-linking accelerator D-ACE 900: 1.2 parts

...

Embodiment 2

[0125] (1) Fabric selection: the outer fabric is aramid plain weave fabric 40 S / 2*40 S / 2 / 248*216, the inner fabric is aramid knitted mesh (yarn count 40S, weight 30g / m 2 ).

[0126] (2) The material of the intermediate film is polytetrafluoroethylene / polyurethane composite film (thickness 30μm, weight 35g / m 2 ).

[0127] (3) Water-repellent finishing is carried out on the outer fabric, and the water-staining grade is ≥4.

[0128] (4) Calender the outer fabric after the water-repellent finishing with a calender, the pressure is 11Mpa, the temperature is 110°C, and the vehicle speed is 25m / min.

[0129] (5) Coating glue preparation, raw material weight ratio:

[0130] Reactive polyurethane resin D-ACE 2345: 100 parts

[0131] Butanone: 5 parts

[0132] Toluene: 20 parts

[0133] Isocyanate crosslinking agent D-ACE 555: 2.5 parts

[0134] Cross-linking accelerator D-ACE 900: 1.5 parts

[0135] Melamine crosslinking agent D-ACE557: 0.3 parts

[0136] Add butanone and ...

Embodiment 3

[0142] (1) Fabric selection: the outer fabric is aramid plain weave fabric 40 S / 2*40 S / 2 / 248*216, the inner fabric is aramid knitted mesh (yarn count 40S, weight 30g / m 2 ).

[0143] (2) The material of the intermediate film is polytetrafluoroethylene / polyurethane composite film (thickness 30μm, weight 35g / m 2 ).

[0144] (3) Water-repellent finishing is carried out on the outer fabric, and the water-staining grade is ≥4.

[0145] (4) Calender the outer fabric after water-repellent finishing with a calender, the pressure is 11Mpa, the temperature is 120°C, and the vehicle speed is 30m / min;

[0146] (5) Coating glue preparation, raw material weight ratio:

[0147] Reactive polyurethane resin D-ACE 2345: 100 parts

[0148] Butanone: 8 parts

[0149] Toluene: 17 parts

[0150] Isocyanate crosslinking agent D-ACE 555: 3.0 parts

[0151] Cross-linking accelerator D-ACE 900: 1.8 parts

[0152] Melamine crosslinking agent D-ACE557: 0.5 parts

[0153] Add butanone and tolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com