Hole collapse-incapable high-pressure water ejection drilling and broaching anchor rod pile

A high-pressure water jet and bolt pile technology, which is applied in drill pipe, drilling with liquid/gas jet, drilling pipe, etc., can solve the problem of high manufacturing cost and maintenance cost, complicated drilling method and equipment of mechanical drill pipe, and inability to penetrate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

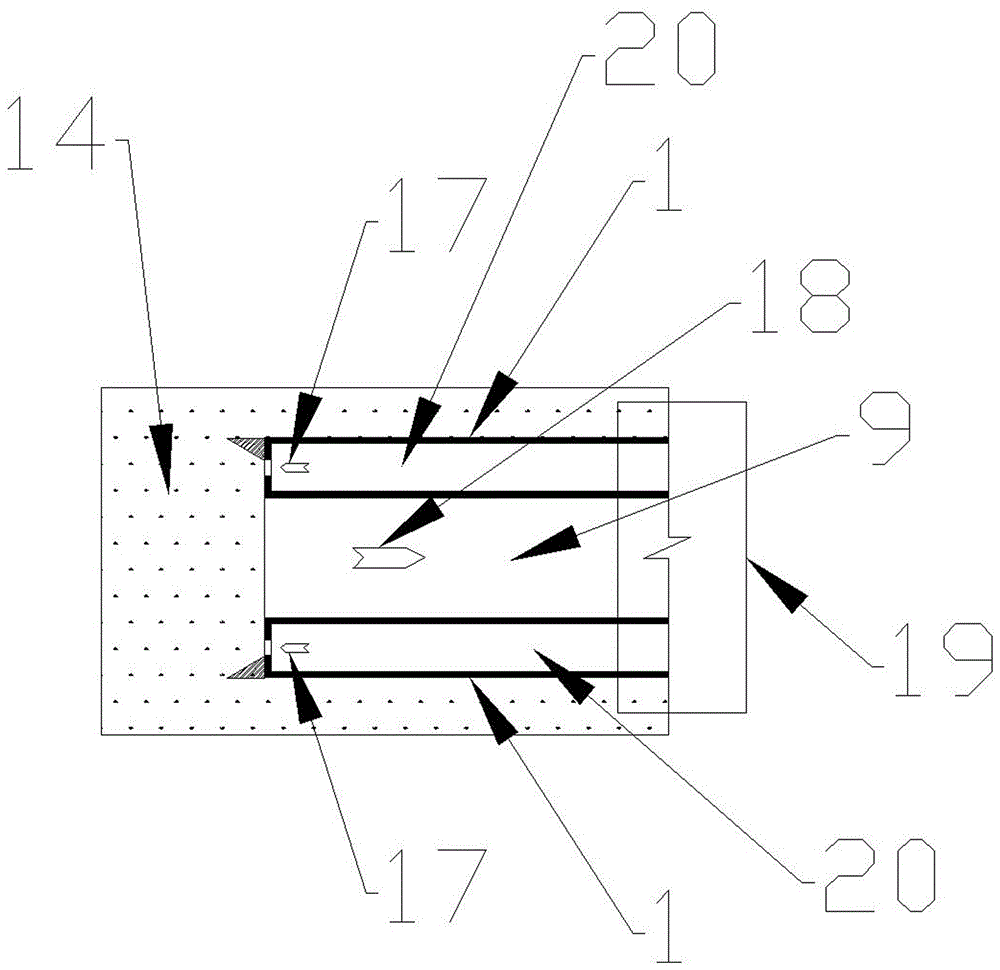

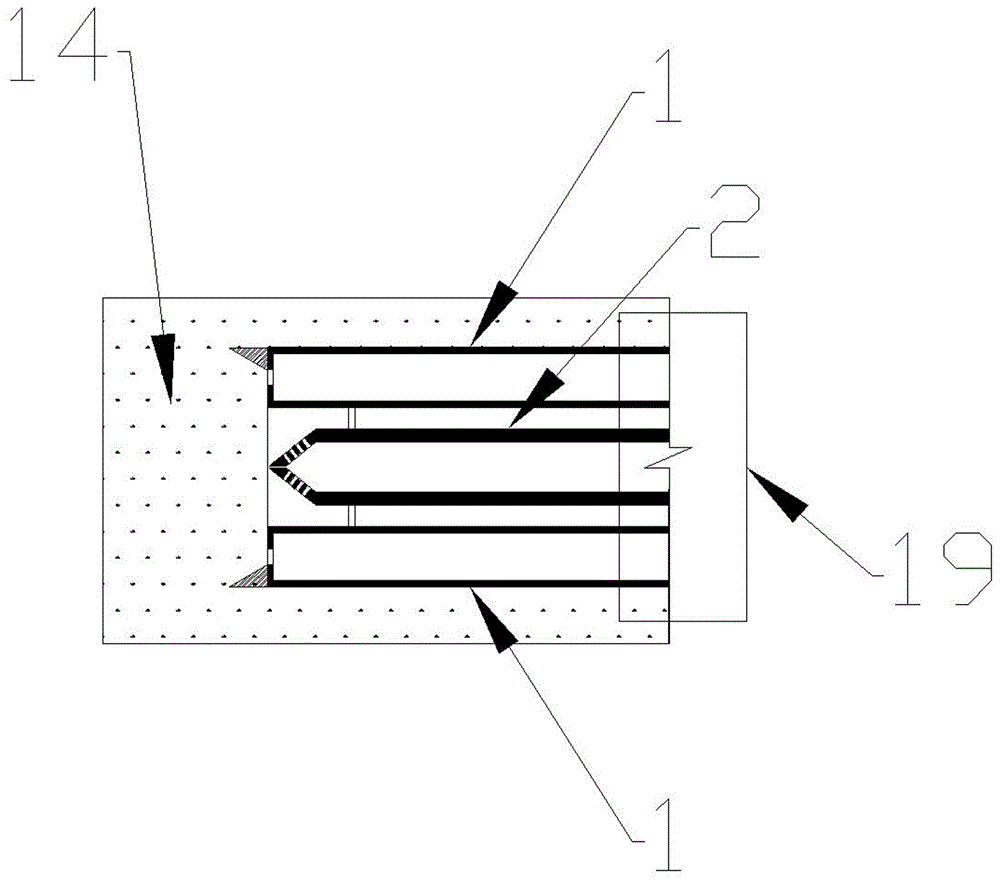

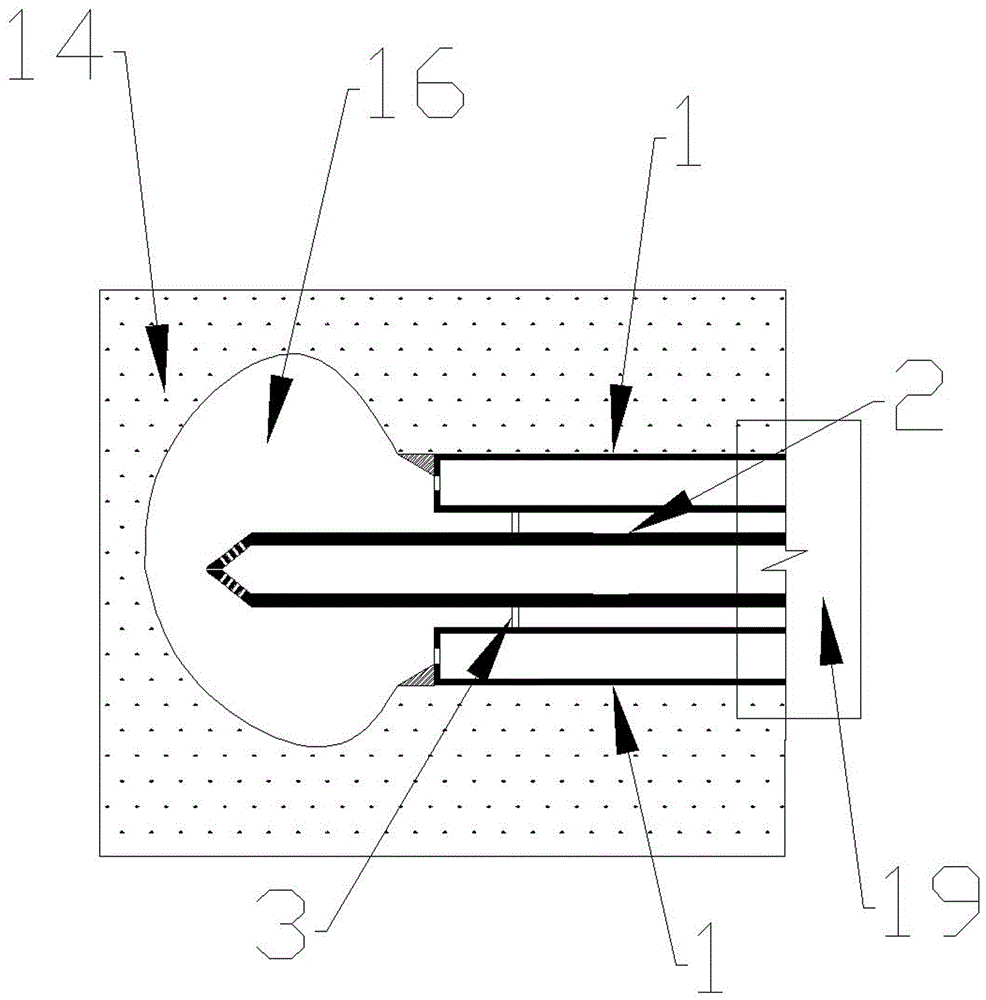

[0014] The summary of the invention has described the specific implementation manner of the present invention in detail, does not repeat here, needs to explain as follows: 1. see figure 1 and Figure 9 , when drilling into the injection drill rod 1 while advancing and spraying high-pressure water, the annular knife 21 cuts into the soil around the pile hole earlier, and the tip of the annular knife 21 is ahead of the position of the injection hole 8, so the annular knife 21 is in the process of spraying. A protective circle is formed for the soil around the pile hole, so the water jet has little disturbance to the soil around the pile hole. 2. See figure 2 and Figure 8 , the front end of the high-pressure nozzle 11 has a front nozzle 13, and the conical surface of the high-pressure nozzle 11 has a plurality of side nozzles 12, the front nozzle 13 cuts the soil of the reaming part forward for a certain distance, and the plurality of side nozzles 12 expands the hole, cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com