Bone induction regeneration membrane as well as preparation method and application thereof

A regenerative membrane and osteoinductive technology, applied in the field of medical materials, can solve the problem that the membrane does not have the function of inducing osteogenesis, and achieve the effect of maintaining mechanical properties, simple steps, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

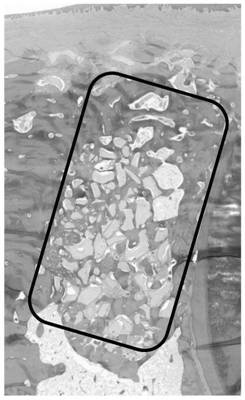

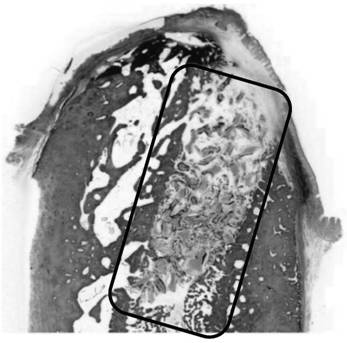

Image

Examples

preparation example Construction

[0098] In order to solve the problem that the existing clinical commonly used membranes do not have the function of inducing osteogenesis or can not directly produce osteogenesis, the present invention uses degradable polymer materials and degradable osteogenic active bioglass, and adopts advanced biomaterial preparation technology - electrostatic Spinning technology to prepare osteoinductive regenerative membrane with nanofiber structure. The osteoinductive regenerative membrane is evenly distributed with polymer fiber filaments and biological glass fiber filaments, and has a three-dimensional network structure similar to extracellular matrix. Specifically, the preparation method includes: preparing the first fiber and the second fiber by electrospinning, and interweaving the first fiber and the second fiber to form an interlaced structure.

[0099] Solvent electrospinning process

[0100] In a specific embodiment, the electrospinning includes: dissolving the polymer mater...

Embodiment 1

[0163] Electrospinning was performed using a solvent electrospinning process.

[0164] The degradable polymer polycaprolactone is dissolved in the organic solvent trifluoroethanol, and a polycaprolactone solution with a concentration of 10% is prepared. Place the polycaprolactone solution in the syringe for use. The tetraethyl orthosilicate was hydrolyzed in hydrochloric acid solution with a pH of 1.5, and the molar ratio of silicon to deionized water was 1:8. After the hydrolysis is completed, triethyl phosphate is added to continue the hydrolysis. After the hydrolysis is completed, calcium acetate and zinc acetate are added to dissolve, and finally a clear solution is obtained. After standing for 6 hours, a biological glass solution was formed, in which the molar ratio of calcium, silicon, phosphorus and zinc was 36:60:8:0.5. Place the bioglass solution in a syringe for later use.

[0165] Place the syringes containing the two components in the electrospinning machine and...

Embodiment 2

[0175] Electrospinning was performed using a solvent electrospinning process.

[0176]Dissolve the degradable polymer polylactic acid and gelatin in the organic solvent trifluoroethanol to prepare a mixed solution of polylactic acid and gelatin with a concentration of 15%, wherein the mass ratio of polylactic acid to gelatin is 1:1. Put the mixed solution of polylactic acid and gelatin in the syringe for later use. The tetraethyl orthosilicate was hydrolyzed in a nitric acid solution with a pH of 1, and the molar ratio of silicon to deionized water was 1:10. After the hydrolysis is completed, triethyl phosphate is added to continue the hydrolysis. After the hydrolysis is completed, calcium chloride and strontium acetate are added to dissolve, and finally a clear solution is obtained. After standing for 10 hours, a biological glass solution was formed, in which the molar ratio of calcium, silicon, phosphorus and zinc was 40:55:8:2. Place the bioglass solution in a syringe for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com