Narrow head terminal, production method of the narrow head terminal and special expanding device

A production method and head terminal technology, which is applied in the connection of permanent deformation, contact manufacturing, electrical connection seat, etc., can solve the problems of reduced strength of the connection, high cost, troublesome processing, etc., and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

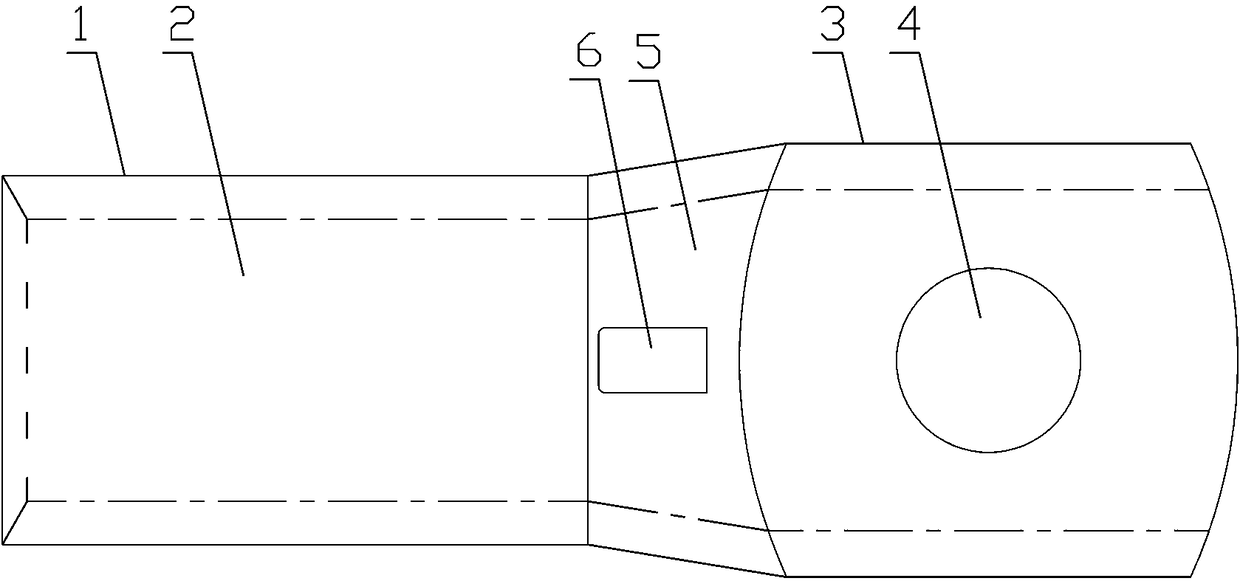

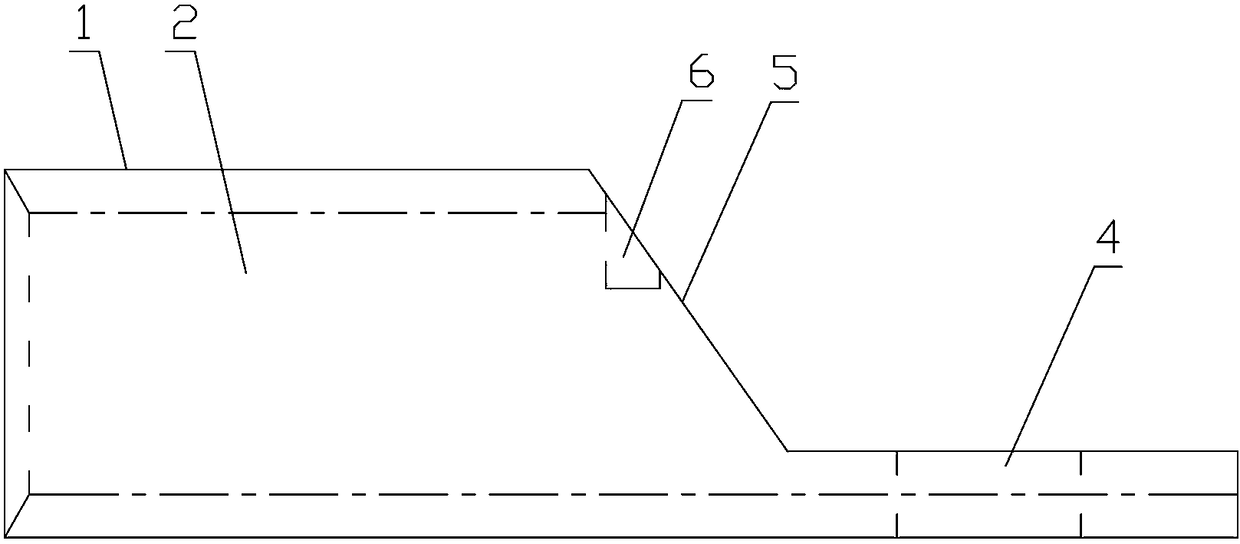

[0034] like Figure 1 to Figure 3 As shown, the narrow head terminal of the present invention is made of copper pipe, and its structure includes: a crimping part 1 and a connecting part 3, the crimping part 1 is cylindrical, and there is an inner cavity 2 in which a power supply wire or cable is inserted; The connecting portion is flat, and the upper and lower end faces are continuous on both sides, and a bolt hole 4 is provided in the middle. After the wire or cable is inserted into the inner cavity of the crimping part, the crimping part is clamped by the clamp, so that the wire or cable is fixed on the crimping part, and the bolt is set in the bolt hole of the connecting part to connect with the connection object .

[0035] Further, an excessive inclined surface 5 is formed between the crimping part and the connecting part, and an observation port 6 communicating with the inner cavity of the crimping part is provided on the inclined surface. The insertion position of the ...

Embodiment 2

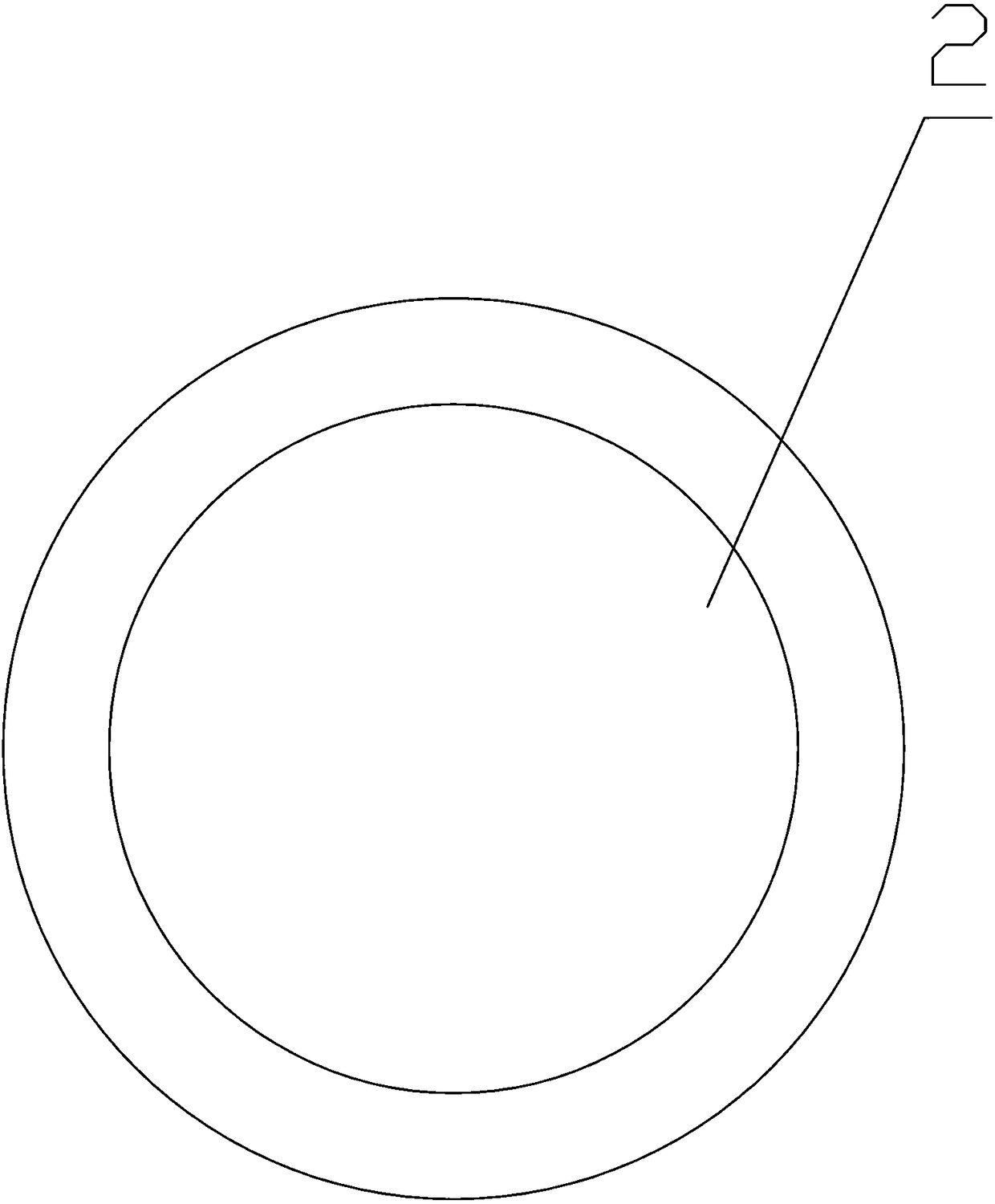

[0037] like Figure 4-6 As shown, a method of producing the narrow-head terminal described in Example 1 of the present invention is taken as an example to produce a copper tube terminal suitable for wires or cables of 70 square meters, that is, the inner diameter of the crimping part is required d=13mm, and outer diameter D=17mm (that is, wall thickness=2mm). Before processing, select a copper tube with an inner diameter of 10mm and a wall thickness of 2-3mm (determined according to the compression ratio of the flaring device) for backup, and then complete the production through the following steps:

[0038] Step 1), pipe cutting: cut the copper pipe to the length required by the corresponding narrow-head terminal. Since the present invention uses two narrow-head terminals for simultaneous production, the copper pipe is cut into twice the corresponding narrow-head terminal, such as the production length L is a narrow head terminal of 57mm, and the length of the copper tube sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com