Automatic threading apparatus for electric cabinet cable protective sleeve

A protective cover and power cabinet technology, which is applied in cable installation, cable laying equipment, cable installation devices, etc., can solve the problems of reducing lubricant, increasing labor workload, and the inability of cables to pass through the protective cover, so as to reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

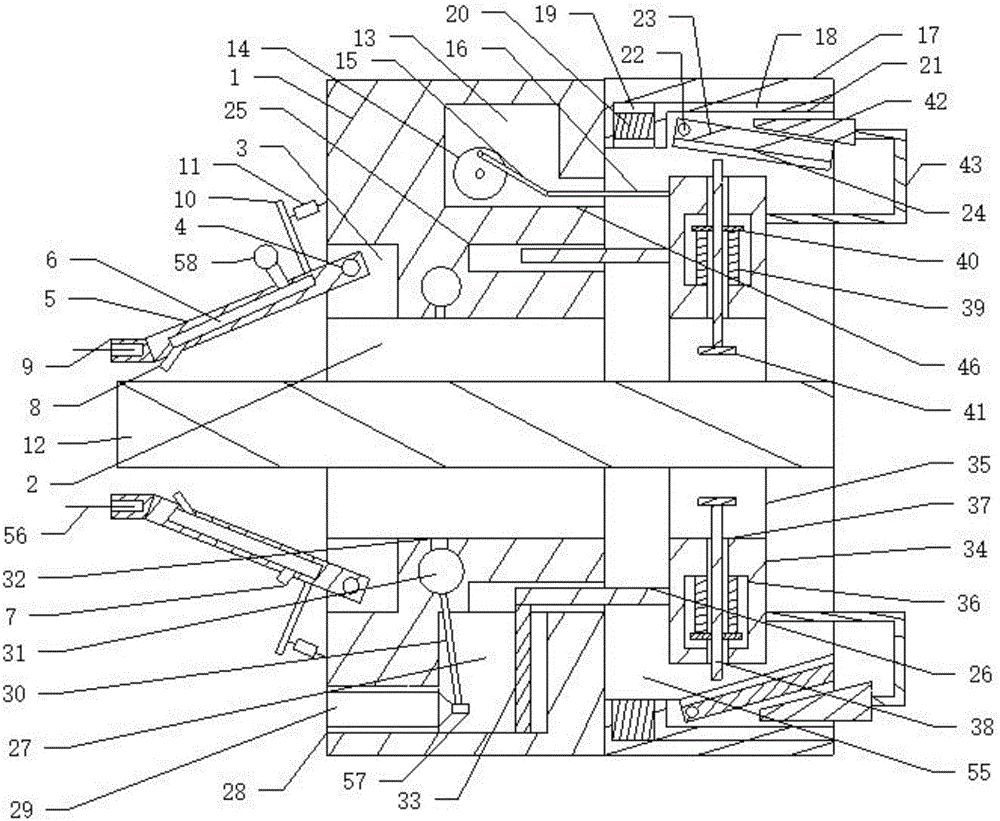

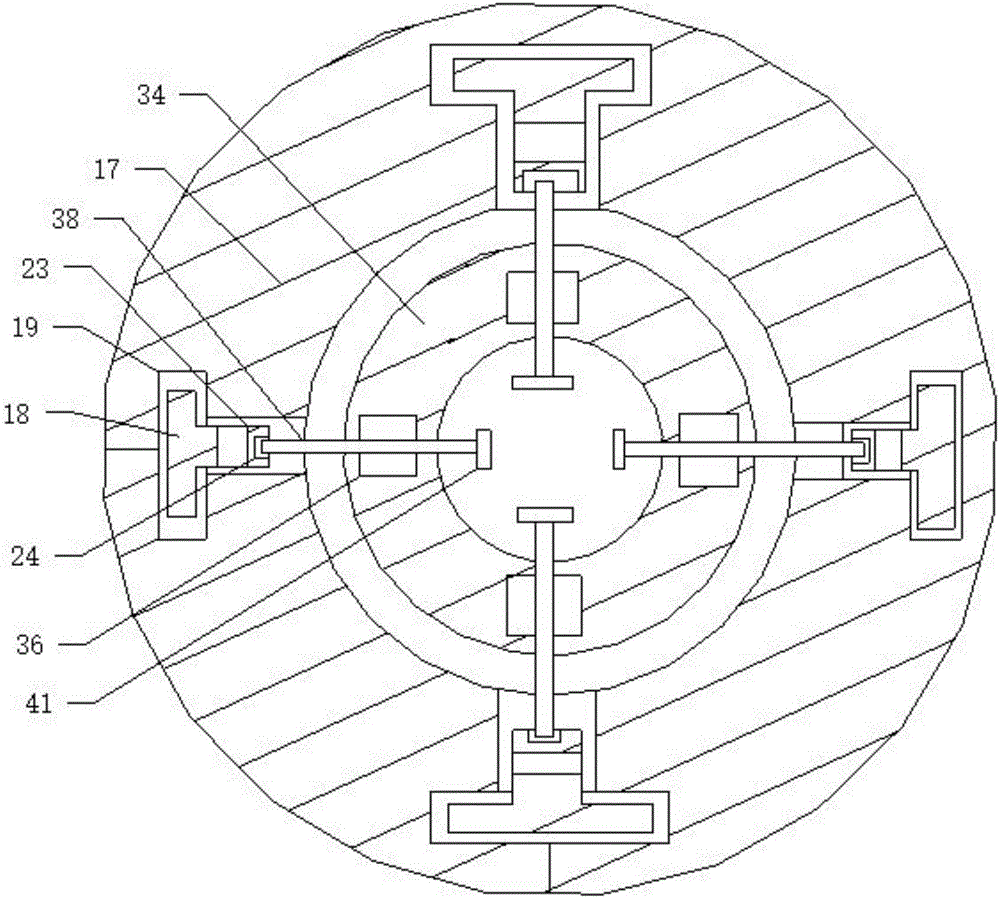

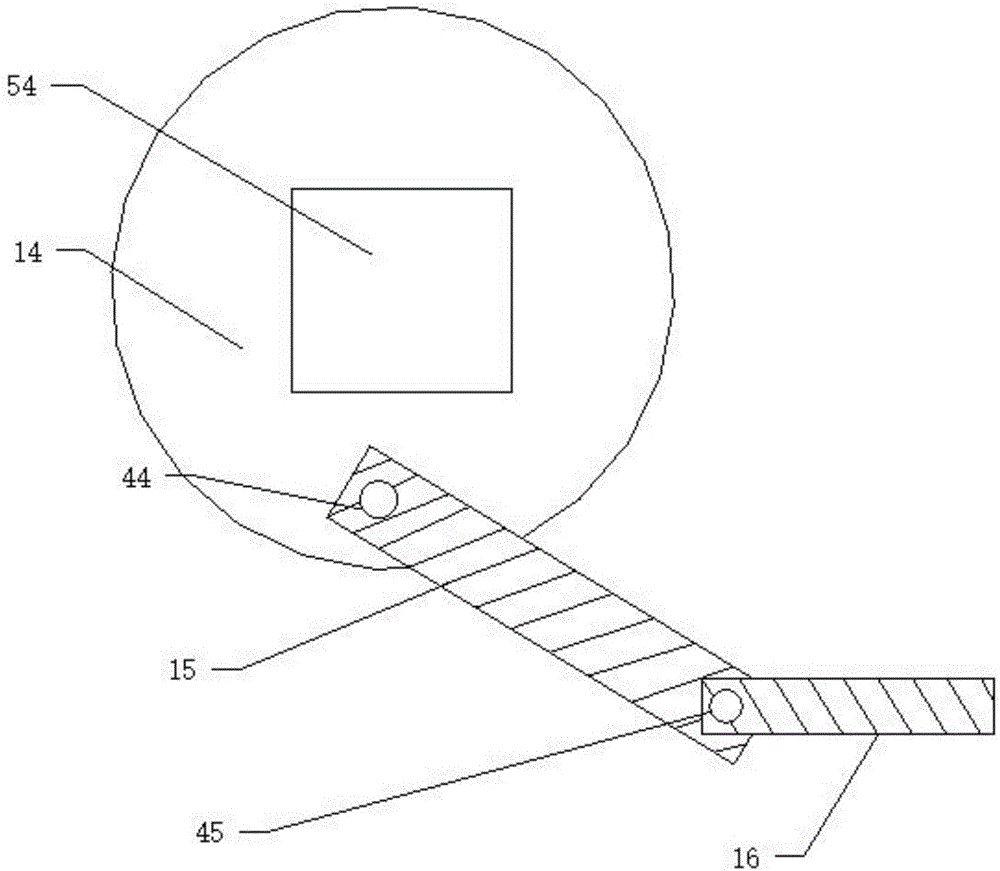

[0024] Such as Figure 1 to Figure 4 As shown, an automatic wire threader for a cable protective cover of a power cabinet includes a cable 12 and a set of protective cover 56 set on the cable 12, and the cable 12 is provided with a lubricating lubricant sprayed by a lubricant bottle 29. The lubricant bottle 29 is provided with a contact pressure end 57, and also includes a first body 1, and the first body 1 is provided with a first wire hole 2 corresponding to the cable 12, so The first body 1 is provided with a circle of first grooves 3, and the first grooves 3 are respectively provided with a rotating first support shaft 5, and the first support shafts 5 are respectively connected with a chuck 9, a The collet 9 correspondingly clamps the protective sleeve 56, and the first support shaft 5 is respectively provided with an exhaust pipe 8 corresponding to the protective sleeve 56, and the first wire hole 2 includes a A spraying hole 32 is arranged on the first body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com